3 Revolutionary Automation and Autonomy Trends: Human Replacement?

Human versatility differentiates humans from machines, or the ability to perform various tasks with reasonable accuracy. For instance, one can be a plumber in the morning and a chef in the afternoon. However, a plumbing machine cannot become a chef in the next million years.

Furthermore, most machines usually perform a small number of tasks with a great deal of control from humans. However, the world is slowly evolving to have machines that can perform tasks without human supervision, giving them significant versatility.

For instance, an autonomous vehicle can drive itself, break when necessary, and even determine the best route without human intervention. Therefore, autonomy and automation quickly evolve to free humans to do other things or relax.

What is Automation?

Automation is a technical term for a process or procedure in which a machine operates with minimal human input or interference. This technology has many applications in factories, robotics, aircraft, ships, cars, and electronics.

Automation has been achieved by applying integrated circuits, pneumatics, hydraulics, and electrical or electronic devices, but mainly in combination. Therefore, a machine or equipment performs related functions after a person has defined the sequence and order to complete the tasks; hence, human input is only supervisory.

What is Autonomy?

Autonomy occurs when a machine performs programmed operations in a particular scenario without human input or intervention during the performance period. The machine is, therefore, termed autonomous.

Autonomy is categorised into two categories: semi-autonomous and fully autonomous. In autonomy, a machine relies on technology to perform tasks. Various technologies, such as sensors, artificial intelligence, machine learning, and deep learning, have been applied, all working together to complete a defined task.

Levels of Automation and Autonomy Technology

There are four levels of automation and autonomy technology, which I will discuss below:

#1) Level Zero

This is the first level, where a human always operates the machine. It is the most common and traditional method of operating heavy construction machinery.

#2) Level One

At this level, the automation starts where the operator is function-specific. The operator can transfer limited control over a specific function to a machine while doing the rest of the operations.

#3) Level Two

Level two applies the concept of semi-autonomous operation. The operator sets the machine to accomplish a specific subset of functions without interaction, leaving him to do the remaining tasks.

#4) Level Three

The last level, level three, is fully autonomous. The operator programs the machine to accomplish all defined tasks without human interaction up to completion. The operator monitors the machine remotely at a command and control centre or on-site for safety and critical operations.

Automation and Autonomy: The Technology Revolution

These two types of technologies have been used in research in various engineering fields since the Second Industrial Revolution, although autonomy is still a new idea. Today, automation is standard in engineering fields due to the increased demand for producing high-quality products and the precision demands in the industry. The intent is to utilise minimal time, less waste of materials, and less strain on the workers.

Engineering Sector: The Great Beneficiary

The engineering sector has then proved to be the primary source of these new technologies, greatly benefiting the engineering fraternity. Due to the interdisciplinary nature of engineering, automation and autonomy, which were considered mechanical and electrical engineering fields, have reaped benefits in the construction, mining, and agricultural engineering sectors.

Their academia, research, and experimentation have modernised the building, mining, and farming fields. Many machinery and robotics inputs have been embraced in these sectors, thus improving the workers’ efficiency and operation.

Automation and Autonomy Technology: Construction

Modern construction and mining now rely on modern, state-of-the-art, high-end engineering facilities with the incorporation of innovative modern construction methods. Heavy plants and machinery are now common in these sectors. These sectors are capital-intensive; hence, every coin saved matters a lot. Therefore, contractors and professionals are always ready to invest in what saves them time and money while promoting efficiency and professionalism.

Revolutionising Automation and Autonomy Technology: Automotive Companies

Various companies worldwide are staking heavily, especially in the new Autonomous Vehicles (AVs) market trend, in their research, testing, development, and commercial manufacturing. Although this has not taken a great wake at Silicon Valley, some companies are starting up or are fully established in this field and have taken steps to make divisions in their companies work on these autonomous projects.

#1) Liebherr

Liebherr, a Swiss-German company, takes the lead with semi-autonomous articulated dump trucks. They have remotely developed a cabinless Liebherr 7XX bulldozer to control with an operator-less wheel loader, the Liebherr L550.

#2) Volvo

Volvo Autonomous Solutions has created a commercially viable fifteen-tonne-capacity autonomous battery-powered haulier, the Volvo TA15. Their setup includes charging stations, cloud communication technology, setup support, and a control tower.

The Volvo setup system allows several vehicles to be assembled as a haulage fleet, incorporating full-size on-road Volvo FH trucks, which are also autonomous. The combination is applicable in a quarry-mining field.

#3) Komatsu

Komatsu has used FrontRunner software to operate its Automated Hauling Systems (AHS) since 2005 in the Chile copper mining field. The software is used for machine guidance and operation, and a separate application called DISPATCH is used for fleet management.

Their automated haulage vehicles include the following diesel/AC-electric-drive hauling trucks:

- Komatsu 830E-AT (255-tonne payload)

- Komatsu 930E-AT (320-tonne payload)

- Komatsu 980E-AT (363-tonne payload)

Their autonomous fleet includes an Innovative Autonomous Haulage Vehicle (IAHV), the weight of which is distributed by the PC7000 shovel. Komatsu noted that the improved operation has reduced load and haul unit costs by 15% and tyre life by 40%.

#4) Caterpillar

Caterpillar is also at the forefront of automation and autonomy. Its D11T bulldozers can be operated semi-autonomously in a group of three by one operator. They are linked to the Command for Dozing AV platform.

They have invested heavily in off-road utility trucks, such as the Caterpillar 797F, which has a payload of 363 tonnes and is used for mining and heavy-duty construction. They have also begun automating the 793F (227-tonne payload) trucks and 789D (181-tonne payload).

For the automation of off-road hauling trucks, Caterpillar has developed the Cat MineStar Command, an automated control AV platform, which the company has also adapted to work with the Komatsu 930E dump truck.

#5) Other Companies

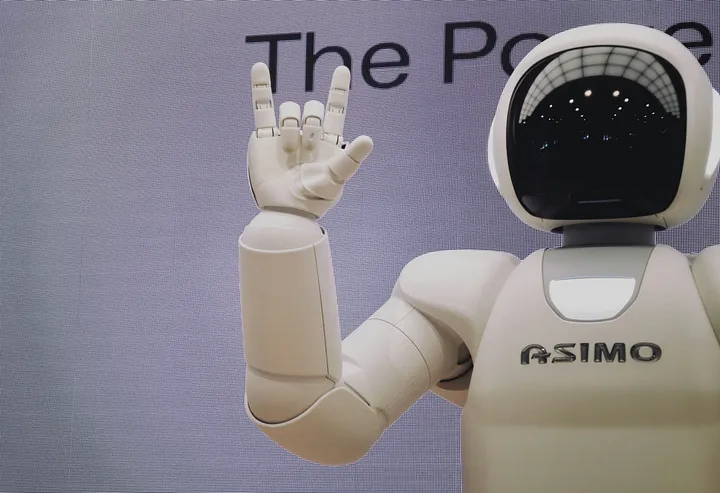

Other top automated and autonomous industry players include Hitachi, Honda, DOOSAN, and Kobelco.

Revolutionising Automation and Autonomy Technology: Individual Startups

Some individuals have also brought autonomous solutions into the industry and formed some startup companies. They include:

#1) Built Robotics

Built Robotics is based in San Francisco, founded by Noah Ready-Campbell. They do not manufacture construction vehicles but sell aftermarket products installed with artificial intelligence devices and software. These automation upgrades make a piece of ordinary equipment operatorless.

#2) Trimble

A similar company to Built Robotics, Trimble, makes machine control solutions for cranes and earthmoving equipment by using Augmented Reality (AR) earthwork displays for excavators that overlay computer-generated 3D Computer-Aided Design (CAD) model imagery over real-world terrain so that operators can keep excavator claws precisely aligned.

Automation and Autonomy Technology: Agriculture

Agriculture has made a significant step in machinery and robotics as applied to the farm world. Those repetitive and labour-intensive jobs can be substituted by a machine, which has more work output than human beings. Harvesting fruits is a good example. It is an intensive, tedious, and delicate task for the farmers since it is very easy to damage the fruit. The following companies have contributed significantly to agricultural equipment automation and autonomy:

#1) Abundant Robotics

The company has created the first-world apple-harvesting machine. Agrobot Robotics has also created a strawberry harvesting robot to harvest fruits according to the farmer’s preference. They use a flexible mobile platform where up to twenty-four robotic manipulators work together to pick the fruits. The robot can harvest eight acres a day, hence eliminating thirty workers.

#2) Bear Flag Robotics

Bear Flag Robotics has developed a tractor automation kit, which farmers can install in their tractors to work autonomously. The kit will stock driverless technology and implement control. Blue River Technologies applies computer vision and robotics to build intelligent solutions for weed control in cotton plants.

Their technology uses the “see and spray” technology, where herbicides are sprayed precisely to the target plant periodically until it dies off, thus preventing herbicide resistance. It eliminates 80% of farmers’ herbicides daily, saving 90% on costs.

#3) American Robotics

The third company, American Robotics, is developing a fully autonomous robot-as-a-service solution for rugged and real-world environments. Through robotics and artificial intelligence innovations, the company has developed an autonomous drone named “Scout,” a base station, and an analytics platform focused on agriculture that provides insights to growers and researchers at high resolutions, speeds, and frequencies never achieved before.

#4) PEAT

PEAT is another startup company that uses a deep-learning-powered image recognition application called Plantix. It detects and recognises various plant defects, helping soil restoration techniques with a pattern detection of 95% accuracy.

#5) Trace Genomics Company

Trace Genomics Company applies machine learning to detect soil weaknesses and strengths. These boost healthy crop production and prevent plant defects. The company specialises in using satellites to predict weather and crop sustainability. It employs machine learning algorithms alongside satellites to predict crop sustainability and evaluate farms to detect the presence of pests and diseases.

#6) Hortau Inc.

Hortau Inc. deals with irrigation management solutions that enable farmers to detect plant stress in real time, ensure optimal plant growth, reduce water and energy consumption, and assess environmental impact. Their system is web-based and wireless, developed by a soil physicist and agricultural engineer in 2002.

Automation and Autonomy Technology: Aiding Technologies

Various technologies are needed for such a revolutionary technological advancement to happen. Continue reading and exploring those technologies below.

#1) 5G Network

The 5G network will also impact the vast autonomous vehicle industry. It will enhance super-fast data exchange via a cloud network when the machines work, facilitating the smooth communication of autonomous vehicles without interference.

Altogether, it will boost operations efficiency, especially in autonomous mining operations. The network will reduce unpredictable downtimes, on-the-fly scheduling, and challenges related to limited field visibility. The new machinery’s infrastructural deployment will enhance expansions and upgrades.

5G will promote safety and emergency handling, real-time data analysis, insights, and predictive analytics with machine learning. The network has high bandwidth, which will work well with the sensors in the field to relay real-time video and data; hence, all equipment will work seamlessly. These will boost remote command and operation from a control centre where everything is monitored.

Augmented and Virtual Reality (AR/VR) videos are sent in real-time to operators on-site. Capgemini SE, France, is an excellent example of a company working on this.

#2) Simulator Games

GIANTS Software created an excellent and elaborate simulator game for gamers to experiment with the natural feel of agricultural mechanisation and the Farming Simulator game. The simulator has helper functions that use artificial intelligence, and the player assigns them tasks to work on a particular operation in a specific field of choice.

This is an excellent and futuristic example of how people will work on their computers while the actual thing is happening in real life. One person can monitor about seven operations effectively in the game.

#3) Sensor Technology

Automation and autonomy have benefited greatly due to the application of sensor technology. Operators or machines can detect obstacles, thus increasing safety at work sites. Using monitors in the cabin mounted to sensors allows the operator to see around the equipment without needing a banksman, even in adverse weather conditions.

All operators can now work more efficiently because there is no need for repeat work. The sensors help determine heights, depths, angles, and speed more accurately than using an operator’s naked eye. Because there are no repeat tasks, this saves fuel and time, which can be used to perform other critical tasks.

Automation and Autonomy Technology: Benefits

Automation and autonomy enhance labour productivity since machines can work continuously at a constant rate, unlike human beings, who are affected by changes in the environment and time of day, such as hot or cold periods during working hours (human factors in machine operations). Below are some of the benefits:

#1) Eradication of Repetitive Tasks

Operators do not have to do mundane tasks; hence, the machines can perform on their behalf as they concentrate on other tasks. This has facilitated reduced resting hours and less tired operators by the end of the day.

#2) 24-Hour Seamless Work Shift

Changing shifts is more manageable, and if autonomous equipment is used, it can work for 24 hours nonstop with a few stops for maintenance, checks, and refuelling; machines do not go for lunch breaks or attend to nature calls.

#3) Reduced Time Wastage

Autonomous machines cut off waiting times during shift changes when some operators can be late or take some time to get accustomed to the task. Machines do not require practice or rehearsal; they do not suffer from boredom or loss of concentration because they are mechanised and computerised.

#4) No Labour Strikes and Go-Slows

Autonomous machines are unaffected by workers’ union interference and labourers’ strikes or go-slows; this saves contractors a lot of time and money.

#5) Reduced Employment Interviews and Labour Contracts

It has also reduced the time needed to interview and test operators for skills and shortened the time needed to look for operators unavailable at specific periods of the year. The contractor does not need labour laws and union agreements to commence a project, saving some months.

#6) Better Performance and Data Reliance Methods

The machines have better and more detailed data reporting mechanisms, which are accurate and can be used to assess work output, fuel consumption, and maintenance schedules through telematics. Human beings can record work hours in which they were instead idling. This can be of great advantage when bidding on thin-margined contracts. Most companies that have embraced this technology have reported 15–20% productivity, which is a huge milestone.

Automation and Autonomy Technology: Challenges

Human beings with automation and autonomy have created various reactions in the market in the last five decades, during which research, modification, and application have been taking place. Numerous challenges have arisen during this period, most of which have benefited its development.

#1) Unable to Handle Unpredictable Scenarios

The main challenge is that autonomous vehicles cannot handle unanticipated scenarios in case of an emergency or change of events, as human beings can. Autonomous vehicles can only perform the preprogrammed task, and if an alteration occurs within that period, it causes errors and malfunctions. Due to these problems, these systems are called “brittle systems.”

#2) Automation System Errors and Malfunctions

“Automation surprise” is also a common factor to consider because sometimes the machines in a system of operation encounter errors that were not anticipated. Hence, the operator may not understand what the system is doing and why it is doing it.

Therefore, the operator gets into a dilemma, which can be an uphill task to comprehend or decipher. This might lead to delays and accidents in a working environment because the equipment might collide, catch fire, or explosions can occur during the process, leading to fatal consequences and losses even to the human operators.

#3) Overreliance on Automated Systems

Due to the reliance on automation, human beings can over-rely on the system’s capabilities and capacities, reducing their dexterity and vigilance during operation. There are also issues like high cognitive workload activity due to one person handling many machines at a go. This has led to problems such as “out of the loop,” where the operators are slow to detect problems and intervene appropriately.

#4) Creation of New Guidelines, Rules, and Regulations

Automation and autonomy have also led to the amendment of legal documents, posing legal risks, especially in the construction sector. Construction sectors are unpredictable due to the nature of the work site and environment. Unlike mining and agricultural fields, the sites are generally space-constrained.

Legal risks include workers’ training and safety, potential accidents if the systems malfunction, and costs associated with equipment maintenance. Provisions must be made during contract-making to consider the risks and compensations in case of an accident, delay, or cost alterations.

#5) Insurance Regulations Challenges

Insurance companies also need to address the issue of compensatory damages arising from autonomous machines and vehicles. Labour unions will also work with contractors to agree on the percentage of autonomous input in contracts to avoid labour unions’ uproars and strikes concerning the reduction of employment.

#6) High Capital Investment

Commercial risks include high capital investment in equipment and machinery, contract bidding price variations, consideration of project cost allocations, unclear return on the project, and when procurement prioritises the lowest bidder.

Automation and Autonomy Technology: The Future Awaits

What does the future look like with the growth in automation and autonomy? There are several possibilities. Humans may build a fully automated world where human labour will be a thing of the past. However, this scenario has its advantages and disadvantages.

First, many people will concentrate on other activities, such as relaxing and enjoying what comes their way from the machines. Companies can also be autonomous, making them highly productive and resilient. However, looking at the scenario keenly, we realise that most machines will be owned by large companies or wealthy individuals who will do what they please with other humans.

Therefore, the poor members of society will be at the mercy of the rich. The alternative scenario would be a world in which men and machines work hand in hand in factories and at home. This is the most plausible scenario because it guarantees a spread of control that makes it hard for a small number of people to control the population entirely.

However, humans will only hold supervisory or design roles. Therefore, the number of people needed in the production lines will decrease significantly, reducing job opportunities.

Wrap Up

Today, we have covered many case scenarios in our discussion, from leading automation companies to individuals dedicating their lives to seeing an advancement in non-human-operated machines. Therefore, we need to prepare adequately for the future of this technology. Everyone should strive to understand the impact of automation and autonomy on the economy and social life.