Drones in Construction Site Inspections: 10 Innovations Improving Safety and Accuracy

The transformation of site inspections by drones is no longer a future promise, but a present-day reality. Across active construction zones, drones in construction are changing how teams capture data, manage risk, verify quality, and track progress. From real-time aerial surveying in construction to intelligent drone monitoring systems, this technology is redefining site visibility, safety, and decision-making.

A New Era of Construction Oversight Through Aerial Intelligence

Construction has always relied on physical presence, manual inspection, and ground-based surveys. That model is now being rewritten. The rise of drone site inspections has unlocked new levels of visibility, speed, and safety that traditional inspection methods simply cannot match.

Instead of climbing scaffolding, walking on unstable ground, or shutting down work to take measurements, engineers and project managers can now deploy compact aerial systems that collect high-resolution imagery, thermal data, and 3D mapping in minutes. This shift explains exactly how drones are transforming site inspections by turning slow, risky, and fragmented processes into fast, centralised, data-driven workflows.

Drones in construction have moved beyond novelty. They are now integrated tools for quality assurance, progress tracking, safety audits, and forensic documentation across small sites and mega infrastructure projects.

How Drones Are Transforming Construction Site Inspections in Practice

This section breaks down the most powerful and proven ways that drones are actively reshaping how inspections are carried out on modern construction projects.

1. Aerial Site Mapping and Real-Time Visual Documentation

One of the clearest examples of how drones are transforming site inspections is the ability to create accurate, up-to-date visual records of a project from above.

In aerial surveying for construction, drones capture high-resolution images and videos that provide a comprehensive view of large and complex sites. These visuals are then stitched together to create orthomosaic maps, 3D site models, and time-lapse documentation. This procedure eliminates blind spots that are common with ground inspections.

Practical improvements include:

- Full-site visibility without physical walkthroughs.

- Faster detection of layout deviations.

- Visual progress tracking for stakeholders.

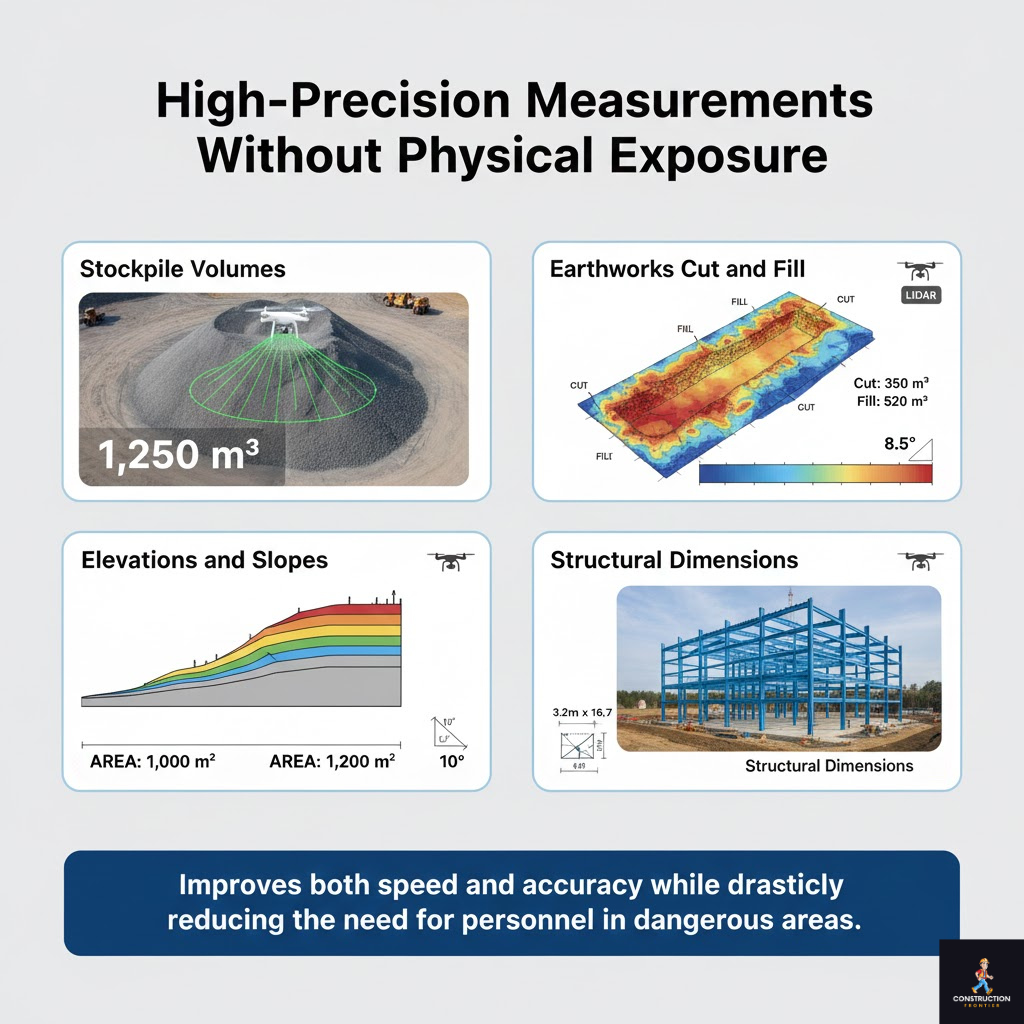

2. High-Precision Measurements Without Physical Exposure

Traditional site measurement requires surveyors to physically access unstable ground, trenches, slopes, and areas with active machinery. Drone site inspections significantly reduce this exposure.

Using photogrammetry and laser scanning (Drone LiDAR or UAV Laser Scanning), drones can measure:

- Stockpile volumes.

- Earthworks cut and fill quantities.

- Elevations and slopes.

- Structural dimensions.

This form of construction inspection technology enhances both speed and accuracy while significantly reducing the need for personnel in hazardous areas.

3. Safer Inspections in High-Risk Environments

Safety is one of the key reasons why drones are transforming construction site inspections, which is gaining global attention due to the safety advantage.

Drones reduce or eliminate some of the duties of inspectors, including:

- High scaffolding and rooftops.

- Active crane zones.

- Confined spaces.

- Unstable excavation areas.

This capability aligns directly with modern health and safety regulations, reducing incident rates. By utilising drone technology for safer construction inspections, companies can lower their insurance exposure and meet stricter compliance requirements.

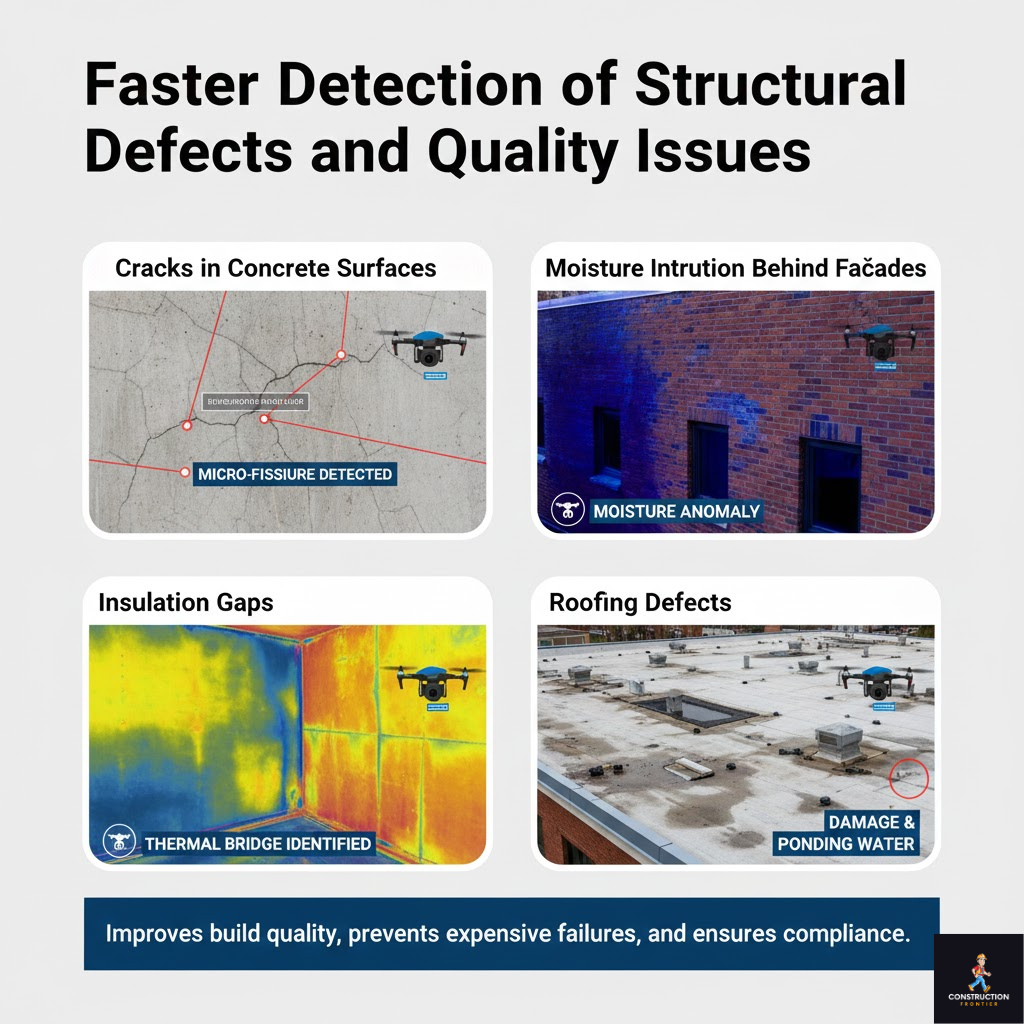

4. Faster Detection of Structural Defects and Quality Issues

Drone monitoring systems now support ultra-high-definition cameras, zoom optics, and thermal imaging. Therefore, drone monitoring allows drone site inspections to identify defects that are often missed by the human eye.

These include:

- Cracks in concrete surfaces.

- Moisture intrusion behind façades.

- Insulation gaps.

- Roofing defects.

- Thermal leaks.

This is one of the strongest examples of how construction companies use drones for site monitoring to improve build quality before problems become expensive failures.

Further read: Revolutionary Smart Sensors in Concrete: 10 Key Metrics They Monitor to Improve Structural Performance.

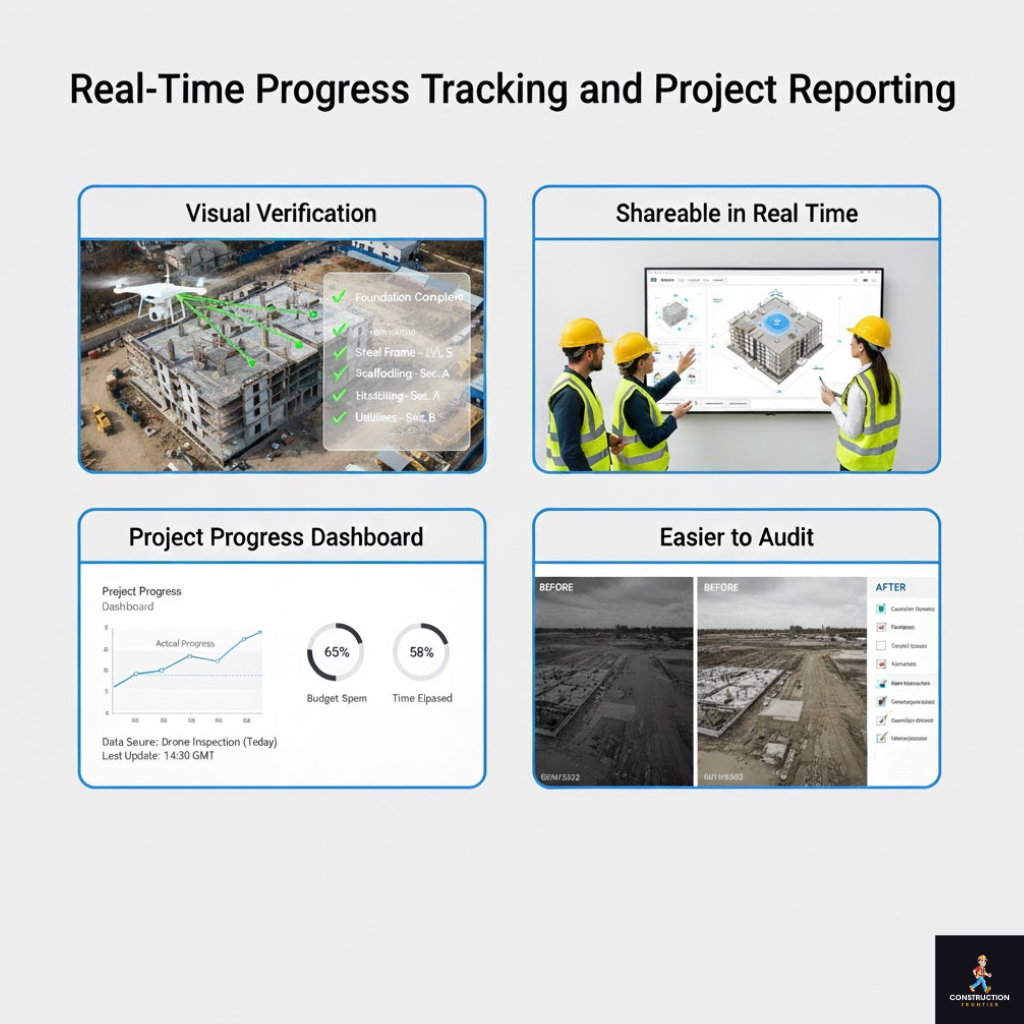

5. Real-Time Progress Tracking and Project Reporting

Drone inspections provide visual proof of work completed versus work scheduled. This helps teams verify claims, manage subcontractors, and build trust with investors and clients.

With construction inspection technology integrated into project platforms, progress data becomes:

- Shareable in real time.

- Verifiable through visuals.

- Easier to audit.

This strengthens collaboration and reduces disputes.

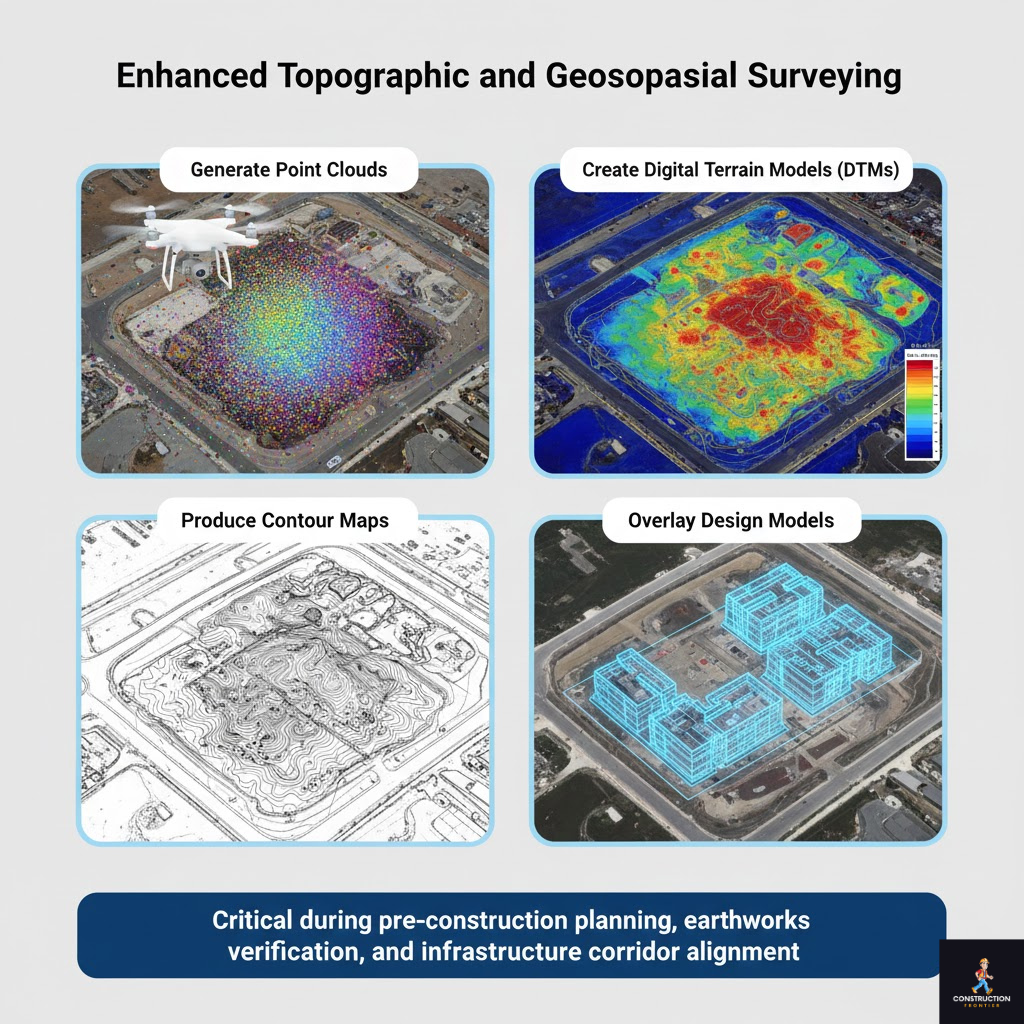

6. Enhanced Topographic and Geospatial Surveying

Aerial surveying in construction using drones has replaced many traditional survey workflows.

Modern drones can:

- Generate point clouds.

- Create digital terrain models (DTMs).

- Produce contour maps.

- Overlay design models over real-world conditions.

This makes drone monitoring systems critical during:

- Pre-construction planning.

- Earthworks verification.

- Infrastructure corridor alignment.

7. Improved Communication Between Field and Office Teams

Drone footage bridges the gap between on-site teams and remote stakeholders.

Engineers, architects, and project managers can now:

- Analyse site conditions remotely.

- Mark up drone visuals.

- Make faster decisions.

This demonstrates another powerful angle of how drones are transforming site inspections through collaboration.

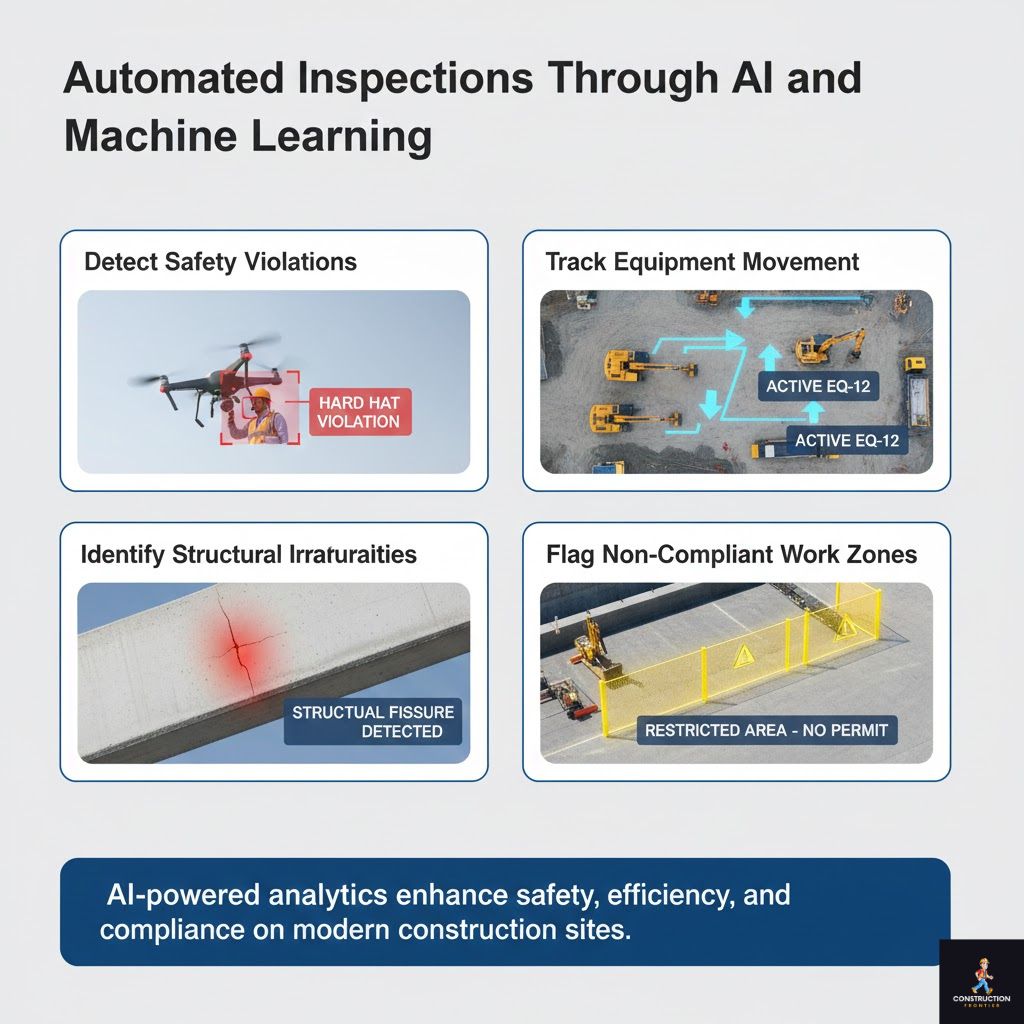

8. Automated Inspections Through AI and Machine Learning

Drone monitoring systems are increasingly integrated with AI-powered analytics.

These systems can automatically:

- Detect safety violations.

- Track equipment movement.

- Identify structural irregularities.

- Flag non-compliant work zones.

This represents the next phase in construction inspection technology.

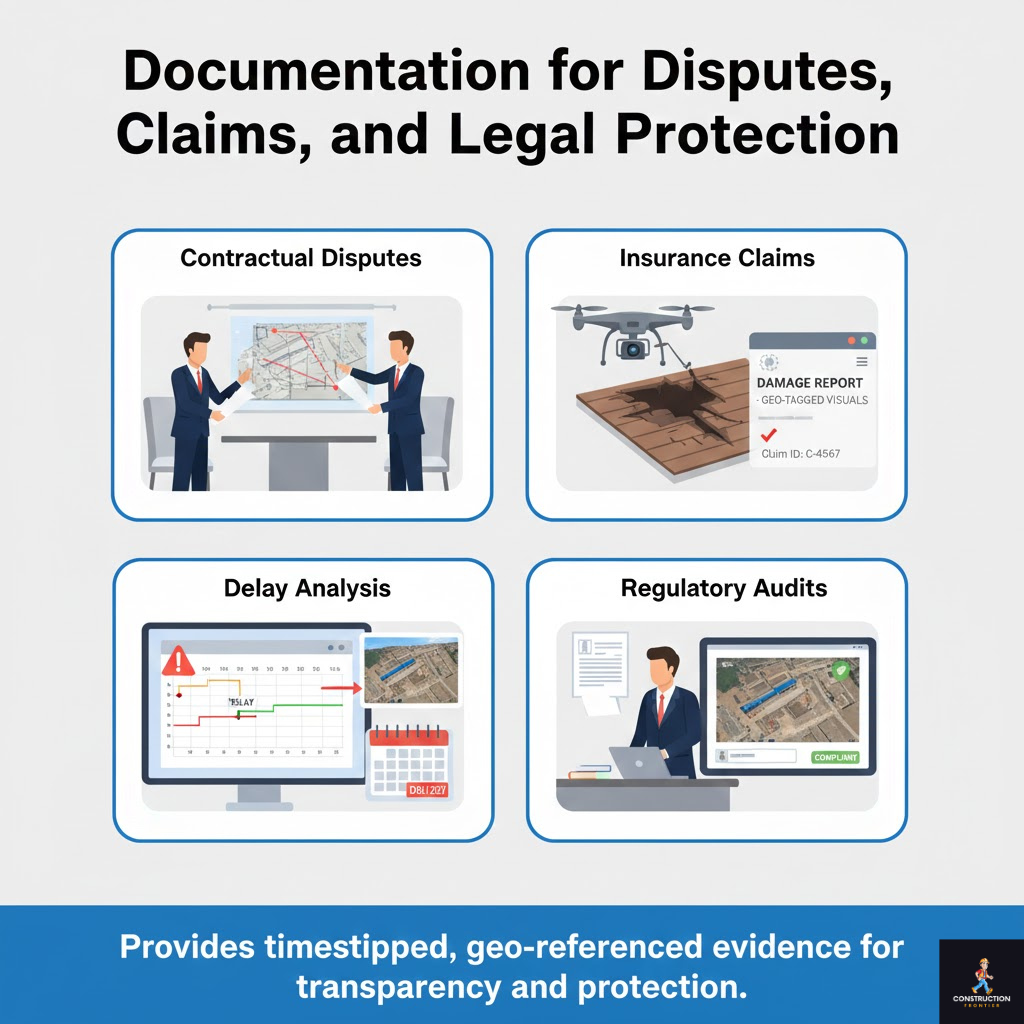

9. Documentation for Disputes, Claims, and Legal Protection

Drone site inspections create timestamped, geo-referenced evidence that can be used in:

- Contractual disputes.

- Insurance claims.

- Delay analysis.

- Regulatory audits.

This has become a core reason why the construction use of drones for site monitoring continues to expand.

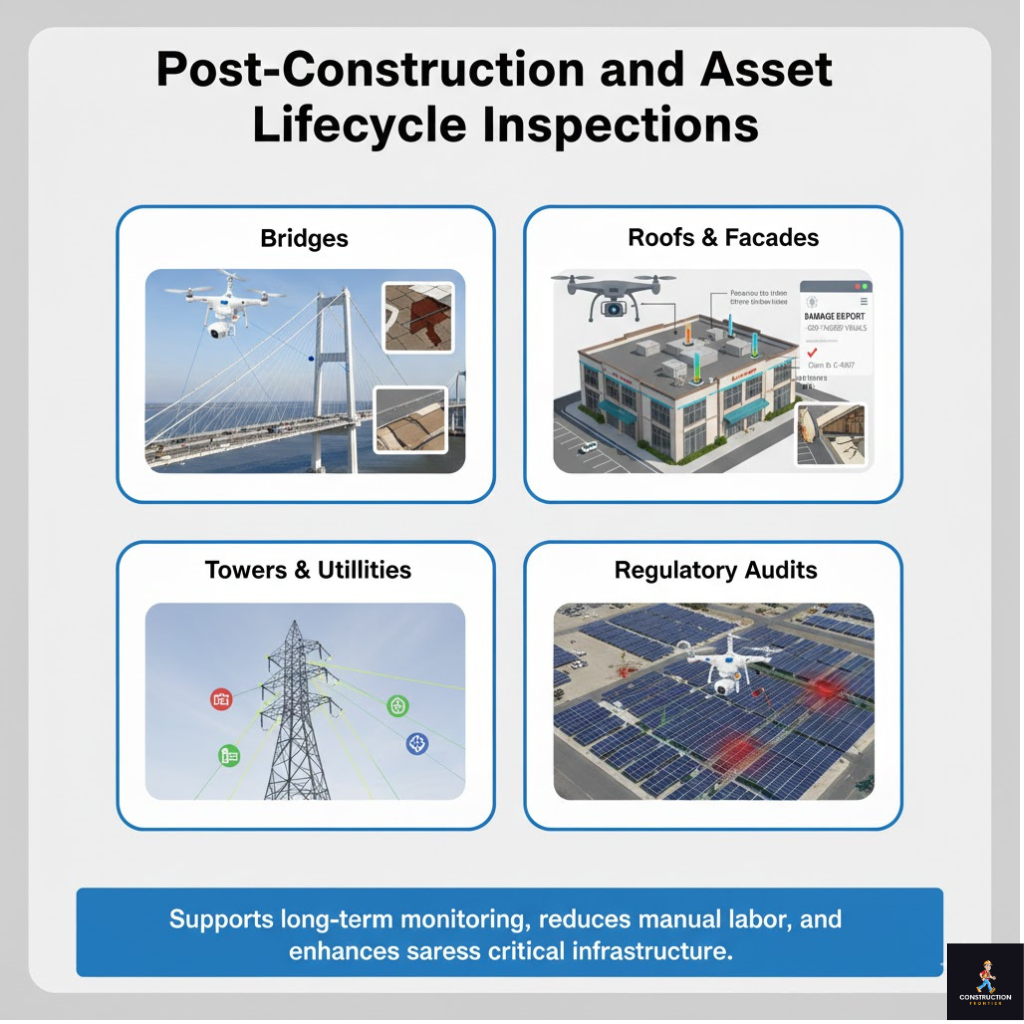

10. Post-Construction and Asset Lifecycle Inspections

Drones are no longer limited to active construction. They are used for inspecting:

- Bridges.

- Roofs.

- Facades.

- Towers.

- Solar farms.

The application of drones supports the future of drone inspections in infrastructure projects, where assets are monitored throughout their lifespan.

Further reading: 10 Remarkable AR and VR in Construction Applications Revolutionising Training and Site Walkthroughs

The Benefits of Using Drones for Site Inspections in Construction

The benefits of using drones for site inspections in construction extend far beyond speed and efficiency. They create measurable improvements in safety, cost, quality, and project transparency.

1. Greater Safety for Workers and Inspectors

Drone technology for safer construction inspections drastically reduces exposure to dangerous work environments. Instead of sending inspectors into unstable structures or elevated zones, drones complete the task remotely.

This leads to:

- Fewer workplace accidents.

- Lower insurance premiums.

- Stronger compliance records.

2. Higher Accuracy and Data Reliability

Drone monitoring systems produce data that is consistent, repeatable, and verifiable. Compared to manual inspections, drone-generated models reduce human error and subjective interpretation.

This improves:

- Design compliance.

- Quality control.

- Decision confidence.

3. Faster Inspections and Reduced Project Delays

Drone site inspections can be completed in hours rather than days. The faster inspection rate reduces downtime and ensures that site activities continue without interruption. Therefore, speed advantage strengthens how drones are transforming construction site inspections across fast-paced projects.

4. Cost Savings Across the Project Lifecycle

Drones reduce the need for some repetitive and monotonous project activities, such as:

- Scaffolding for inspections.

- Temporary access systems.

- Manual surveying labour.

- Rework caused by late defect detection.

The project’s financial impact becomes more significant on large-scale builds.

5. Stakeholder Confidence and Transparency

High-quality aerial visuals enable developers, investors, and regulators to see progress and compliance clearly. Therefore, the stakeholders build trust and reduce conflict with the construction team.

Challenges of Using Drone Site Inspections in Construction

Despite the clear value, companies face real challenges when deploying drones in construction. Below we have highlighted some ot the critical challenges.

1. Regulatory Restrictions and Airspace Limitations

Drone flights are regulated in many countries. Construction companies must comply with:

- Civil aviation rules.

- Flight height restrictions.

- Licensing and pilot certification.

These regulatory restrictions and limitations can delay adoption.

2. Skilled Operator Shortage

Drone monitoring systems are only effective when operated by trained personnel. Many companies struggle to find or train qualified drone pilots who understand construction workflows.

3. Weather and Environmental Limitations

Heavy rain, wind, dust, and extreme heat can affect drone performance. Aerial surveying in construction often relies on reliable weather conditions for accurate data collection.

4. Data Management and Storage Complexity

Drone site inspections generate large volumes of data. Managing, storing, and analysing this data requires a strong IT infrastructure and digital workflows.

5. Privacy and Security Concerns

Flying cameras over active sites can raise concerns about privacy, data protection, and security, especially on sensitive infrastructure projects.

The Future of Drone Inspections in Infrastructure Projects

The future of drone inspections in infrastructure projects is closely tied to automation, AI, and integration with other smart technologies.

In the coming years, drones in construction will likely become:

- Fully autonomous.

- AI-driven for instant defect detection.

- Integrated with BIM and digital twins.

- Connected to smart city platforms.

These changes will further strengthen how drones are transforming site inspections as part of a fully digital construction ecosystem.

Further reading: Automation and Autonomy: A Replacement for Humans with Machinery?

Conclusion: Drones Have Redefined What Site Inspections Can Achieve

The transformation of site inspections by drones is no longer theoretical; it is operational, measurable, and accelerating rapidly. Drone site inspections have proven their value by enhancing safety, increasing speed, improving accuracy, and providing real-time visibility across construction projects. From aerial surveying in construction to intelligent drone monitoring systems, these tools have shifted inspections from reactive tasks to proactive, data-driven processes.

As construction inspection technology evolves, companies that embrace drones early position themselves as safer, smarter, and more competitive. The transformation is not coming; it is already here, and it is reshaping the future of construction oversight at every level.

Call to Action: Discover More at Construction Frontier

Explore deeper insights, expert analysis, and cutting-edge construction technologies at constructionfrontier.com, your trusted source for global construction innovation, digital tools, and infrastructure intelligence.