10 Remarkable Solutions of Fibre Optic Sensing in Infrastructure Maintenance: Enhancing Structural Safety

Fibre optic sensing in infrastructure maintenance is changing how engineers inspect, preserve, and manage bridges, tunnels, pipelines, and buildings. These optical fibre sensors in construction deliver continuous data, early-warning detection, and precise diagnostics so teams can act before minor defects become system failures.

Introduction: Why Fibre Optic Sensing Matters for Infrastructure Safety

Across the world, ageing assets and accelerating demand place infrastructure under pressure. Traditional inspection methods, visual checks, periodic manual surveys, and point sensors are costly, slow, and often detect problems only after damage occurs. By contrast, fibre optic sensing in infrastructure maintenance provides continuous, distributed monitoring that captures strain, temperature, vibration, acoustics, and more along an entire structure. Implementing fibre optic monitoring systems transforms maintenance from reactive and calendar-driven to predictive and condition-based. That shift improves safety, extends asset life, reduces whole-life cost, and gives operators precise data to prioritise interventions.

This article explores ten remarkable fibre optic sensing solutions that infrastructure owners and engineers are using today. Each solution explains how optical fibre sensors in construction work, the practical benefits for roads, bridges, tunnels, and buildings, and the implementation considerations that matter on real projects.

How to Read This Guide (Short Primer)

Before we dive in, a quick note on technology terms you’ll see repeatedly:

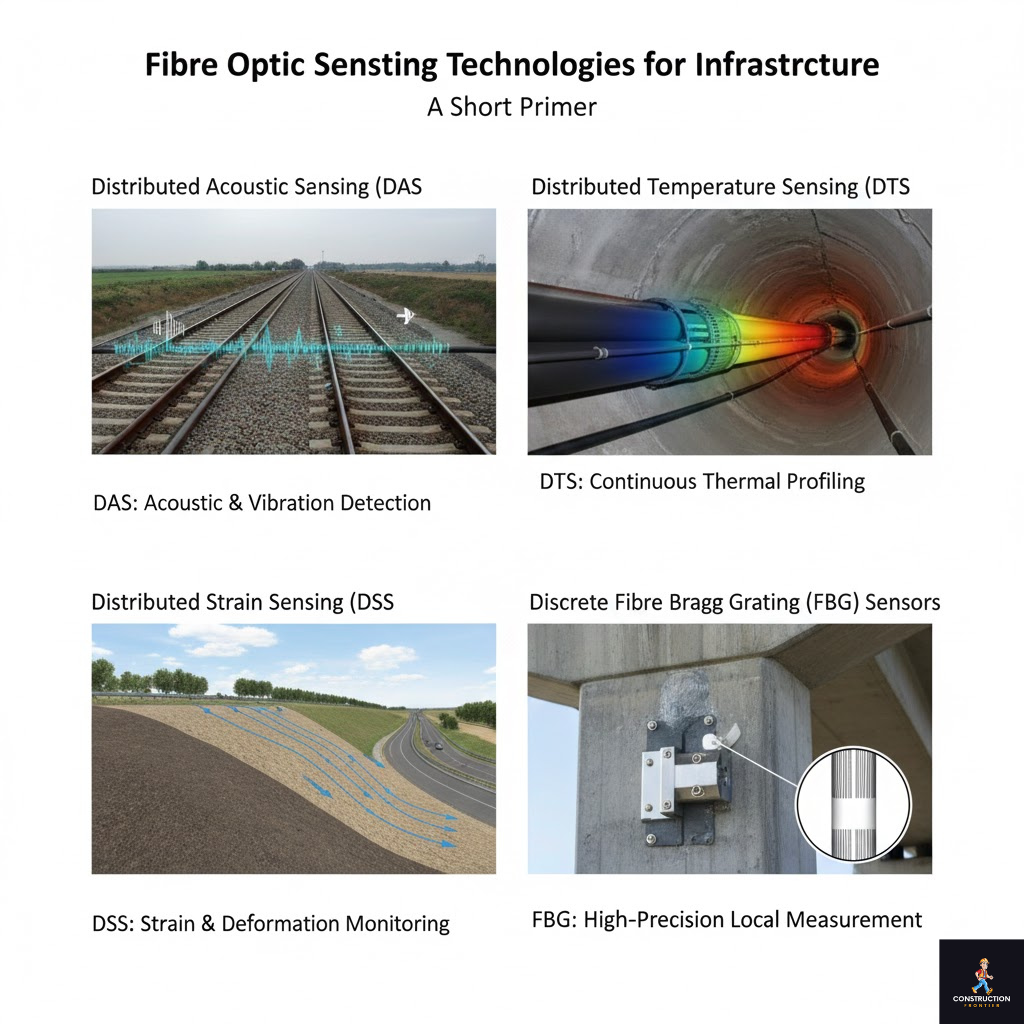

- Distributed Acoustic Sensing (DAS): uses coherent laser pulses to detect acoustic or vibration signals along the fibre length.

- Distributed Temperature Sensing (DTS): measures temperature along fibre using backscattered light; excellent for fire, hot-spot detection, and thermal profiling.

- Distributed Strain Sensing (DSS/OTDR/OFDR): measures strain/shape changes over long distances; suitable for deformation and settlement detection.

- Discrete Fibre Bragg Grating (FBG) sensors: short fibre segments that reflect specific wavelengths, ideal for precision local measurement (bridges, supports).

Each application below includes a short technical spec (sensing type, resolution, range, ruggedisation, power/data needs) and a vendor-agnostic pilot plan (objectives, scope, success metrics, timeline, sample budget indicators).

How We Reviewed Fibre Optic Sensing Solutions

To evaluate fibre optic sensing in infrastructure maintenance, focus on four practical criteria: sensing capability (what the system measures), spatial coverage (point vs distributed), data fidelity and analytics, and operational resilience (installation, environment, and lifecycle costs). The solutions below are described with real-world application notes and balanced pros/cons to help technical teams decide what fits their asset class and budget.

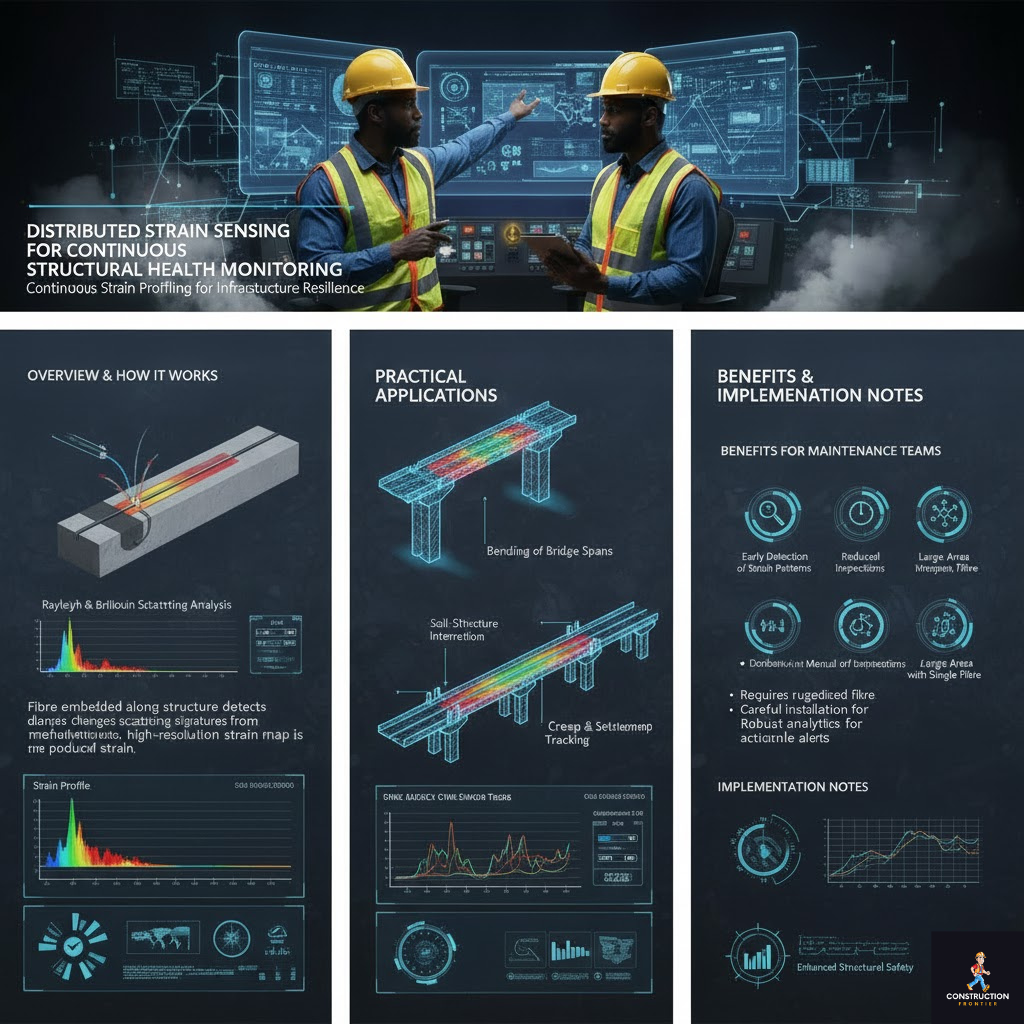

1. Distributed Strain Sensing for Continuous Structural Health Monitoring

Distributed strain sensing (DSS) is one of the core fibre optic monitoring systems used in civil infrastructure. Using Rayleigh or Brillouin scattering principles, a single optical fibre acts as a continuous sensor along its entire length. That means engineers can measure strain profiles continuously over tens of kilometres, pinpointing deformation zones without placing countless discrete gauges.

Overview and how it works

A fibre embedded or bonded along a bridge girder, tunnel lining, or building column returns scattering signatures that change with mechanical strain. Analysing shifts in these signals produces a continuous, high-resolution strain map.

Practical applications

- Detecting progressive bending of bridge spans under changing traffic loads.

- Monitoring soil-structure interaction on piled foundations.

- Tracking long-term creep and settlement in concrete viaducts.

Benefits for maintenance teams

- Early detection of unusual strain patterns before visible cracking.

- Reduced the need for manual inspections at multiple isolated points.

- Ability to monitor large areas with a single fibre installation.

Implementation notes

DSS requires ruggedised fibre and careful installation to ensure bond quality. Data volumes are significant; robust analytics are needed to convert strain fields into actionable alerts.

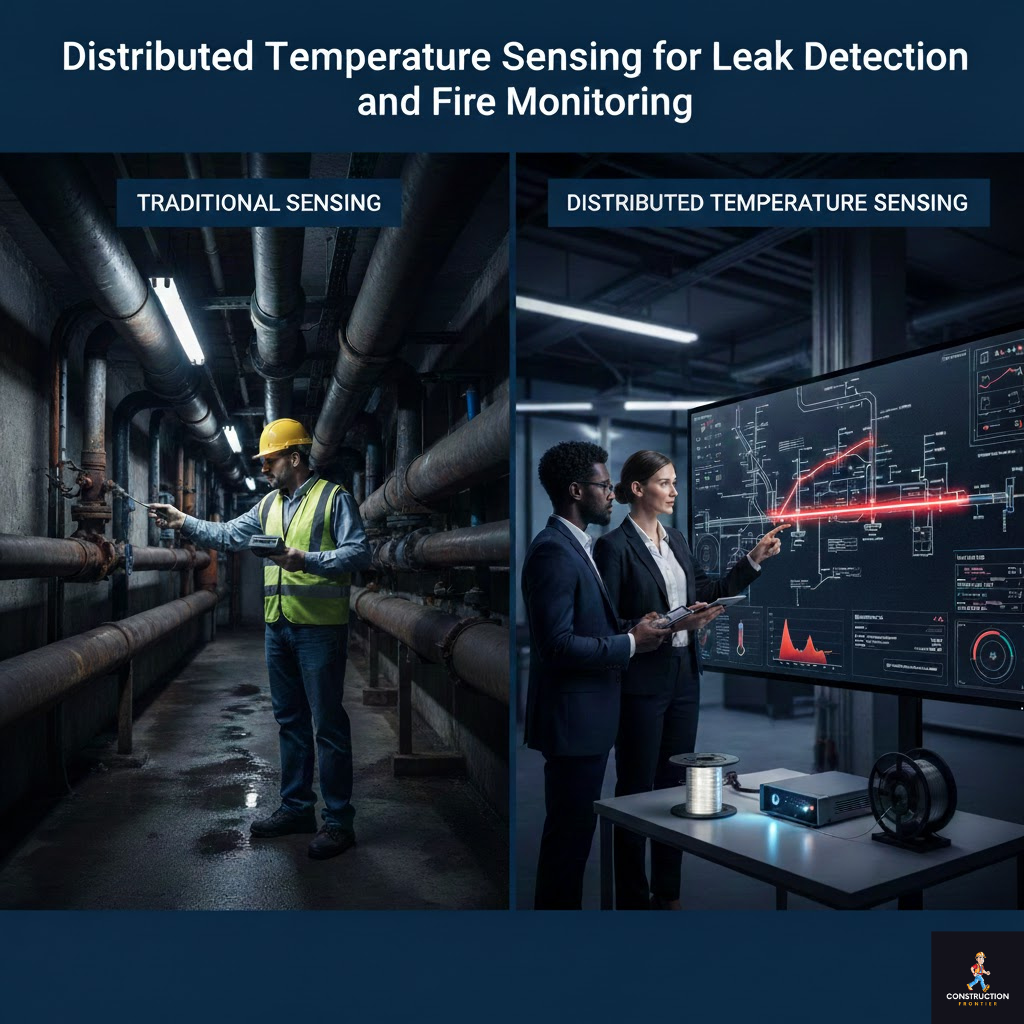

2. Distributed Temperature Sensing for Leak Detection and Fire Monitoring

Distributed temperature sensing (DTS) uses optical fibre to measure temperature profiles along linear assets with great precision. For pipelines, tunnels, and buried utilities, detecting localised temperature anomalies can reveal leaks, hydrant failures, or fire events far earlier than human detection.

Overview and how it works

DTS typically uses Raman scattering. A laser pulse travels down the fibre, and backscattered light is analysed to derive the temperature at discrete points along the fibre length.

Practical applications

- Continuous leak detection on oil, gas, and water pipelines.

- Early detection of electrical faults or fires in tunnels and subway systems.

- Monitoring temperature gradients in buried district heating lines.

Benefits for maintenance teams

- Immediate localisation of leaks or thermal faults by kilometre or metre accuracy.

- Continuous 24/7 surveillance is critical for remote or hard-to-access assets.

- Reduced environmental impact through faster leak response.

Implementation notes

Fibre placement close to the element of interest is crucial. DTS works best where temperature change is a clear failure signature and requires calibration to distinguish diurnal or seasonal thermal shifts.

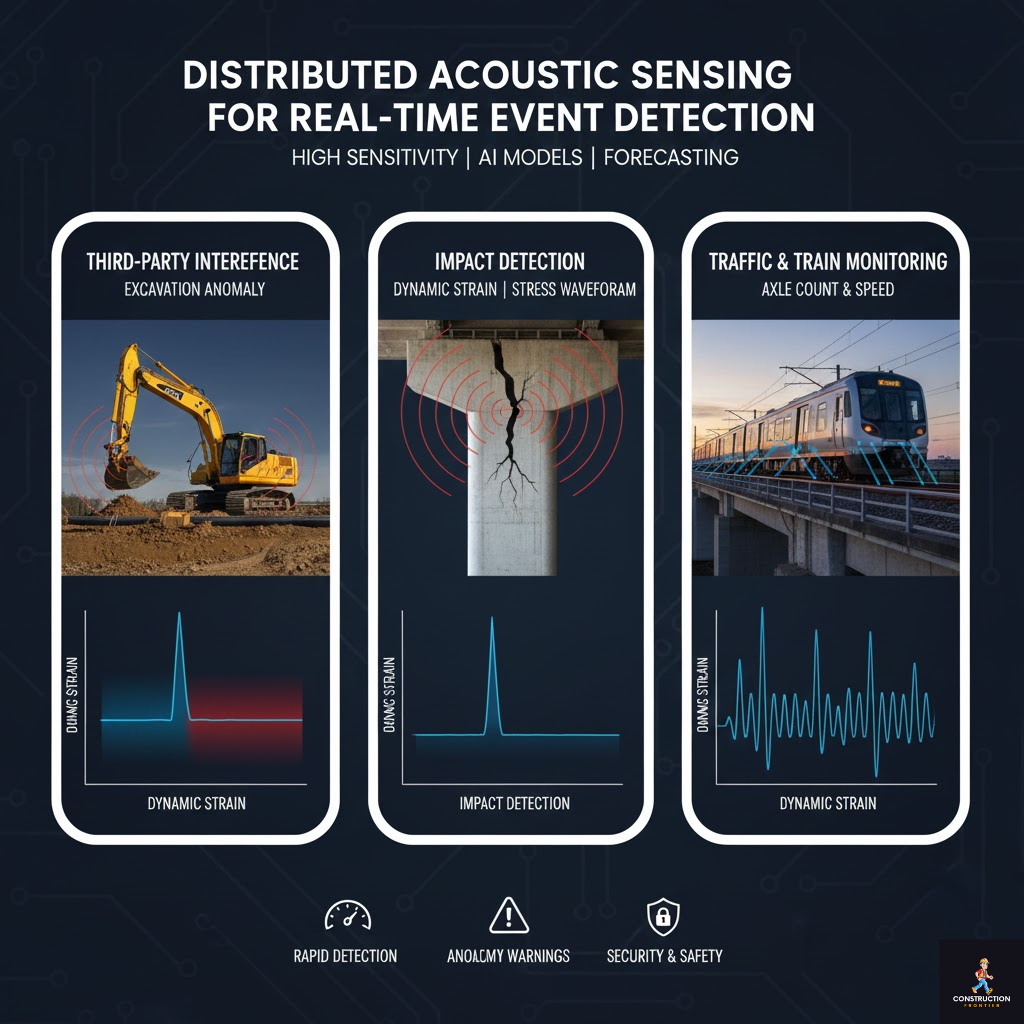

3. Distributed Acoustic Sensing for Real-Time Event Detection

Distributed acoustic sensing (DAS) turns a fibre optic cable into a long microphone, detecting acoustic and vibrational events along the fibre. DAS systems sense minute dynamic strain changes and can be used for intrusion detection, traffic monitoring, and early structural anomaly warnings.

Overview and how it works

DAS analyses backscattered Rayleigh signals to resolve dynamic changes in strain at high frequency. Each meter of fibre can report sound-like signatures that reflect operational events.

Practical applications

- Detecting third-party interference or excavation near buried pipelines (third-party damage).

- Monitoring impact events on bridges or sudden collapses.

- Real-time detection of train operations or heavy vehicle crossings for asset management.

Benefits for maintenance teams

- High sensitivity to transient events that static strain sensors miss.

- Rapid detection of anomalies such as impacts, crack propagation noises, or active leaks.

- Valuable for security and safety monitoring in addition to structural health.

Implementation notes

DAS produces dense time-series data, and operational teams must tune alarm thresholds and filter background noise. It is particularly powerful when correlated with other sensing channels.

4. Quasi-Distributed Point Sensors Using Fibre Bragg Gratings

Fibre Bragg Gratings (FBGs) are point sensors written into an optical fibre that reflect specific wavelengths, shifting with strain and temperature. Many FBGs can be multiplexed along a single fibre for targeted monitoring of critical structural locations.

Overview and how it works

Individual FBGs are laser-inscribed at set points; each grating reflects a unique wavelength. Changes in strain or temperature at the grating shift the reflected wavelength, which an interrogator reads.

Practical applications

- Monitoring expansion joints, bearings, or anchor bolts in bridges.

- Precise monitoring of tunnel lining segments at curvature transitions.

- Instrumenting historic buildings where discrete monitored locations are critical.

Benefits for maintenance teams

- Very high accuracy and stability at targeted locations.

- Low power consumption and immunity to EMI (electromagnetic interference).

- Easy multiplexing enables dozens of FBGs on one fibre run.

Implementation notes

FBGs are best where specific, high-confidence readings are required. They complement distributed systems by providing calibration points and fail-safe measurements.

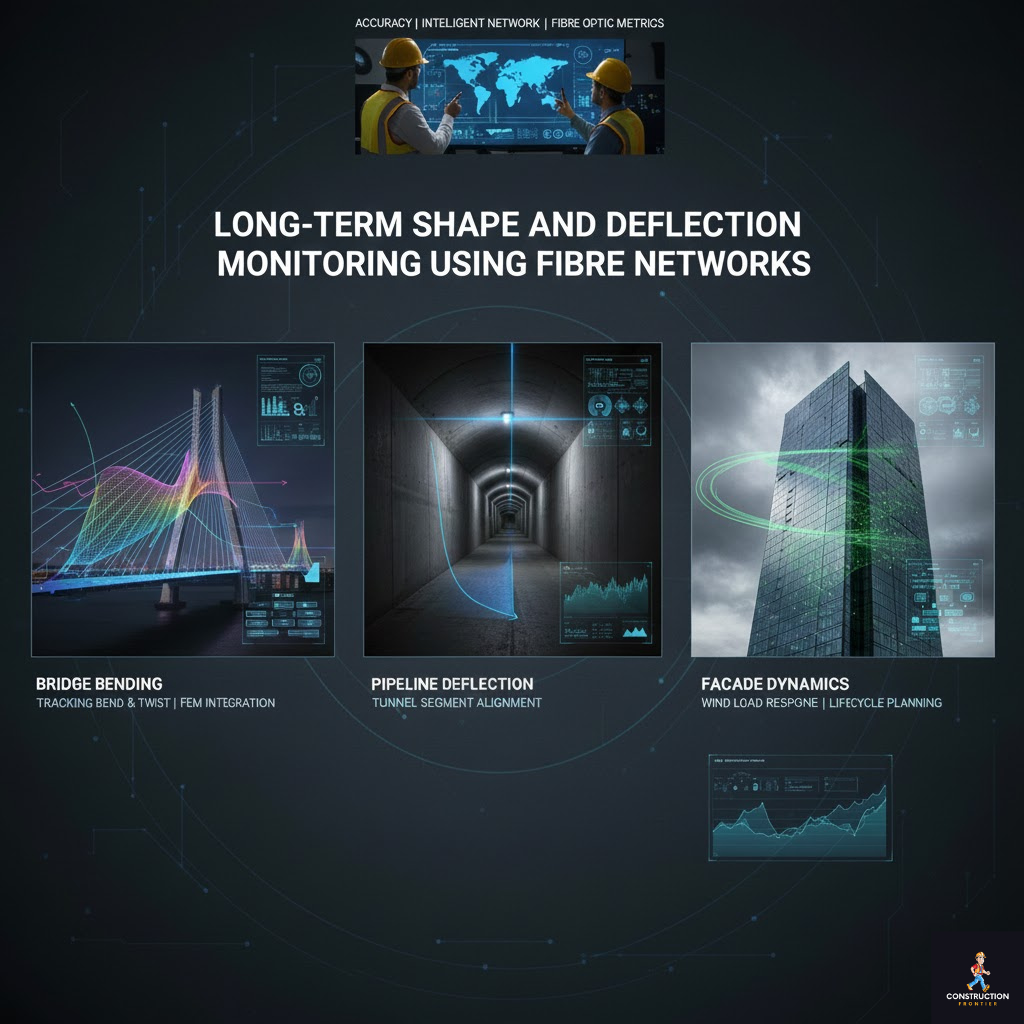

5. Long-Term Shape and Deflection Monitoring Using Fibre Networks

Combining distributed strain sensing and intelligent data fusion allows operators to reconstruct structural shape and deflection patterns over time. Rather than isolated strain values, this approach yields a picture of how an object deforms under loads across seasons and traffic cycles.

Overview and how it works

Fibres run along multiple structural paths; computational models convert distributed strain fields into global deformation geometries.

Practical applications

- Continuously tracking bending and twist in long-span bridges.

- Monitoring deflection in long culverts and pipeline spans.

- Assessing dynamic deflection response of high-rise façades under wind loads.

Benefits for maintenance teams

- Quantitative, trendable deformation metrics for lifecycle planning.

- Improved validation of design assumptions and retrofit needs.

- More substantial evidence for load rating and permitting decisions.

Implementation notes

Model calibration is essential. Engineers must combine fibre data with FEM (finite element method) models to translate strain fields into spatial displacements reliably.

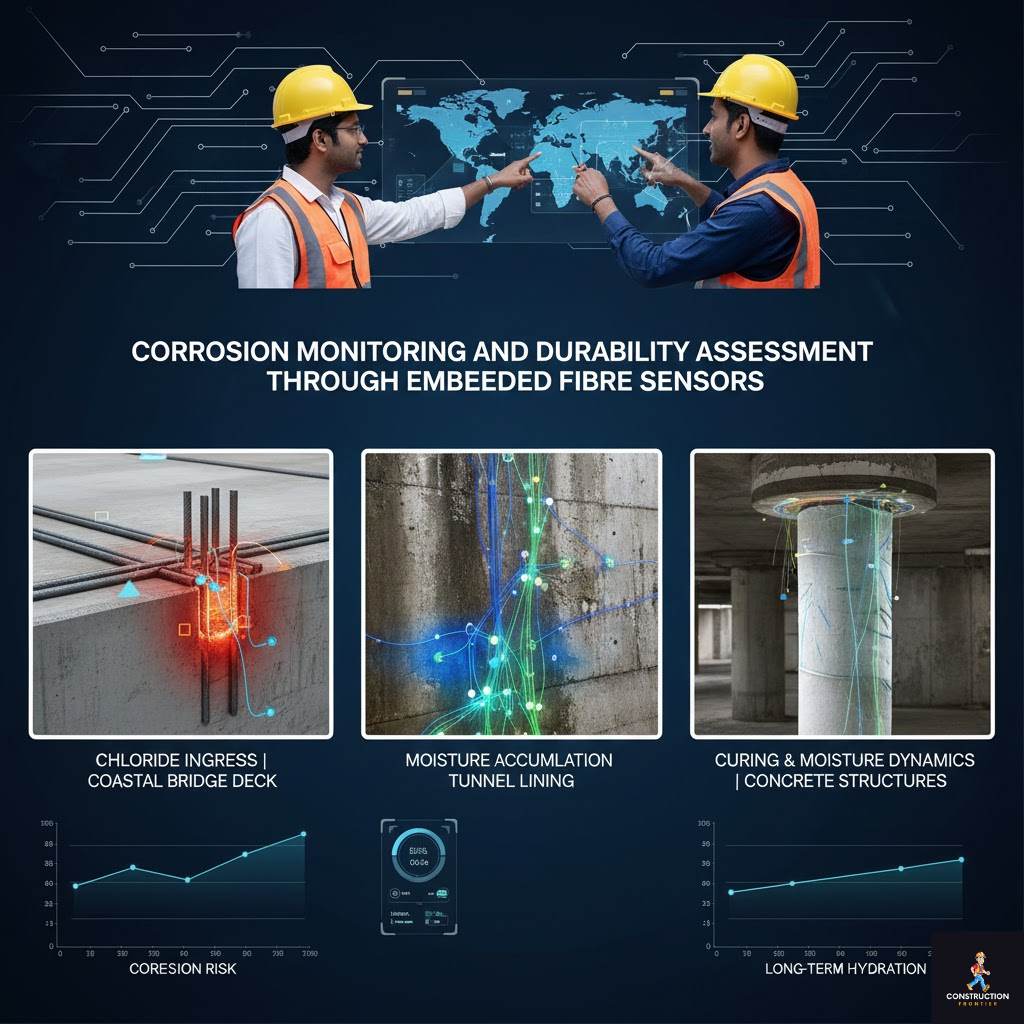

6. Corrosion Monitoring and Durability Assessment Through Embedded Fibre Sensors

Corrosion and material degradation are major drivers of infrastructure failure. Optical fibre sensors embedded near reinforcement or material interfaces can monitor electrochemical indicators and local environmental parameters to infer corrosion risk.

Overview and how it works

Sensors measure parameters such as pH, moisture content, or temperature at concrete–steel interfaces, often combining fibre sensors with chemical coatings or distributed measurements.

Practical applications

- Early warning of chloride ingress in coastal bridge decks.

- Monitoring moisture accumulation in tunnel linings.

- Assessing curing and long-term moisture dynamics in concrete structures.

Benefits for maintenance teams

- Targeted monitoring for the most corrosion-prone components.

- Better prioritisation of protective measures (cathodic protection, coatings).

- Enhanced life-cycle models based on observed environmental exposure.

Implementation notes

This approach sometimes requires hybrid sensor systems (optical plus electrochemical) and careful installation during construction or retrofit.

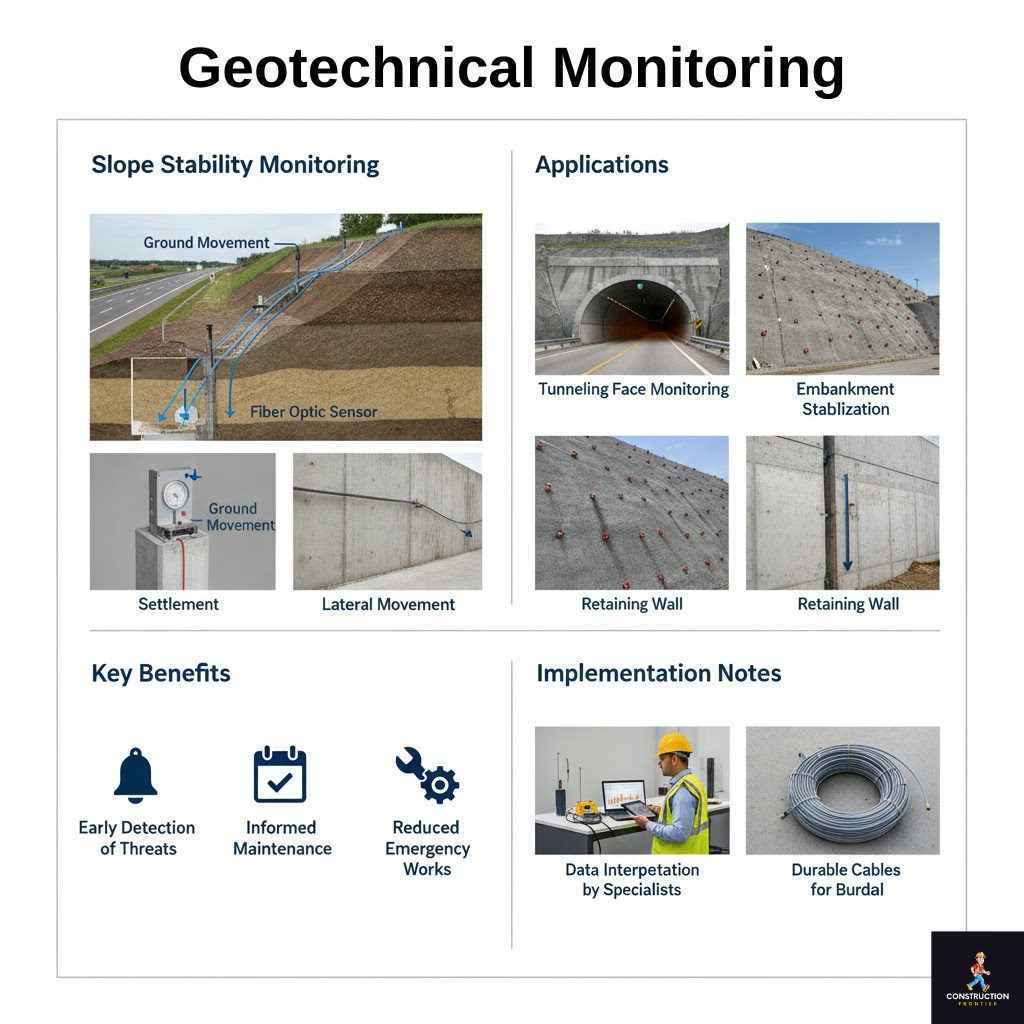

7. Geotechnical Monitoring: Slope Stability, Embankments and Pile Behaviour

Fibre optic sensing in infrastructure maintenance extends beyond the structure to its ground. Distributed fibres in embankments, retaining walls, or within boreholes reveal settlement, strain, and pore-pressure proxies.

Overview and how it works

Fibres are laid in ground anchors, along piles, or within geotextile layers. Distributed readings capture differential movements over length, supporting slope stability models.

Practical applications

- Detecting progressive movement in earth embankments near highways.

- Monitoring settlement around tunnelling faces and station boxes.

- Tracking lateral movement in retaining structures and shoring systems.

Benefits for maintenance teams

- Early detection of ground-induced threats to rail and road corridors.

- Better coordination between structural repairs and geotechnical remediation.

- Reduced emergency works via staged, evidence-driven interventions.

Implementation notes

Environmental protection of fibres is essential; cables must be selected for burial and mechanical stresses. Data interpretation often requires geotechnical specialists.

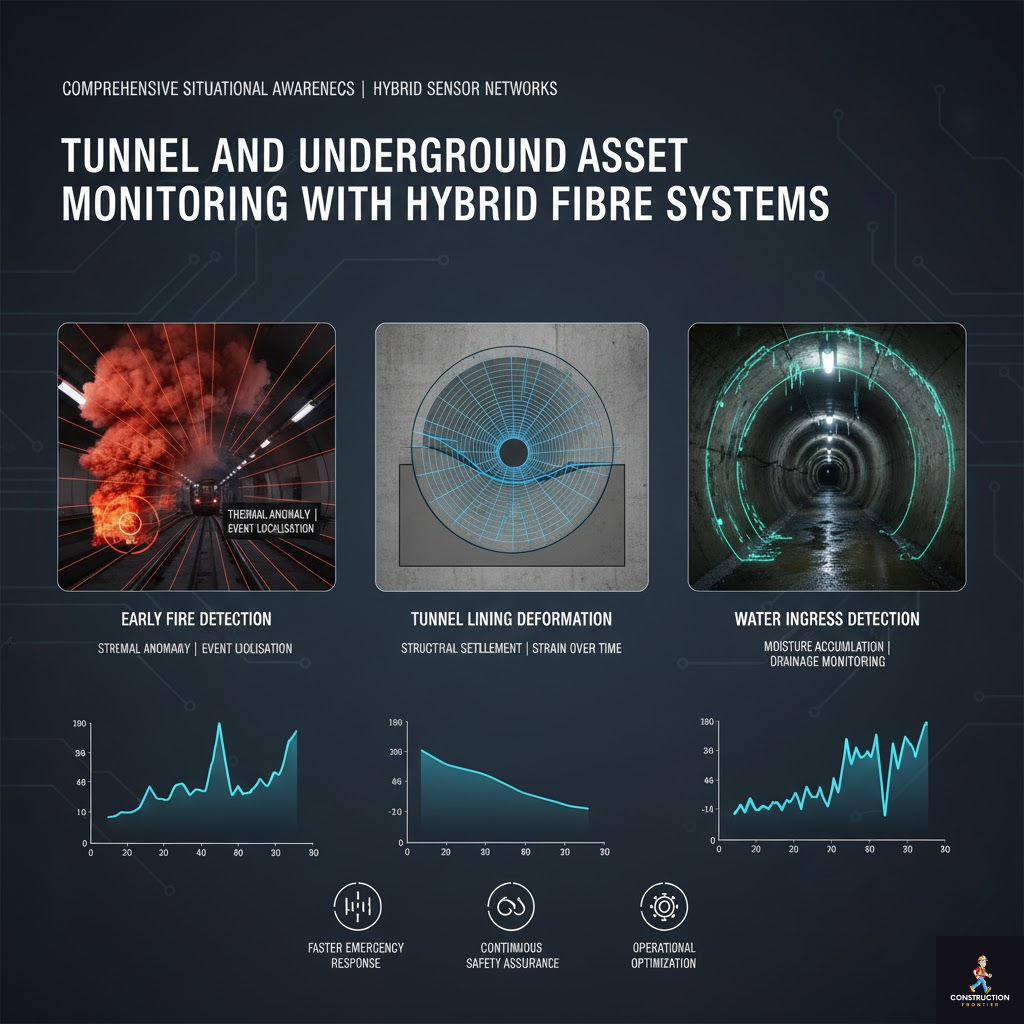

8. Tunnel and Underground Asset Monitoring With Hybrid Fibre Systems

Tunnels, subways, and underground utilities demand continuous, robust monitoring. Hybrid systems that combine DTS, DAS, and FBGs provide a layered view of thermal, acoustic, and strain behaviour for underground infrastructure.

Overview and how it works

A combination of distributed thermal monitoring and acoustic/strain sensing yields comprehensive situational awareness from fire detection to structural movement.

Practical applications

- Early fire detection and smoke tracking in metro tunnels.

- Monitoring tunnel linings for settlement and deformation due to external loads.

- Detecting water ingress in sewer and stormwater tunnels.

Benefits for maintenance teams

- Faster emergency response with precise localisation of events.

- Continuous safety assurance for busy underground networks.

- Data for operational optimisation of ventilation, drainage, and asset management.

Implementation notes

Underground environments are harsh: robust cable protection and redundant interrogation hardware are recommended for mission-critical systems.

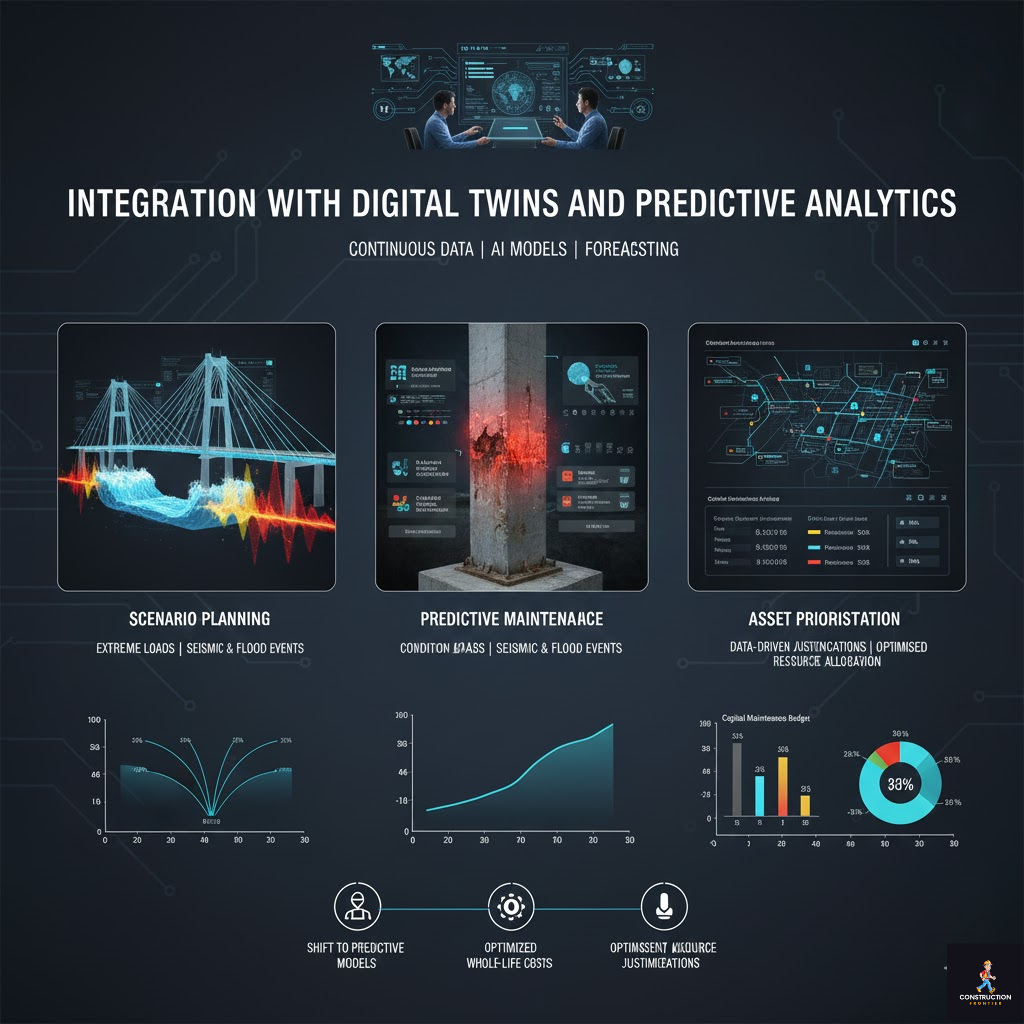

9. Integration With Digital Twins and Predictive Analytics

The power of fibre optic sensing in infrastructure maintenance multiplies when sensor streams feed into digital twins and machine-learning models. Continuous, high-resolution data enables physics-based models to predict future damage trajectories.

Overview and how it works

Sensor data pipelines feed cloud or edge analytics. Digital twins simulate structural behaviour, validate observations, and forecast risk scenarios.

Practical applications

- Scenario planning for extreme loads (floods, seismic events).

- Condition-based maintenance scheduling driven by predicted degradation.

- Asset prioritisation for capital maintenance budgets.

Benefits for maintenance teams

- Shift from calendar-based to predictive maintenance models.

- Optimised resource allocation and reduced whole-life costs.

- Transparent, data-driven justifications for interventions to funders and regulators.

Implementation notes

Integrating fibre optic monitoring systems with existing asset management requires standards, secure data architectures, and cross-disciplinary collaboration.

Further reading: 10 Ultimate Digital Twins Applications in Construction: Revolutionising Smart Building Performance

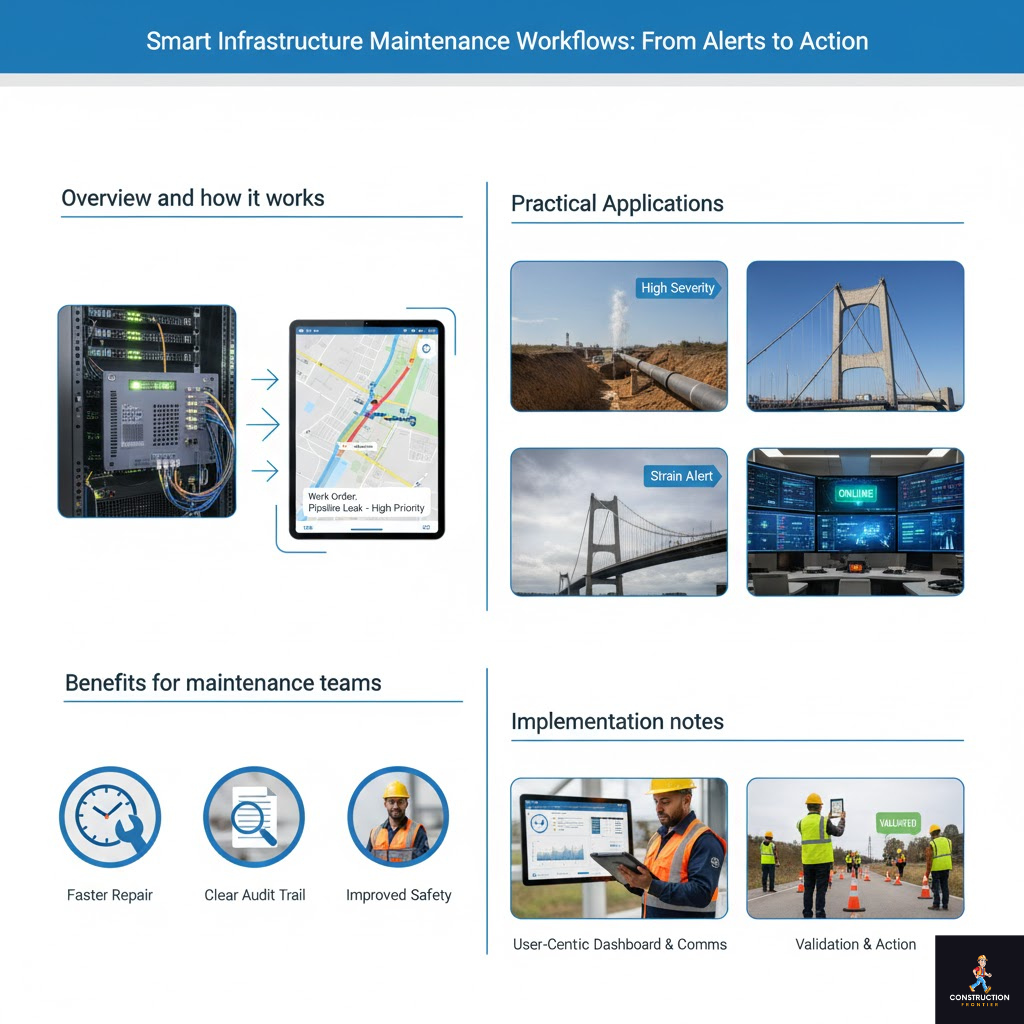

10. Smart Infrastructure Maintenance Workflows: From Alerts to Action

Beyond sensing, transforming maintenance requires workflows that convert raw optical fibre sensor data into field actions. Automated alerts, GIS visualisation, and mobile inspection workpacks ensure that a detected anomaly becomes a prioritised repair or validated non-issue.

Overview and how it works

Alert rules translate thresholds or anomaly signatures from distributed sensing into ranked work orders with geolocation, severity, and suggested diagnostics.

Practical applications

- Automated field crew mobilisation for pipeline leak zones.

- Risk-based inspection schedules for bridges flagged by strain trends.

- Integrating sensing outputs into utility control rooms for continuous operations.

Benefits for maintenance teams

- Faster mean-time-to-repair and reduced escalation costs.

- Clear audit trails linking sensor detection to remedial activity.

- Improved safety through targeted, evidence-based inspections.

Implementation notes

Effective workflows require user-centric dashboards, two-way communications with field teams, and validation steps to manage false positives.

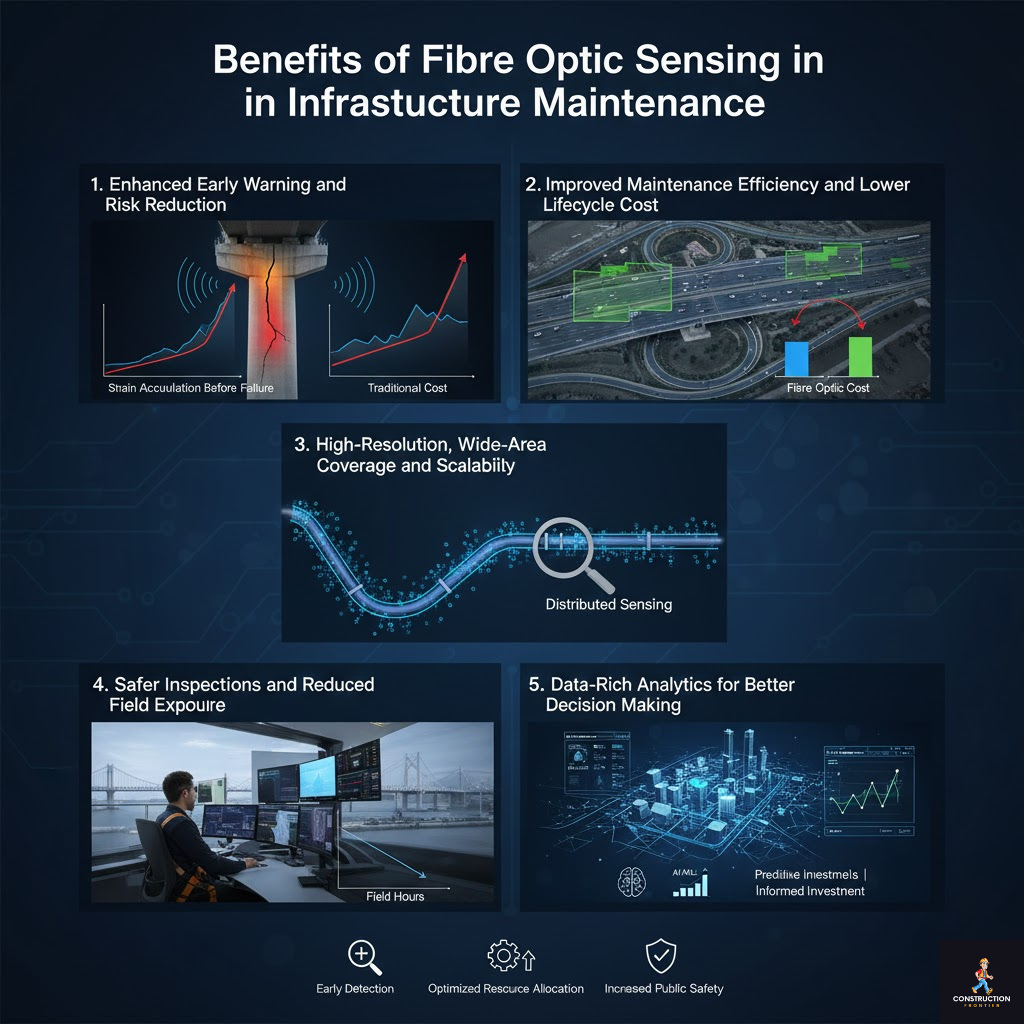

Benefits of Fibre Optic Sensing in Infrastructure Maintenance

Fibre optic sensing in infrastructure maintenance represents a fundamental shift from reactive inspection to continuous, intelligence-driven asset management. Unlike traditional inspection cycles that rely on periodic visual checks or point sensors, fibre optic monitoring systems deliver uninterrupted, distributed insight across entire structures. This allows asset owners to detect deterioration early, prioritise interventions accurately, and manage infrastructure with far greater confidence over its whole lifecycle.

1. Enhanced Early Warning and Risk Reduction

One of the most valuable advantages of fibre optic sensing in infrastructure maintenance is its ability to detect the earliest physical signs of distress long before visible damage appears. Distributed optical fibre sensors continuously measure strain, temperature, and acoustic signals along the full length of an asset. These subtle changes often precede cracking, settlement, fatigue, or structural instability by months or even years.

Early detection transforms risk management from a reactive response to a proactive strategy. Engineers gain time to plan targeted repairs, restrict loads, or adjust operations before minor defects escalate into failures. In high-consequence assets such as bridges, tunnels, dams, and pipelines, this early warning capability directly protects lives while reducing reputational and legal exposure for asset owners.

Key outcomes include:

- Identification of abnormal strain accumulation before structural cracking develops.

- Detection of thermal anomalies linked to leakage, insulation failure, or fire risk.

- Early acoustic signatures indicating impact, corrosion activity, or ground movement.

By providing actionable lead time, fibre optic sensing improves public safety while dramatically lowering the cost and disruption associated with emergency interventions.

2. Improved Maintenance Efficiency and Lower Lifecycle Cost

Traditional infrastructure maintenance often follows fixed inspection schedules that do not reflect the actual condition of assets. This leads to unnecessary repairs in some areas and late interventions in others. Fibre optic sensing in infrastructure maintenance enables a shift to condition-based and risk-based maintenance strategies.

Continuous monitoring data allows maintenance teams to focus resources only where deterioration is actively occurring. Instead of deploying crews across entire networks, operators can target specific locations with verified need. This approach reduces labour costs, minimises traffic closures, and improves asset availability.

Over time, the financial impact becomes substantial:

- Reduced frequency of manual inspections and site access costs.

- Avoidance of premature component replacement.

- Better prioritisation of limited maintenance budgets.

By extending the safe service life of structures through timely, data-driven interventions, fibre optic monitoring systems significantly reduce total lifecycle costs while improving operational efficiency.

3. High-Resolution, Wide-Area Coverage and Scalability

A defining strength of optical fibre sensors in construction and infrastructure is their ability to provide both high-resolution detail and long-range coverage using a single sensing medium. Depending on system architecture, one fibre can monitor thousands of discrete points or act as a continuous sensor over tens of kilometres.

This makes fibre optic sensing uniquely suited for linear and geographically dispersed assets such as bridges, highways, rail corridors, pipelines, and perimeter structures. Asset owners can deploy dense sensing in critical zones, such as expansion joints or fatigue-prone sections, while maintaining baseline coverage elsewhere.

Scalability is another significant advantage. Systems can be expanded incrementally by adding interrogators or extending fibre routes without redesigning the entire network. This modular approach supports gradual rollout from pilot projects to regional or national infrastructure monitoring programs, making advanced sensing technologies accessible even for budget-constrained agencies.

4. Safer Inspections and Reduced Field Exposure

Manual inspections often expose personnel to significant risks, including working at height, entering confined spaces, or operating near live traffic and active infrastructure. Fibre optic sensing in infrastructure maintenance reduces reliance on physical access by enabling remote, continuous observation of asset condition.

By replacing many routine site visits with sensor-based monitoring, organisations lower the frequency and duration of high-risk field activities. This not only improves worker safety but also reduces insurance costs, liability exposure, and operational disruptions caused by lane closures or service shutdowns.

Safer inspection outcomes include:

- Fewer inspectors are required in hazardous environments.

- Reduced the need for temporary access equipment such as scaffolding or rope systems.

- Improved compliance with occupational health and safety standards.

Remote monitoring allows engineers to focus field visits on confirmed issues rather than routine checks, improving both safety and productivity.

5. Data-Rich Analytics for Better Decision Making

Continuous data streams from fibre optic monitoring systems unlock new possibilities for advanced analytics and predictive maintenance. Instead of relying on isolated inspection reports, asset managers gain access to long-term performance trends and real-time condition indicators.

These datasets support the development of structural health monitoring technology that integrates machine learning, statistical modelling, and digital twins. Over time, systems learn the expected behaviour of each asset and flag deviations that indicate emerging problems.

Benefits of data-driven decision making include:

- More accurate forecasting of deterioration and remaining service life.

- Investment-grade reporting for regulators, insurers, and funding bodies.

- Transparent documentation that builds public trust in infrastructure safety.

By converting raw sensor data into actionable insight, fibre optic sensing strengthens strategic planning and capital investment decisions across infrastructure portfolios.

Further reading: Revolutionary Smart Sensors in Concrete: 10 Key Metrics They Monitor to Improve Structural Performance

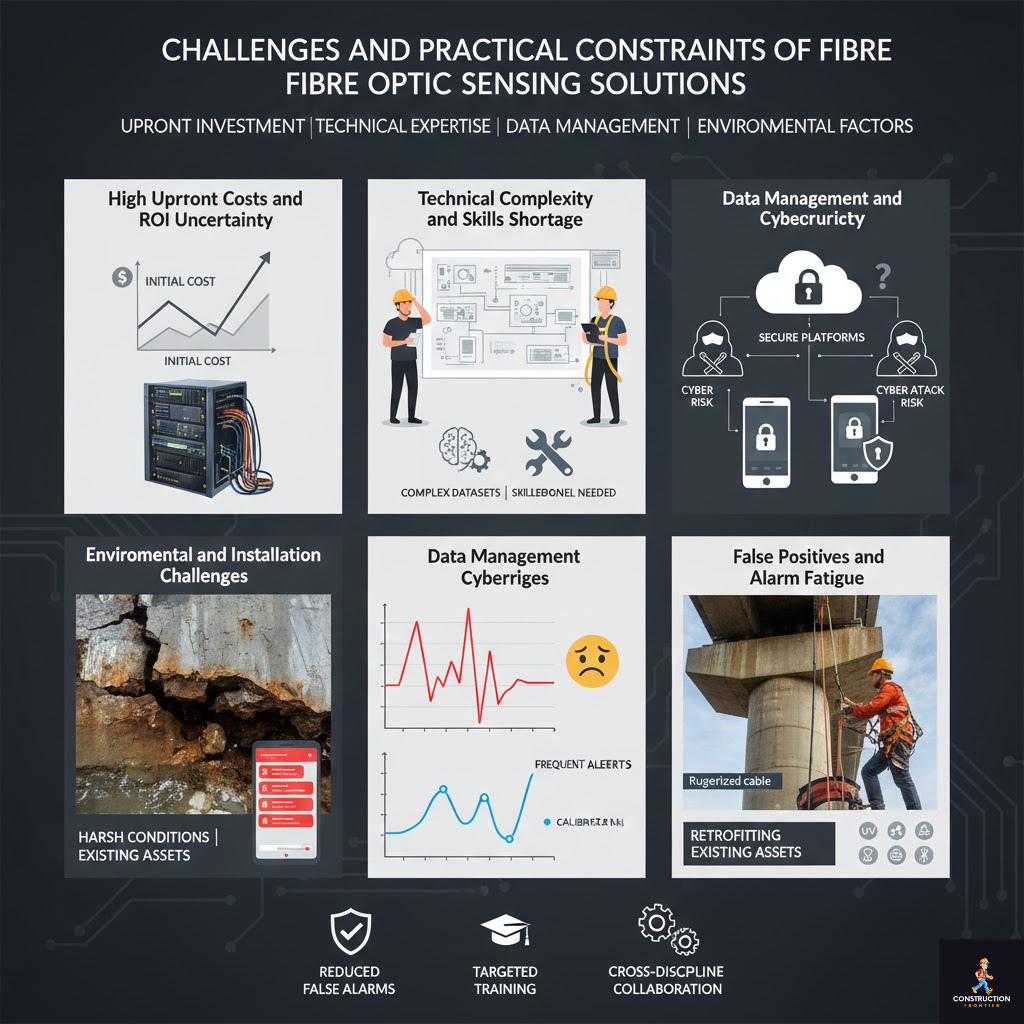

Challenges and Practical Constraints of Fibre Optic Sensing Solutions

Despite its advantages, fibre optic sensing in infrastructure maintenance is not without challenges. Successful deployment requires careful planning, technical expertise, and alignment between engineering, IT, and operations teams. Understanding these constraints helps asset owners adopt the technology realistically and sustainably.

1. High Upfront Costs and ROI Uncertainty

Initial deployment costs can be a barrier, particularly for large networks or retrofitting existing assets. Expenses may include ruggedised fibres, interrogators, communications infrastructure, integration software, and specialist installation services.

For organisations unfamiliar with advanced sensing technologies, quantifying return on investment (ROI) can be difficult at the outset. However, many successful programs begin with narrowly scoped pilots focused on high-risk or high-value assets. These pilots generate measurable benefits such as reduced emergency repairs, fewer unplanned outages, and extended asset life, which can then be used to justify wider rollout.

Phased procurement strategies, including modular systems or leased interrogators, also help spread capital expenditure and reduce financial risk.

2. Technical Complexity and Skills Shortage

Distributed fibre optic sensing systems generate complex datasets that require expertise in optics, signal processing, and civil engineering interpretation. Many infrastructure owners lack in-house capability to analyse and act on this data fully.

Addressing this challenge often involves partnering with experienced system integrators or adopting platforms that translate raw signals into intuitive alerts and dashboards. Investment in targeted training for engineering and maintenance staff further ensures that monitoring data is effectively used rather than underutilised.

As structural health monitoring technology matures, user interfaces and analytics tools are becoming more accessible, reducing dependence on niche expertise.

3. Data Management and Cybersecurity

Continuous monitoring generates large volumes of data, particularly for long-distance or high-resolution deployments. Without proper data governance, storage, and security frameworks, this information can become difficult to manage or vulnerable to misuse.

Best practice approaches include:

- Edge processing to filter data and transmit only meaningful events.

- Secure cloud platforms with encryption and role-based access.

- Clear data ownership and retention policies.

Robust cybersecurity measures are essential, especially for critical infrastructure, where monitoring systems may interface with operational control networks.

4. Environmental and Installation Challenges

Installing optical fibre sensors in construction and infrastructure environments can be complex, particularly in harsh conditions. Exposure to ultraviolet radiation, chemicals, vibration, or seismic activity requires careful selection of fibre type, jacketing, and protective routing.

Retrofitting existing structures presents additional constraints related to access, anchoring, and calibration. Successful projects account for these challenges during design by selecting appropriate installation methods and allowing time for baseline data collection before operational use.

5. False Positives and Alarm Fatigue

High sensitivity is both a strength and a challenge. Without proper calibration, fibre optic monitoring systems may generate frequent alerts that do not correspond to meaningful risk. Over time, this can lead to alarm fatigue and reduced trust in the system.

Effective mitigation strategies include combining multiple sensing modalities, building asset-specific event libraries, and applying machine learning models trained on local conditions. When alarms are reliable and actionable, teams respond faster and with greater confidence.

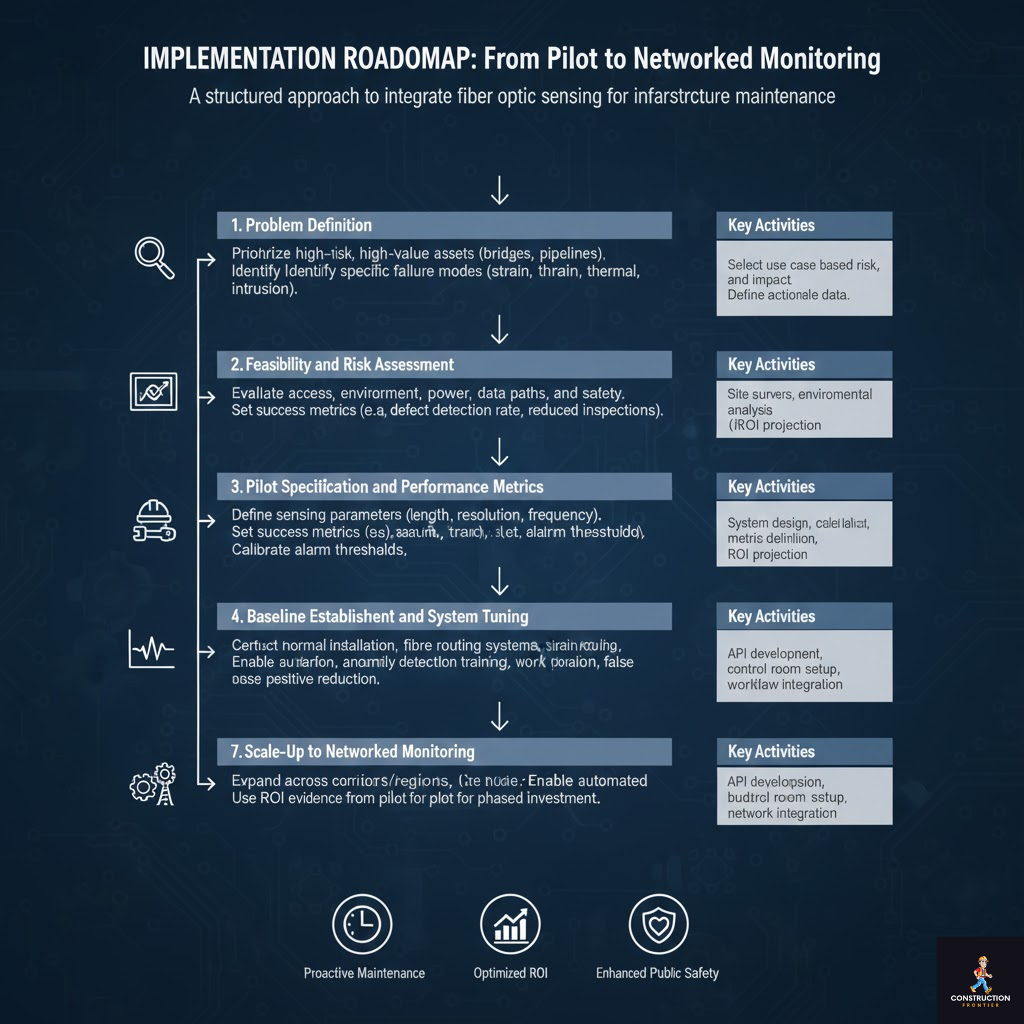

Implementation Roadmap. From Pilot to Networked Monitoring

A structured implementation roadmap is essential for successfully deploying fibre optic sensing in infrastructure maintenance. Without a phased approach, organisations risk underutilising advanced sensing technologies or failing to demonstrate return on investment. The roadmap below reflects best practice across infrastructure maintenance solutions, helping asset owners move confidently from small-scale trials to fully integrated monitoring networks.

1. Problem Definition: Selecting High-Value Use Cases

Every successful deployment begins with a clearly defined problem. Rather than attempting blanket monitoring, infrastructure owners should prioritise high-risk, high-impact assets such as fatigue-prone bridges, landslide-sensitive slopes, ageing pipelines, or heavily trafficked road sections. Identifying a specific failure mode, such as excessive strain, thermal stress, or third-party intrusion, ensures that optical fibre sensors in construction are configured to capture actionable data rather than generic signals.

2. Feasibility and Risk Assessment

Before installation, a detailed feasibility study evaluates physical access, environmental exposure, power availability, data transmission pathways, and safety constraints. This step is particularly critical for retrofitting fibre optic monitoring systems into existing infrastructure. Environmental conditions such as vibration, moisture, UV exposure, or chemical attack must be assessed to determine appropriate fibre jacketing, armouring, and installation methods. Early risk assessment reduces installation errors and long-term reliability issues.

3. Pilot Specification and Performance Metrics

A pilot should be technically precise and outcome-driven. Key parameters include sensing length, spatial resolution, sampling frequency, and data latency. Equally important are success metrics tied to infrastructure maintenance solutions, such as early defect detection rates, reduction in manual inspections, or avoidance of service disruptions. Well-defined pilots provide quantitative evidence of how fibre optic sensing improves infrastructure maintenance outcomes.

4. Installation and Commissioning

Installation quality directly affects data reliability. Certified installation teams should follow documented procedures, ensuring correct fibre routing, strain coupling, protection, and termination. As-built documentation, including fibre paths and sensor zones, becomes essential for long-term operation and troubleshooting. Commissioning includes signal validation, continuity testing, and baseline data capture to confirm system readiness.

5. Baseline Establishment and System Tuning

Once operational, the system must capture baseline behaviour under normal environmental and operational conditions. Seasonal temperature cycles, traffic patterns, and operational loads are recorded to establish reference signatures. Thresholds for alarms are then calibrated to distinguish genuine structural issues from benign variations. This tuning process is fundamental to reducing false positives in structural health monitoring technology.

6. Integration With Asset Management and SOPs

For fibre optic sensing in infrastructure maintenance to deliver value, data must flow into existing asset management systems, control rooms, and maintenance workflows. Integration enables automated alerts, prioritised work orders, and documented responses aligned with standard operating procedures. This step transforms sensing data into operational intelligence rather than isolated technical outputs.

7. Scale-Up to Networked Monitoring

Once pilots demonstrate value, organisations can scale incrementally. Modular interrogators, distributed architectures, and standardised data formats allow expansion across corridors, regions, or asset classes. ROI evidence from the pilot phase supports phased investment, enabling infrastructure owners to transition from reactive maintenance to network-wide predictive monitoring.

Cost-Benefit Snapshot: How Owners Justify Investment

Justifying investment in fibre optic sensing in infrastructure maintenance requires a clear understanding of both direct and indirect benefits. While initial capital costs may appear high, lifecycle analysis consistently shows strong economic justification for critical assets.

1. Reduced Unplanned Downtime

Continuous monitoring detects early warning signs before failures escalate into service disruptions. Preventing emergency closures, traffic diversions, or pipeline shutdowns saves direct repair costs while protecting public confidence and organisational reputation. For transport and utility operators, avoided downtime often delivers the most significant financial benefit.

2. Optimised Maintenance Spend

Fibre optic monitoring systems enable condition-based maintenance instead of routine or calendar-based interventions. Maintenance teams focus resources where deterioration is confirmed, reducing unnecessary inspections, materials waste, and labour costs. This targeted approach significantly improves efficiency across large infrastructure portfolios.

3. Extended Asset Life and Capital Deferral

By detecting issues early, owners can implement minor corrective actions that prevent accelerated degradation. Extending asset life delays major rehabilitation or replacement projects, freeing capital for other priorities. This benefit is particularly valuable for ageing bridges, tunnels, and buried infrastructure.

4. Regulatory and Insurance Advantages

Demonstrating continuous monitoring using advanced sensing technologies strengthens compliance with safety regulations and risk management frameworks. Insurers increasingly recognise fibre optic sensing as a risk-reduction measure, leading to lower premiums and improved coverage terms. Regulators also view continuous monitoring favourably during audits and approvals.

Across critical infrastructure assets, well-designed deployments commonly achieve payback within three to five years, even before accounting for societal and safety benefits.

Future Directions. Smarter, Cheaper, and More Integrated

The future of fibre optic sensing in infrastructure maintenance points toward broader adoption, lower costs, and deeper integration with digital ecosystems. As technology matures, sensing will shift from specialist deployments to standard practice.

Interrogator hardware is becoming more compact, energy-efficient, and affordable, reducing barriers for smaller infrastructure owners. Plug-and-play fibre solutions and simplified installation methods will further accelerate uptake across roads, bridges, railways, and utilities.

Edge-based analytics and artificial intelligence will increasingly process data closer to the asset, enabling faster event classification and reducing data transmission loads. This evolution supports real-time decision-making while lowering operational costs associated with large data volumes.

Standardisation of data formats, interfaces, and APIs will enable vendor-agnostic systems that integrate seamlessly with BIM platforms, digital twins, and smart city dashboards. As a result, fiber optic sensing will become a core layer within smart infrastructure maintenance using fiber optic sensing, supporting predictive resilience at city and national scales.

Conclusion. A Strategic Must for Critical Infrastructure

Fibre optic sensing in infrastructure maintenance represents a fundamental shift in how assets are protected, managed, and optimised. By delivering continuous, high-resolution insight across long distances and complex structures, fibre optic monitoring systems overcome the limitations of periodic inspections and manual surveys. The ability to detect subtle strain, temperature, and acoustic changes enables earlier intervention, safer operations, and more confident decision-making across infrastructure networks.

As infrastructure ages and performance demands increase, adopting advanced sensing technologies is no longer optional for high-risk assets. Organisations that start with focused pilots, build internal capability, and scale strategically position themselves for safer, more resilient, and more cost-effective asset stewardship. Fibre optic sensing is not simply a monitoring upgrade; it is a cornerstone of modern infrastructure maintenance solutions and a defining technology for the future of structural health monitoring.

Call to Action: Learn More and Deploy Smart Monitoring With Construction Frontier

Want to bring fibre optic sensing in infrastructure maintenance to your assets? Visit ConstructionFrontier.com for detailed implementation guides, vendor comparisons, case studies, and hands-on templates to plan your pilot project. Get practical checklists for procurement, installation, and analytics so you can move from sensing to smarter maintenance today.