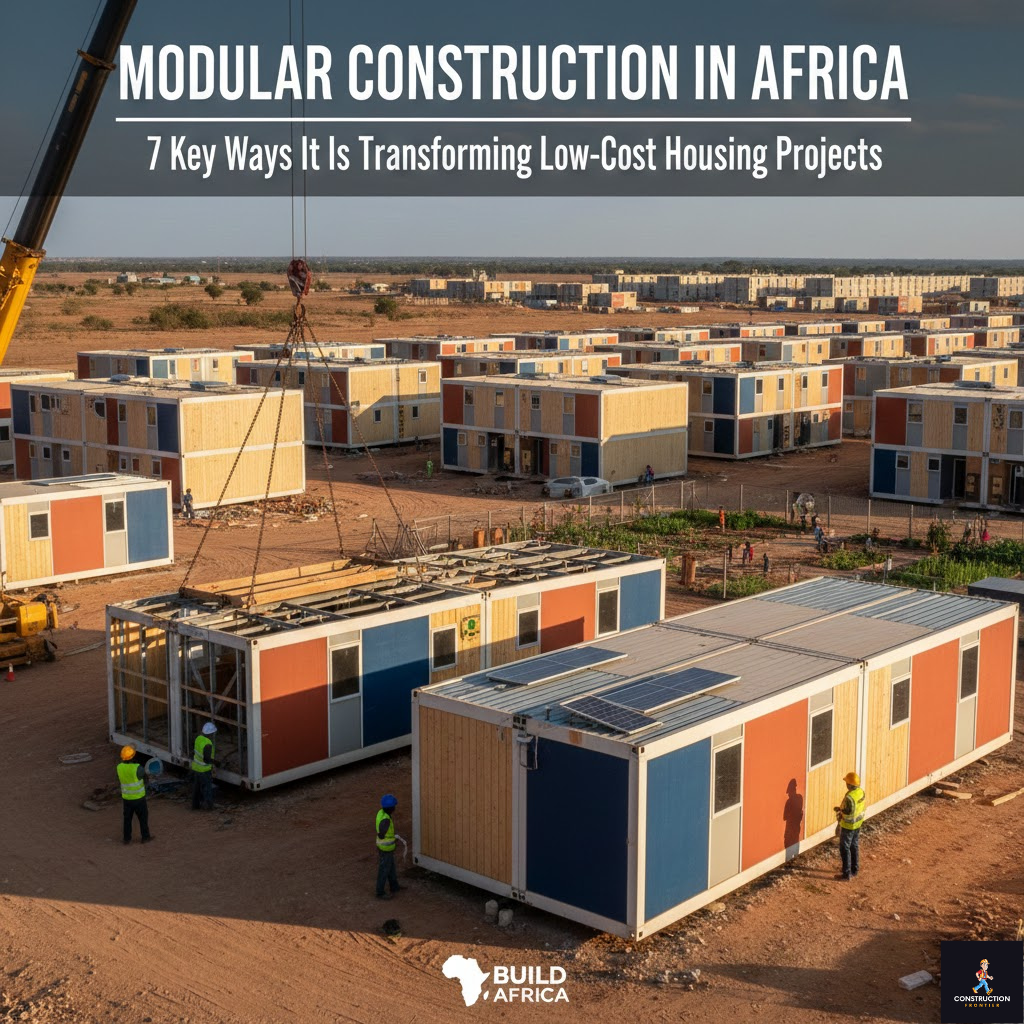

Modular Construction in Africa: 7 Key Ways It Is Transforming Low-Cost Housing Projects

Africa’s housing deficit is no longer just a policy issue. It is a construction challenge. Modular construction in Africa is emerging as one of the most practical ways to deliver affordable, scalable, and sustainable housing at a rapid pace.

Introduction: Africa’s Housing Crisis Meets Modular Construction Innovation

Africa is facing one of the fastest-growing housing crises in the world, driven by rapid urbanisation, population growth, and widening affordability gaps. From East to West and North to South Africa, millions of households are locked out of formal housing markets as construction costs rise faster than incomes.

According to UN-Habitat, Africa requires more than 4 million new housing units annually to close its current housing deficit. Traditional construction methods alone are struggling to keep pace. Labour shortages, rising material prices, inefficient procurement, and unpredictable site conditions all contribute to project delays.

This is where modular construction in Africa is changing the conversation. Before exploring its impact, it is essential to clearly define what modular construction is and why it is so significant for low-cost housing projects in Africa today.

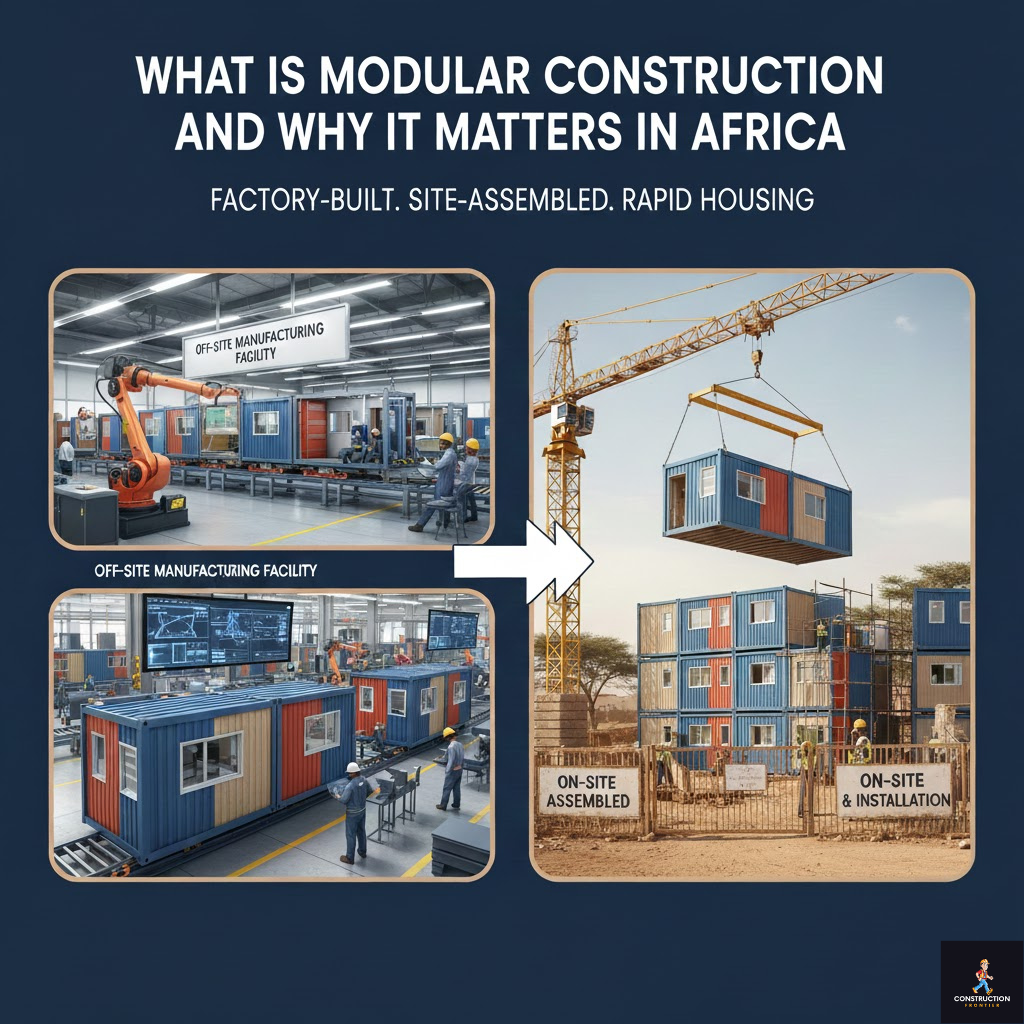

What Is Modular Construction and Why It Matters in Africa

Modular construction is a building method where housing units or components are manufactured off-site in controlled factory environments, then transported and assembled on-site. Unlike conventional construction, where most work occurs at the project location, modular housing shifts a significant portion of the construction process to factories.

How Modular Construction Differs from Traditional Building

Traditional building construction in Africa is heavily site-dependent. Weather disruptions, inconsistent labour availability, and material wastage are common challenges. Modular construction reverses this model by standardising production.

Key differences include:

- Parallel construction processes (site work and module fabrication happen simultaneously).

- Factory-controlled quality and precision.

- Reduced on-site labour demand.

- Predictable costs and timelines.

For Africa, where housing demand is urgent, and budgets are tight, these differences are not minor improvements. They are structural advantages.

Why Modular Construction Fits African Realities

Modular housing architecture aligns well with Africa’s construction environment because it addresses:

- Rapid urbanisation.

- Informal settlement growth.

- Limited skilled labour pools.

- Infrastructure delivery delays.

- Financing uncertainty.

As governments and developers in Africa seek affordable housing construction solutions, modular construction is increasingly viewed as a viable alternative rather than an experimental approach.

Further reading: New Technology to Cut Costs for Builders, Helping Boost Efficiency and Productivity

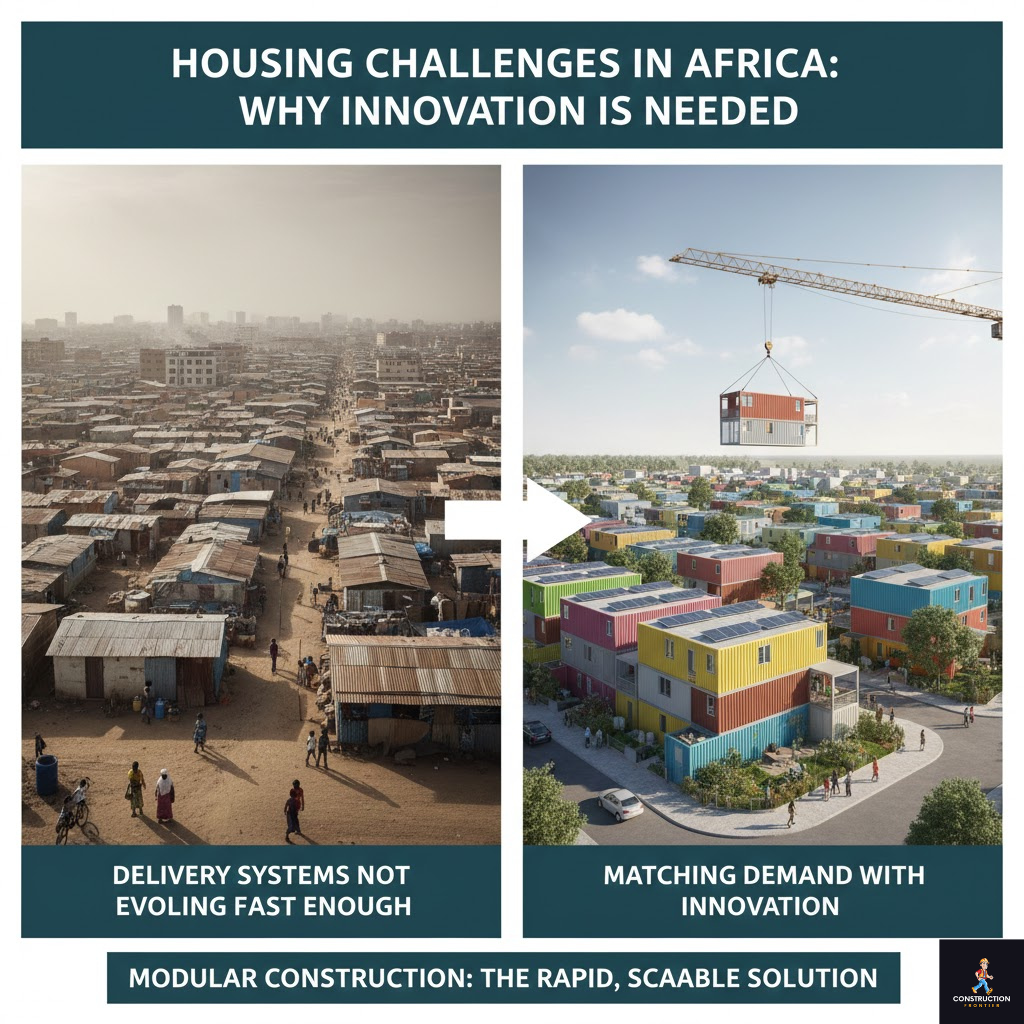

Housing Challenges in Africa: Why Innovation Is Needed

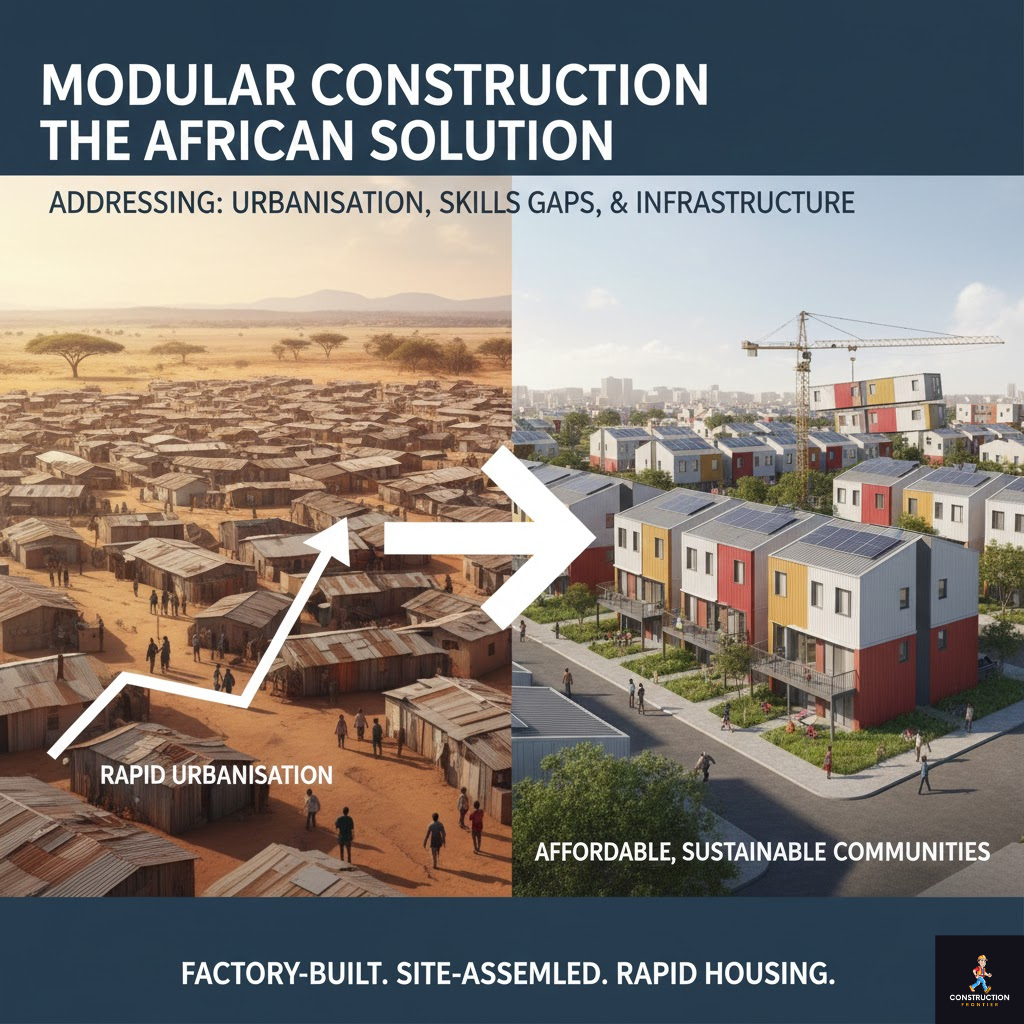

Africa’s affordable housing challenge is not just about numbers. It is about delivery systems that have not evolved fast enough to match demand.

The Scale of the Housing Gap

The World Bank estimates that sub-Saharan Africa alone faces a housing deficit exceeding 50 million units, with urban populations expected to double by 2050. Countries like Nigeria and Kenya add hundreds of thousands of new urban households every year, as seen in the Kenya National Affordable Housing Program.

Yet most low-cost housing projects in Africa face recurring obstacles:

- High construction costs.

- Long project timelines.

- Limited access to housing finance.

- Weak supply chains.

- Regulatory bottlenecks.

Why Traditional Construction Is Falling Short

Conventional building methods rely heavily on manual labour and on-site processes. This makes housing delivery vulnerable to delays, cost overruns, and quality inconsistencies.

In many African cities, these limitations have pushed low-income households into informal settlements, deepening social and infrastructure challenges. Modular construction offers a different path, one focused on speed, scale, and cost control.

Further reading: 65 Affordable Housing Projects in Kenya: Transforming Urban Living for All

Benefits of Modular Construction in Africa: Delivering High-Impact Outcomes for Low-Cost Housing

Modular construction in Africa isn’t just a trend; it’s a strategic solution directly addressing systemic challenges in low-cost housing projects. By shortening timelines, cutting costs, and improving quality, modular methods are delivering outcomes that traditional onsite construction often fails to achieve at scale. Below, each benefit is explained in context, accompanied by examples and clear relevance to modular affordable housing in Africa, modular housing architecture, and sustainable housing solutions in Africa.

1. Fast Delivery and Accelerated Housing Availability

One of the most apparent benefits of modular construction in Africa is the compression of project schedules. Traditional methods often require sequential activity site preparation, foundation, framing, roofing, utilities, and finishing, each of which depends on the last. In contrast, modular building components are manufactured off-site while groundworks happen simultaneously. This parallel workflow can reduce delivery times by up to 30–50% compared with conventional projects.

- Example: In Rwanda, Kigali’s pilot modular housing initiatives assembled pre-built wall panels and bathroom pods in weeks, not months, thereby accelerating delivery for low-income communities where the annual need runs into the tens of thousands. Urban policymakers note that reducing delivery time directly helps close the housing gap more quickly.

- Why it matters: According to the UN-Habitat’s 2024 annual report, for rapidly urbanising African cities, where millions move into urban centres each year, faster housing delivery significantly reduces the risk of expanding informal settlements and slum growth, while enabling quicker occupancy and social upliftment.

2. Cost Efficiency and Predictable Budgeting

Modular construction cost savings in Africa are rooted in controlled factory environments, bulk procurement, and reduced site waste. On-site job sites are notoriously inefficient: materials can degrade, theft can occur, and labour may idle due to weather delays or miscoordination. Off-site modular manufacturing minimises these inefficiencies.

- Direct savings: Less material waste, shorter construction durations, and lower labour hours reduce overall project budgets. Prefabricated housing solutions in Africa often cost 10–25% less per unit compared to traditional builds when volume production and process optimisation are scaled.

- Budget predictability: Standardised modules allow developers and government programmes to forecast costs confidently, improving access to financing from public budgets, blended finance vehicles, and impact investors.

The Stocktaking of the Housing Sector in Sub-Saharan Africa report indicates that financial clarity supports the affordable housing construction Africa needs, where unpredictable overruns have historically stalled critical projects.

3. Improved Quality and Construction Consistency

In factory conditions, quality control is systematic, repeatable, and less influenced by weather or labour variability. This is a defining benefit of modular housing architecture that elevates build quality across projects.

- Structural integrity: Controlled production environments ensure consistent standards for concrete curing, thermal insulation, and precision joinery, resulting in a stronger and more durable housing stock.

- Regional resilience: In climates characterised by heavy rains, high humidity, or intense heat, such as coastal West Africa or inland East Africa, modular units consistently maintain design performance with fewer defects than site-dependent construction.

- Maintenance benefits: Homes delivered with standardised components often have fewer early maintenance needs, reducing lifecycle costs for occupants and asset owners.

In South Africa and other markets, this quality consistency is increasingly recognised as a core advantage of modular projects.

4. Greater Sustainability and Environmental Performance

Modular construction embodies sustainable housing solutions in Africa, reducing waste, enabling resource optimisation, and supporting environmentally sound practices:

- Lower site waste: Factory precision ensures accurate material cutting and reuse, drastically reducing landfill debris compared to cut-and-frame sites.

- Energy performance: Integrated design methods facilitate the inclusion of energy-efficient insulation, solar integration, and ecological water systems, a key advantage for low-income neighbourhoods seeking lower utility burdens.

- Climate resilience: By simulating environmental exposure during factory production, modular housing often incorporates design features tailored to local climates, reducing long-term operational energy demand.

These sustainability benefits are directly tied to continental priorities for climate-smart infrastructure and green building technology frameworks, driven by policy incentives from UN-Habitat and other partners.

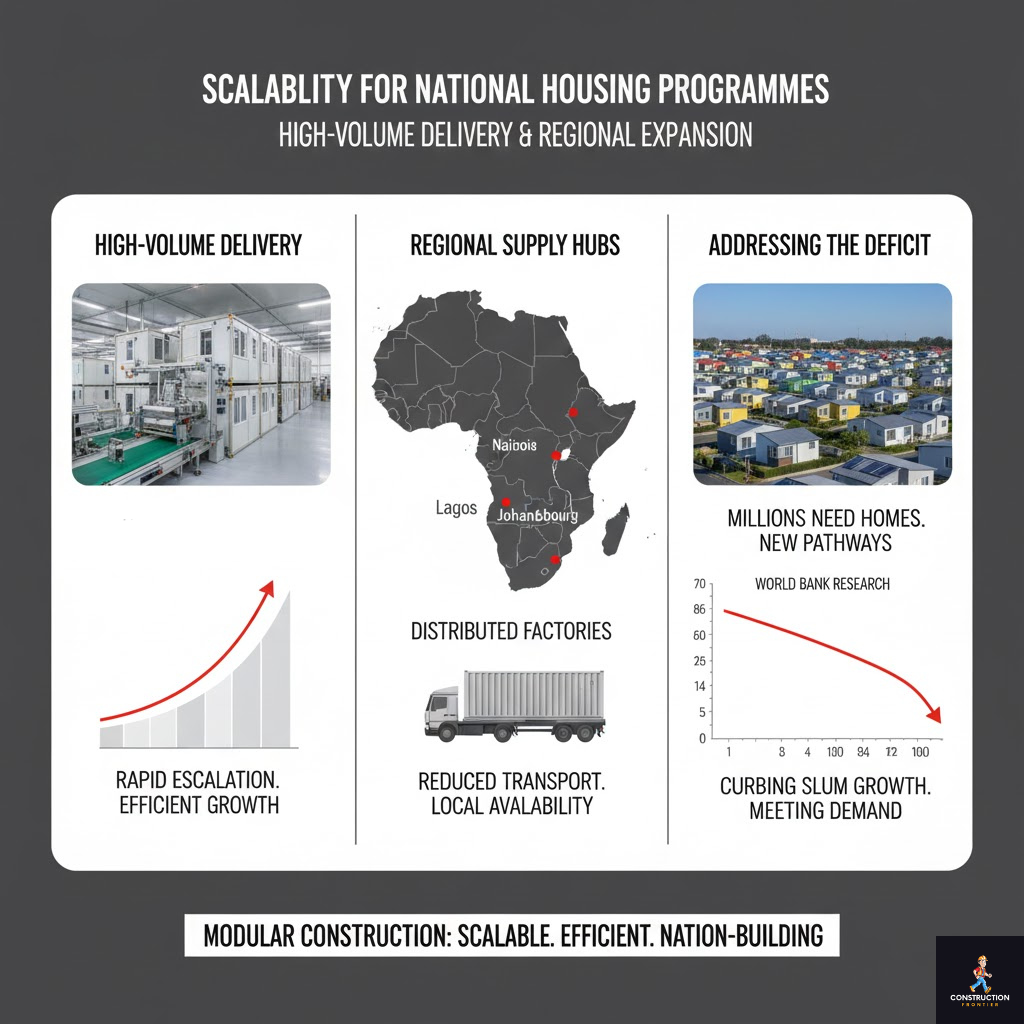

5. Scalability for National Housing Programmes

Once a modular manufacturing base is established, scaling up housing units becomes significantly easier than expanding conventional sites. Serial production lines enable:

- High-volume delivery: Standardised units can be repeated across neighbourhoods and regions without proportional increases in cost or labour demand.

- Regional supply hubs: Distributed modular factories in hubs like Lagos, Nairobi, and Johannesburg can service large regions, reducing transport costs and improving local availability of affordable units.

For countries like Nigeria, with tens of millions of housing deficits, this scalability is essential. According to World Bank sector research, the population of informal settlements in Sub-Saharan Africa is expected to grow significantly unless new delivery pathways emerge.

6. Local Job Creation Through Assembly and Manufacturing

Despite misconceptions, modular construction can increase local employment:

- Assembly jobs: Factory hubs employ technicians, assemblers, logistic teams, and quality inspectors, roles that build transferable skills.

- Local supply chains: Procuring materials locally stimulates adjacent industries, such as cement production, metalworking, and transportation services.

- Community empowerment: Local training initiatives, sometimes supported by organisations like the Housing Finance Foundation in Kenya, expand skilled labour pools, creating new opportunities in urban and peri-urban zones.

By creating modular manufacturing clusters, African economies can both address housing deficits and strengthen industrial capacity.

7. Better Financing and Investment Appeal

Modular methods reduce risk profiles for lenders by offering predictable costs, fixed delivery schedules, and measurable quality outcomes.

- Investor confidence: Banks and impact investors are more willing to allocate capital when projects have clearer risk management, which modular construction often provides.

- Donor and development support: Institutions such as the African Development Bank (AfDB) and Shelter Afrique are actively structuring funding mechanisms to unlock affordable housing finance, particularly where industrialised building methods are applied.

Challenges Facing Modular Construction in Africa

Even as modular construction advances affordable housing, several real-world obstacles remain. Understanding these challenges helps policymakers, developers, and financiers craft realistic deployment strategies.

1. High Upfront Costs and Value Chain Shifts

Establishing modular factories, logistics systems, and supply chains requires significant capital investment. These initial investments can be substantial:

- Factory infrastructure: including land, machinery, and tooling, requires upfront capital that mid-sized developers may find prohibitive.

- Transport costs: Moving large modules across long distances, especially in landlocked or poorly connected regions, can be expensive.

Mitigation: Phased rollouts and public-private partnerships can spread initial costs. Donor agencies, housing funds, and blended finance can also mitigate risk.

2. Skills Gaps and Technical Training Needs

Modular construction demands skills in precision manufacturing, digital design, supply chain management, and factory workflows, competencies that differ from traditional craft methods. Significant investment in training is needed.

Mitigation: Partnerships with vocational education systems and international modular firms, along with employer-led training centres, can build capacity.

3. Logistics and Regulatory Bottlenecks

In many African cities, infrastructure gaps, including poor road access, limited rail freight reliability, and cumbersome permitting processes for off-site units, slow the implementation of modular solutions.

Mitigation: Policy reform, digital permitting systems, and improved freight corridors will accelerate uptake.

4. Perceptions and Market Understanding

Public perception sometimes views modular housing as “temporary” or “low quality,” a misconception that stems from early-generation prefab homes, not modern modular solutions.

Mitigation: Awareness campaigns, demonstration projects, and success stories from early adopters help shift stakeholder beliefs.

Technical Comparison of Traditional and Modular Construction Approaches for Affordable Housing in Africa

| Technical Parameter | Traditional On-Site Construction (African Context) | Modular Construction in Africa |

| Typical Project Duration | 18–36 months depending on site conditions, labour availability, weather exposure, and sequencing delays. | 6–12 months due to parallel workflows (off-site manufacturing + on-site foundations). |

| Construction Methodology | Sequential, site-dependent activities with high exposure to weather and logistics disruptions. | Parallelised process combining factory production with site works. |

| Cost Predictability | Low to moderate. High risk of variations due to labour fluctuations, material price volatility, and delays. | High. Factory pricing, standardised components, and fixed production schedules improve cost certainty. |

| Labour Productivity | Variable: Productivity is affected by skill shortages, site conditions, and informal labour practices. | Higher and more consistent. Factory environments improve output per labour hour |

| Material Waste Generation | Typically, 10–20% material waste due to cutting errors, rework, theft, and site damage. | Typically, 2–5% waste through precision manufacturing and controlled material use. |

| Quality Control Mechanism | Relies on site supervision and inspections, often inconsistent across projects. | Centralised quality assurance in factory conditions with repeatable standards. |

| Structural and Dimensional Accuracy | Variable: Dependent workmanship and site tolerances. | High: CNC cutting, jigs, and controlled assembly ensure tight tolerances. |

| Scalability for Housing Programmes | Limited: Scaling requires proportional increases in labour, supervision, and site management | Strong: Once production lines are established, unit output can increase without linear cost growth |

| Environmental Performance | Higher embodied waste and energy inefficiencies during construction. | Lower embodied waste, easier integration of energy-efficient design and services. |

| Weather Sensitivity | High: Rain, heat, and humidity frequently cause delays in African climates. | Low: Majority of construction occurs in protected factory environments |

| Suitability for Mass Affordable Housing | Challenging due to time, cost overruns, and inconsistent quality | Highly suitable due to speed, repeatability, and predictable unit costs |

Case Studies in Africa: Modular Housing in Action

Across Africa, modular housing is proving to be a practical solution for the continent’s growing urban housing demand. From Rwanda’s rapid deployment initiatives in Kigali to Kenya’s use of prefabricated shipping containers for affordable urban commercial facilities, and South Africa’s energy-efficient township upgrades to Nigeria’s large-scale pilot projects in Lagos, modular construction is helping governments and developers deliver quality housing more quickly and cost-effectively. These case studies illustrate how policy support, innovative building methods, and public-private collaboration are shaping the future of housing in Africa.

1. Rwanda: Kigali’s Rapid Housing Deployment

Rwanda’s urbanisation and housing strategy illustrates both the urgent demand for homes and how innovation, including modular approaches, can play a part in addressing it.

Housing demand and policy context

- Kigali’s rapid growth means that Rwanda faces a projected need for 5.5 million dwellings by 2050 to meet urban demand. To achieve this, the Rwandan government is pursuing ambitious affordable housing targets to build roughly 150,000 new homes annually.

- In 2025, Rwanda launched the national urbanisation policy, which officially plans to emphasise structured urbanisation, modern building permits, and streamlined systems to accelerate development.

Role of prefab/modular elements

- While Rwanda’s largest housing project, Vision City, uses traditional development methods to deliver thousands of units at scale, modular and prefabricated components are gaining attention as potential tools to boost delivery speed and quality.

- Modular systems, particularly steel-framed or panelised units, according to Karmod Modular Building Solutions, are noted for their rapid installation and cost efficiency, which are essential features for low-income social housing and urban densification.

- Large‑scale systematisation of modular housing is still in its early stages. Still, the country’s housing policies and urbanisation plans create a policy environment that is supportive of innovation and partnerships across the public and private sectors.

Takeaway: Rwanda’s case demonstrates that while traditional significant developments, such as Vision City, currently dominate the delivery landscape, modular and prefabricated construction are emerging enablers of faster, quality-controlled housing that aligns with national goals.

2. Kenya: Affordable Urban Housing with Prefabricated Panels

Kenya’s housing deficit, particularly in urban areas such as Nairobi and Mombasa, has made modular and prefabricated methods increasingly relevant.

Housing gap and urbanisation pressures

- Ethical Business Africa notes that Kenya’s annual housing need is estimated at around 200,000 units, yet conventional construction delivers far fewer homes, driving a sustained gap.

- Urban homeownership remains low, at roughly 21.3%, reflecting both cost barriers and slow delivery.

Efficiency and technology in practice

- Prefabricated systems, including expanded polystyrene (EPS) panels and precast concrete components, can significantly reduce on‑site labour, waste, and timeline risks, compared with traditional site builds.

- Academic research in the Nairobi Metropolitan Area has found that precast systems are the most cost-efficient prefabricated solution, at approximately KES 25,413/m², compared to other prefabricated formats. It notes that modular methods can improve predictability and affordability.

Policy and uptake challenges

- Regulatory fragmentation across Kenya’s counties with varied building codes hinders the adoption of standardised housing modules, despite their technical advantages.

- Sector experts argue that without clear policy direction and incentives, modular housing will struggle to scale despite technical feasibility.

Takeaway: Kenya is increasingly embracing prefabricated and modular construction in both the public and private sectors, but realising its full potential requires supportive regulation, financing tools, and coordinated roll‑out strategies.

3. South Africa: Sustainable Modular Housing for Townships

South Africa demonstrates that modular and prefabricated construction is not just a concept, but a part of an expanding market that addresses diverse housing needs, ranging from affordable homes to energy-efficient dwellings.

Market growth and delivery models

- Prefabricated buildings accounted for over half (58.2 %) of South Africa’s prefabricated buildings market in 2024, with residential applications capturing 51% of the market share.

- Modular solutions and panelised systems are projected for continued growth, supported by robust industry standards and certification pathways, such as Agrément certification, which can drastically shorten approval times.

Affordable housing and innovation

- Modular housing firms in South Africa are deploying insulated panel systems and steel frames that can be assembled rapidly, often within weeks rather than months, and tailored for climate resilience. Container Consumables

- The sector’s expansion is driven by both market demand (e.g., RDP-style affordable housing) and growing private interest in quicker, lower-cost alternatives to traditional building methods.

Social impact in township upgrades

- Modular housing technologies are increasingly seen as solutions for township housing upgrades, offering improved insulation, durability, and construction speed compared with informal or incrementally built structures.

Takeaway: South Africa’s modular housing market is one of the most developed in Africa, showcasing how policy support, standardised certification, and private innovation can drive broader adoption and improve living standards.

4. Nigeria: Lagos and the Challenge of Scale

Nigeria’s massive housing demand, particularly in megacities like Lagos, presents both an opportunity and a challenge for modular construction in terms of scalability.

Market dynamics and scale of need

- Mordor Intelligence notes that Nigeria accounted for nearly 30 % of Africa’s prefabricated housing construction market revenue in 2024, reflecting its vast housing deficit and urban growth pressures.

- That deficit spans millions of units nationwide, intensifying the need for scalable and cost-effective delivery models.

Modular housing approaches

- Advanced prefabricated housing projects, including those utilising concrete and steel modular components, are emerging to meet demand, often offering cost reductions and faster build times compared to traditional brick-and-mortar methods.

- Nigeria’s modular housing development encompasses both standalone estate projects and community-oriented initiatives that integrate modular systems with local building requirements.

Policy and financing constraints

- Despite its potential, modular construction faces barriers such as low mortgage penetration, financing costs, and supply-chain challenges that restrict its scale and affordability.

- Pilot projects and PPPs are shaping policy discussions, aiming to unlock modular construction at scale — though progress is still evolving.

Takeaway: Nigeria exemplifies how modular housing can contribute to large-scale supply solutions in high-demand, high-density contexts, but scaling these solutions requires innovative financing and policy alignment.

Overall Context: Africa’s Prefabricated Housing Market

A recent industry analysis by Mordor Intelligence forecasts that Africa’s prefabricated housing market will reach US $13.5 billion in 2025 and grow at a ~10.3 % CAGR through 2030, with modular homes representing the fastest‑growing segment.

Key trends driving this growth include:

- Rapid urbanisation is increasing demand for faster, standardised housing solutions.

- Government affordable housing programmes and Public-Private Partnerships (PPPs) are opening pipelines for prefab deployments.

- Modular systems offer predictable quality, shorter timelines, and lower waste compared with traditional construction.

Implementation Roadmap: From Pilot to Pan-African Scale

Modular construction in Africa requires a structured, phased implementation to ensure sustainable growth. Below is a step-by-step deployment framework suited for governments, developers, and financiers:

1. Strategic Use-Case Selection

Identify high-impact housing corridors, such as urban peripheries in Lagos, Nairobi slum upgrading zones, or township expansions in South Africa, where modular solutions can help reduce delays and costs.

2. Feasibility and Risk Assessment

Evaluate:

- Land availability and zoning regulations.

- Factory location potential.

- Transport and logistics networks.

- Financial models and funding sources.

3. Pilot Design and Specifications

Define modular unit types (e.g., 2-bedroom, 3-bedroom), performance standards (thermal, seismic, moisture), and success metrics (cost/unit, delivery time, occupant satisfaction).

4. Manufacturing Setup

Set up or partner with modular factories, ideally within regional hubs, to reduce transport costs and encourage industrial localisation.

5. On-Site Installation and Commissioning

Coordinate siteworks in parallel with module production and ensure quality assurance through third-party inspection.

6. Monitoring and Evaluation

Utilise real-time data and regular reviews to optimise processes, from factory efficiency to on-site assembly sequencing.

7. Scale-Up and Policy Integration

Use pilot outcomes to build investment cases for larger programmes, inform policy frameworks, and mainstream modular practices in national housing strategies.

Future of Modular Construction in Africa

The path ahead for modular construction in Africa points toward deeper integration, localisation, and technological enhancement.

1. Digitisation and Smart Manufacturing

Digital design tools, AI-assisted scheduling, and factory automation will increase accuracy and reduce costs, advancing modular housing architecture across Africa’s diverse climatic regions.

2. Policy Enablement and Financial Innovation

Government incentives, tax breaks, land policy reforms, and dedicated affordable housing funds will accelerate the adoption of these initiatives. Collaboration between organisations like the African Development Bank, Shelter Afrique, and national housing agencies will unlock scalable investment flows.

3. Workforce Development and Industrial Growth

As modular systems become mainstream, skilled training networks, from vocational schools to university programmes, will support resilient construction labour markets capable of servicing both local and export-oriented projects.

Further reading: Innovative Technology in Modern Construction Projects

Conclusion: Modular Construction as a Backbone of Africa’s Affordable Housing Future

Modular construction in Africa represents more than an alternative building method; it is a catalyst for transformative affordable housing outcomes. By compressing delivery times, enhancing quality, reducing cost uncertainty, and unlocking financing opportunities, modular approaches are helping bridge the continent’s enormous housing gap. With rapid urbanisation continuing and demand for millions of new units annually, modular solutions are no longer optional but essential to deliver low-cost housing projects in Africa at scale.

As policy frameworks evolve, industrial clusters expand, and technical training strengthens, modular construction will become an integrated feature of national housing strategies. Collaboration between governments, development banks, private developers, and local communities will determine how deeply and sustainably modular housing is embedded into Africa’s built environment. The future is modular, and for millions of Africans seeking secure, affordable homes, it promises real, measurable progress.

Call to Action: Build Smarter Housing in Africa

Africa’s housing future depends on smarter construction choices. Subscribe to ConstructionFrontier.com for expert insights on affordable housing, modular construction, and infrastructure innovation shaping the continent.