IoT in Infrastructure: 5 Proven Smart Ways It Enables Predictive Maintenance

IoT in infrastructure is transforming maintenance from reactive repairs to predictive, data-driven asset management, improving reliability, safety, and lifecycle performance of public assets.

Introduction: Why Predictive Maintenance Matters for Infrastructure

Infrastructure is the foundation of modern society. Roads enable trade, bridges support mobility, water systems protect public health, and energy networks power economies. Yet across the world, infrastructure assets are ageing faster than they are being renewed. Many were designed decades ago for lower traffic volumes, milder environmental conditions, and shorter service lives.

Traditionally, infrastructure maintenance has been reactive or calendar-based. Assets are repaired after failure or serviced at fixed intervals regardless of their actual condition. This approach leads to sudden breakdowns, safety incidents, service disruptions, and escalating costs. Emergency repairs are not only expensive but also socially disruptive, especially in transport and utility networks.

At the same time, governments and asset owners face budget constraints, rapid urbanisation, climate-related stress, and rising public expectations. Maintaining infrastructure efficiently has become a strategic priority rather than an operational afterthought.

This is where IoT in infrastructure is reshaping the maintenance landscape. By embedding sensors, connectivity, and analytics into physical assets, infrastructure managers can continuously monitor conditions, detect early signs of deterioration, and intervene before failures occur. These capabilities complement innovations in AI in civil engineering, which are already transforming how engineers design, manage, and maintain public assets.

This article explains five smart ways IoT in infrastructure enables predictive maintenance, shifting infrastructure management from a reactive to a resilient and future-ready approach.

What Is IoT in Infrastructure?

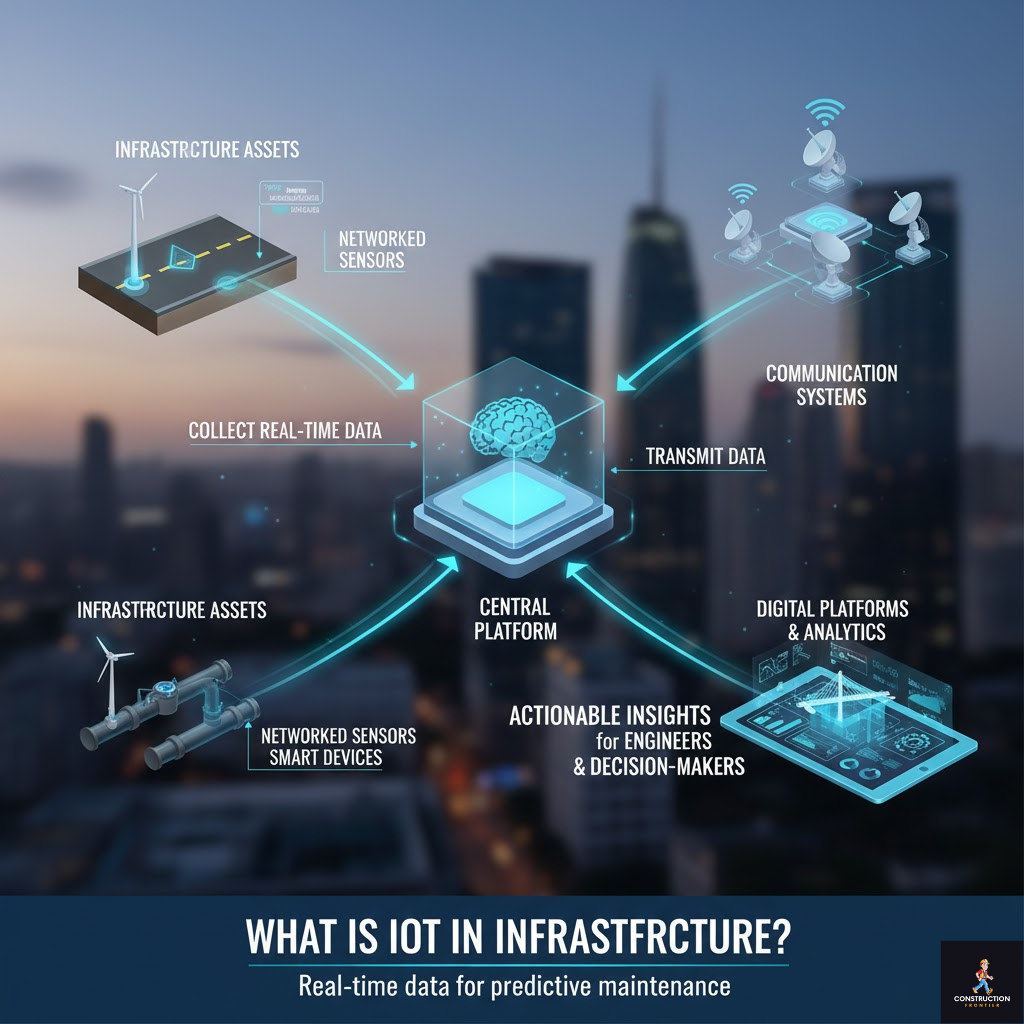

To understand its role in predictive maintenance, it is essential to clearly define the Internet of Things (IoT) in the context of infrastructure and its application to physical assets.

“IoT in infrastructure refers to the integration of networked sensors, smart devices, communication systems, and digital platforms within infrastructure assets. These systems collect real-time data on asset condition and performance, transmit it to central platforms, and convert it into actionable insights for engineers and decision-makers.”

Instead of relying solely on manual inspections and historical records, IoT in infrastructure provides continuous, objective, and location-specific data. Infrastructure assets become intelligent systems capable of reporting their performance, degradation, and when intervention is required.

Infrastructure Assets Commonly Using IoT

IoT in infrastructure is increasingly deployed across a wide range of asset types, including:

- Roads, highways, pavements, and intersections.

- Bridges, tunnels, viaducts, and elevated structures.

- Railways, metro systems, signalling equipment, and rolling stock.

- Water supply pipelines, pumping stations, and wastewater networks.

- Power generation plants, transmission lines, substations, and distribution grids.

Each of these assets produces valuable data related to structural integrity, operational efficiency, and environmental exposure.

How IoT Systems Work in Infrastructure

IoT in infrastructure operates as an integrated, multi-layered digital ecosystem designed to transform raw physical measurements into actionable maintenance intelligence. Rather than functioning as isolated technologies, IoT systems rely on the seamless interaction of sensing, communication, data processing, and analytics layers. Each layer plays a distinct role in enabling predictive and condition-based maintenance across complex infrastructure networks.

1. Sensors: The Physical Interface Between Assets and Data

Sensors form the foundation of IoT-enabled infrastructure systems. They are embedded within or attached to physical assets to continuously capture performance and environmental data that would otherwise require manual inspection or remain entirely invisible.

In transport infrastructure, sensors measure parameters such as strain, displacement, vibration frequency, and acceleration to assess structural behaviour in bridges, flyovers, and elevated roadways. Changes in vibration signatures can indicate fatigue damage, joint loosening, or bearing deterioration long before visible cracks appear.

In water infrastructure, pressure sensors, flow meters, acoustic sensors, and corrosion probes are deployed across pipelines and pumping stations. These sensors detect pressure transients, abnormal flow patterns, and chemical conditions that signal leaks, pipe wall thinning, or internal corrosion. For pumps and motors, vibration and temperature sensors monitor bearing wear, cavitation risk, and motor efficiency loss.

Energy infrastructure relies on highly specialised sensors, including thermal sensors, dissolved gas analysers, partial discharge sensors, and load monitoring devices. These capture critical indicators of transformer insulation health, conductor overheating, and electrical stress, which are key predictors of failure.

Modern sensor systems are increasingly:

- Low-power to support long-term deployment.

- Ruggedised to withstand harsh environmental conditions.

- Self-calibrating to reduce maintenance burden.

- Capable of edge processing to pre-filter data.

By converting physical asset behaviour into continuous digital signals, sensors enable infrastructure owners to move beyond periodic inspections to real-time condition awareness.

Further reading: 10 Remarkable Solutions of Fibre Optic Sensing in Infrastructure Maintenance: Enhancing Structural Safety

2. Connectivity: Transmitting Data Reliably and Securely

Connectivity is the backbone that allows sensor data to move from the field to central systems where it can be analysed and acted upon. The choice of communication technology is driven by factors such as asset location, data volume, latency requirements, power availability, and environmental constraints.

Urban infrastructure often relies on cellular networks and fibre-optic backbones, which support high data rates and low latency. These networks are well-suited for applications such as traffic signal monitoring, CCTV integration, and substation telemetry.

For distributed or remote infrastructure assets, low-power wide-area networks (LPWANs) such as LoRaWAN and NB-IoT are commonly used. These technologies enable long-range communication with minimal power consumption, making them ideal for pipeline monitoring, remote pumping stations, and rural water networks.

In highly remote or offshore environments, satellite communication provides essential coverage where terrestrial networks are unavailable. While more expensive, satellite connectivity ensures continuous data flow for critical infrastructure assets such as transmission corridors or isolated energy facilities.

Modern IoT infrastructure is increasingly adopting hybrid connectivity architectures, which combine multiple communication technologies to ensure redundancy and resilience. Edge gateways aggregate sensor data locally, perform initial validation, and transmit only relevant information, reducing bandwidth demand and improving system reliability.

3. Data Platforms: From Raw Signals to Structured Asset Intelligence

IoT data platforms act as the central nervous system of IoT-enabled infrastructure. They receive, store, process, and integrate data from thousands or even millions of sensors distributed across infrastructure networks.

At this layer, raw sensor data is:

- Time-stamped and geo-referenced.

- Cleaned to remove noise and anomalies.

- Normalised for consistency across asset types.

- Integrated with existing asset registers and maintenance records.

Advanced platforms connect IoT data with enterprise asset management systems, GIS platforms, and BIM models, creating a unified digital representation of infrastructure assets. This integration enables engineers to view sensor data in spatial context and relate performance trends to asset age, design specifications, and maintenance history.

Scalability is a critical requirement. Infrastructure data platforms must handle continuous data streams over decades while maintaining performance, security, and compliance. Cloud-based architectures are increasingly used due to their flexibility; however, hybrid cloud-edge models are more common for sensitive or latency-critical applications.

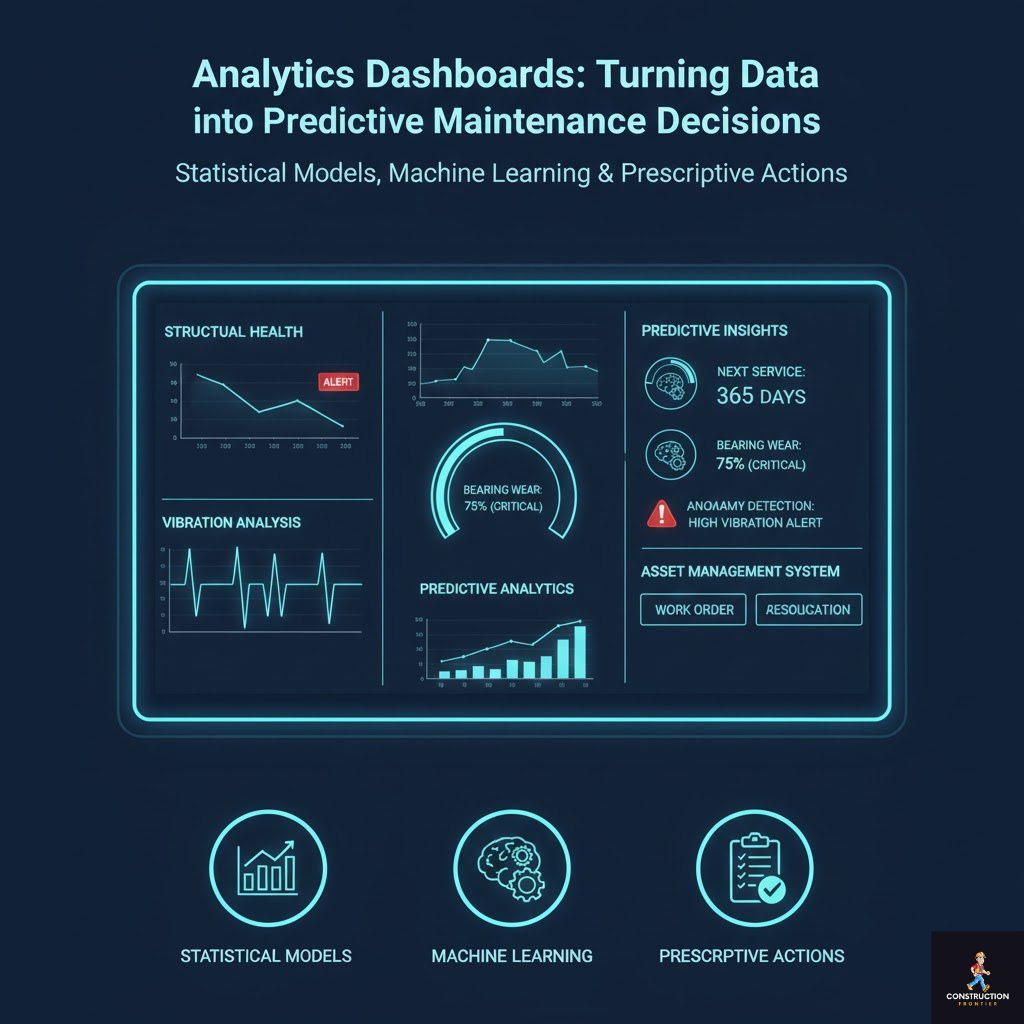

4. Analytics Dashboards: Turning Data into Predictive Maintenance Decisions

Analytics dashboards are where IoT data delivers tangible operational value. Rather than simply displaying raw measurements, advanced dashboards apply statistical models, rule-based logic, and machine learning algorithms to interpret asset behaviour and predict future performance.

These systems identify patterns such as:

- Gradual performance degradation.

- Sudden abnormal events.

- Correlations between environmental conditions and asset stress.

- Early indicators of component failure.

Predictive models estimate remaining useful life for critical components and recommend optimal maintenance windows based on risk, cost, and operational impact. Alerts are prioritised according to severity, ensuring that maintenance teams focus on the most critical issues first.

Well-designed dashboards present information in role-specific formats:

- Engineers view technical diagnostics and trend analyses.

- Asset managers see risk profiles and maintenance priorities.

- Executives access performance indicators and consider the associated cost implications.

By embedding analytics into daily decision-making, IoT systems shift infrastructure maintenance from reactive responses to proactive, risk-informed strategies.

Integrated System Impact

When these four layers operate together, IoT in infrastructure enables continuous asset awareness, early fault detection, and data-driven maintenance planning. The result is infrastructure that is safer, more reliable, and more cost-efficient over its lifecycle.

Rather than replacing engineering judgment, IoT systems enhance it by providing high-quality, real-time information that supports better decisions. This integrated approach forms the technical foundation of smart infrastructure monitoring and digital infrastructure maintenance, positioning asset owners to meet the demands of ageing systems, urban growth, and climate stress.

Understanding Predictive Maintenance in Infrastructure

Predictive maintenance represents a significant departure from traditional maintenance philosophies. It focuses on anticipating failures rather than responding to them.

Predictive maintenance uses real-time and historical condition data, combined with analytical models, to estimate when an asset is likely to fail or fall below acceptable performance levels. Maintenance is then carried out only when data indicates it is necessary.

Predictive vs Traditional Maintenance Approaches

- Reactive maintenance addresses failures after they occur, often resulting in unplanned downtime, safety risks, and high repair costs.

- Preventive maintenance follows fixed schedules, which can lead to unnecessary work or missed deterioration between inspections.

- Predictive maintenance intervenes at the optimal time, based on the actual condition and performance trends of the asset.

For public infrastructure, predictive maintenance is especially critical. Failures affect large populations, disrupt essential services, and create economic and political consequences. IoT in infrastructure provides the continuous data streams necessary to make predictive maintenance of infrastructure reliable, scalable, and cost-effective.

Further reading: Drones in Construction Site Inspections: 10 Innovations Improving Safety and Accuracy

5 Smart Ways IoT Enables Predictive Maintenance

IoT in infrastructure enables predictive maintenance through several interconnected mechanisms. Each of the five approaches outlined below plays a crucial role in enhancing asset reliability and lifecycle performance.

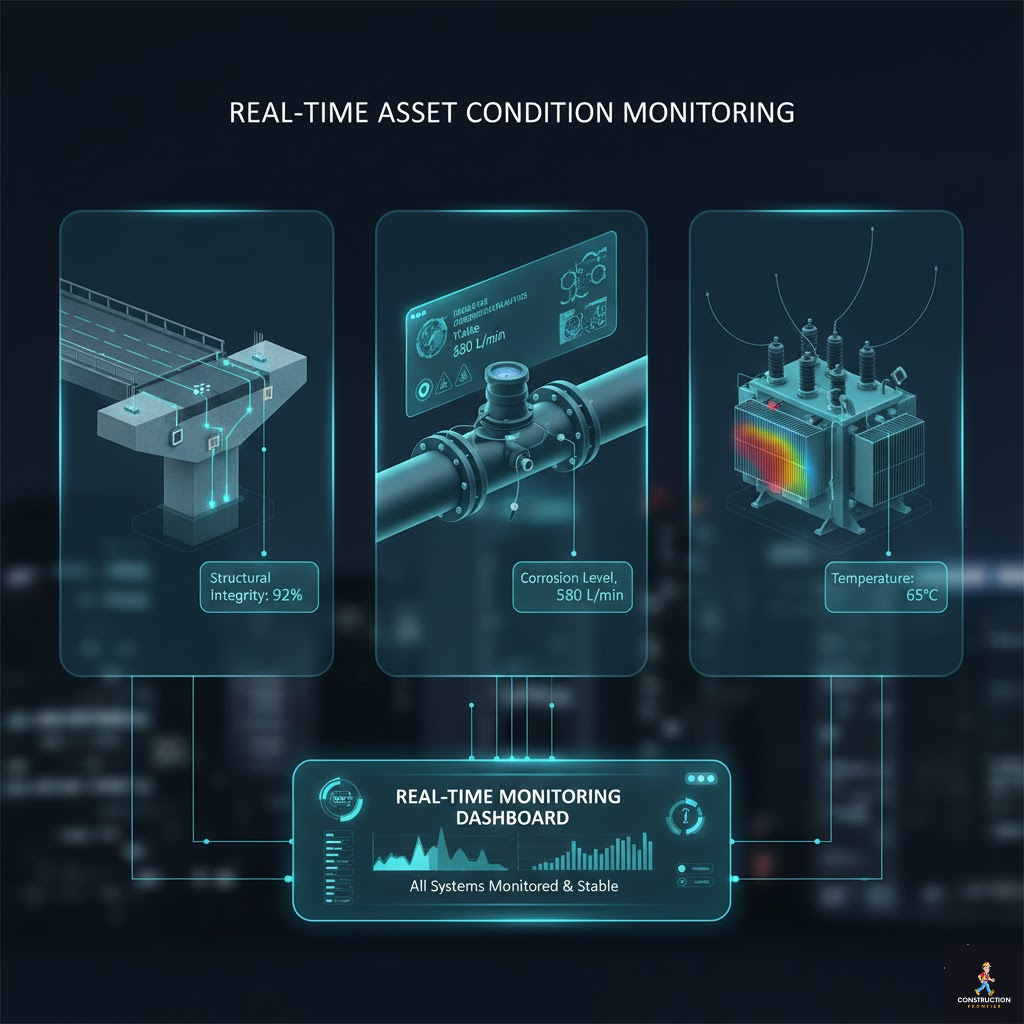

1. Real-Time Asset Condition Monitoring

Real-time monitoring is the foundation of IoT in infrastructure. Sensors embedded within assets continuously measure physical and operational parameters that indicate the health of the asset.

Unlike periodic inspections that provide only snapshots in time, IoT-based monitoring offers uninterrupted visibility into asset behaviour. Engineers can observe how assets respond to traffic loads, operational stress, and environmental conditions as they occur.

For example, sensors installed on bridges can track strain, vibration, and structural movement. Small changes in these parameters may indicate fatigue, cracking, or foundation settlement long before visible damage appears.

This continuous visibility enhances safety, facilitates early intervention, and underpins effective smart infrastructure maintenance utilising IoT technology.

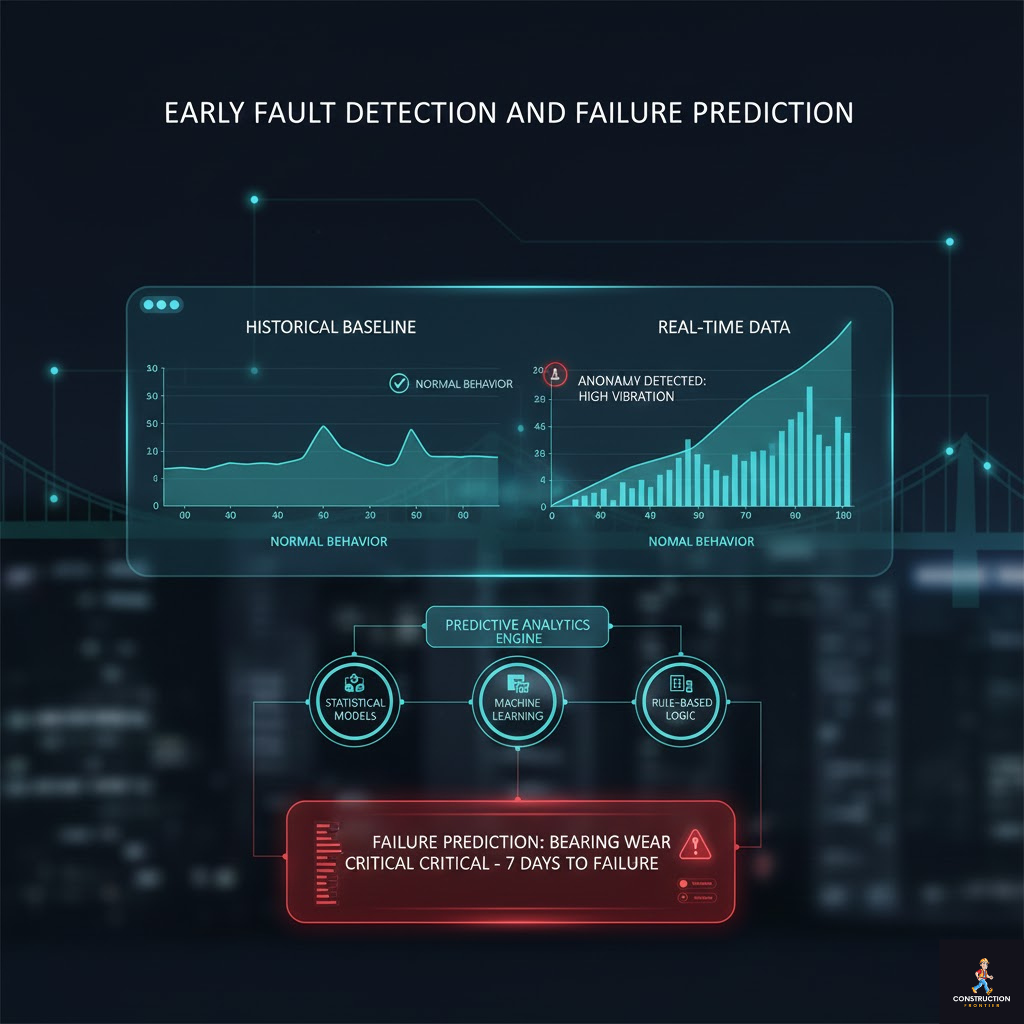

2. Early Fault Detection and Failure Prediction

IoT in infrastructure enables early fault detection by identifying abnormal patterns in sensor data. Systems compare real-time readings against historical baselines to detect deviations that signal emerging problems.

Threshold-based alerts notify operators when parameters exceed safe limits. More advanced systems analyse trends to detect gradual deterioration that may not trigger immediate alarms.

In water infrastructure, IoT sensors detect pressure drops, flow irregularities, and pump inefficiencies that indicate leaks or mechanical wear. Early detection reduces water losses, prevents ground damage, and avoids disruptive emergency repairs.

This capability is central to IoT-based asset management and significantly reduces the likelihood of catastrophic failures.

Further reading: 7 Innovative Engineering Intelligent Water Supply Systems for High-Performance Buildings

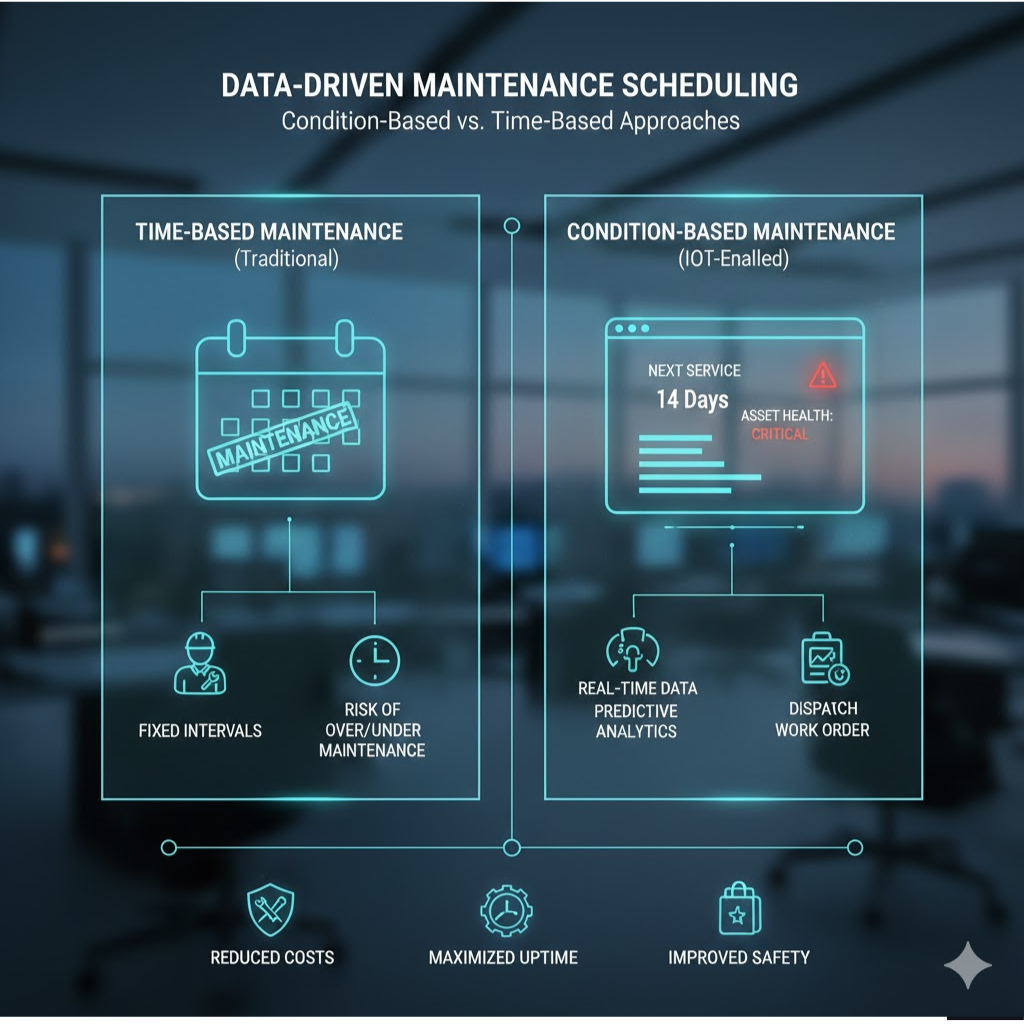

3. Data-Driven Maintenance Scheduling

One of the most transformative impacts of IoT in infrastructure is the shift from time-based to condition-based maintenance scheduling. IoT enables condition-based maintenance schedules, which reduce unnecessary inspections and operational costs. These systems are closely aligned with predictive maintenance using AI in public infrastructure, providing actionable intelligence that supports reliability and cost-efficiency.

Maintenance activities are planned based on the actual condition of the asset, usage intensity, and environmental exposure, rather than fixed calendars. Assets under higher stress receive timely attention, while those performing well are serviced less frequently.

For transport authorities, this approach reduces traffic disruptions by aligning maintenance windows with real needs. Utility operators benefit from fewer shutdowns and improved service reliability. Data-driven scheduling enhances workforce efficiency, minimises unnecessary inspections, and reduces overall operational costs.

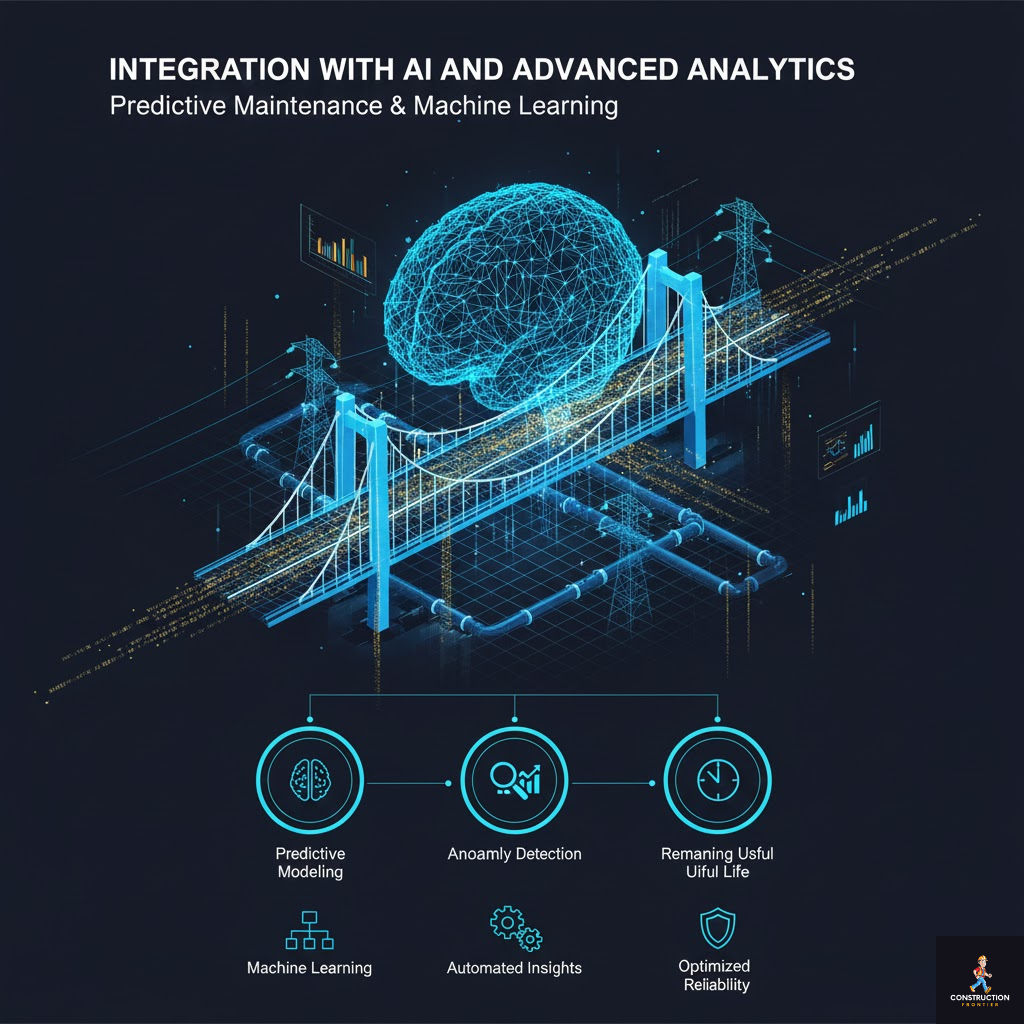

4. Integration with AI and Advanced Analytics

The full potential of IoT in infrastructure is unlocked when sensor data is combined with artificial intelligence and advanced analytics. Predictive maintenance utilises machine learning to analyse large datasets, identifying complex relationships between operating conditions, environmental factors, and asset degradation. These models estimate remaining useful life and forecast failure probabilities.

Rail systems, for example, in Finland, the VR Group manages a fleet of 1500 trains and uses IoT sensors and AI to predict track wear, wheel defects, and signalling failures before they disrupt services. As datasets grow, intelligent infrastructure systems continuously improve prediction accuracy. This integration enables truly proactive maintenance rather than a reactive response.

5. Cost Reduction and Asset Lifecycle Optimisation

From a financial perspective, IoT in infrastructure delivers strong value across the asset lifecycle. Predictive maintenance reduces emergency repair costs, which are often several times higher than planned interventions. An extended asset lifespan delays expensive replacements and improves return on investment (ROI).

Improved data also supports better budgeting, more accurate capital planning, and stronger accountability. For governments and infrastructure owners, IoT-driven maintenance transforms maintenance spending from a reactive expense into a strategic investment.

IoT in Infrastructure at a Glance

| Aspect | Traditional Maintenance | IoT-Enabled Predictive Maintenance |

| Monitoring | Periodic inspections | Continuous real-time monitoring |

| Failure response | Reactive | Predictive |

| Maintenance timing | Fixed schedules | Condition-based |

| Cost control | High emergency costs | Optimised lifecycle costs |

| Asset lifespan | Shortened by failures | Extended through early intervention |

Case Examples of IoT-Enabled Predictive Maintenance

Real-world applications provide the strongest evidence of how IoT in infrastructure shifts maintenance from reactive interventions to predictive, data-driven decision-making. Across transport, water, and energy sectors, IoT-enabled systems are already reducing failures, optimising operational expenditure, and improving public service reliability.

1. Smart Transport Systems

Urban transport infrastructure is one of the earliest beneficiaries of IoT-enabled predictive maintenance due to its high asset density and safety-critical nature. Embedded sensors within traffic lights and control cabinets track parameters such as voltage stability, signal response times, temperature, and the frequency of component cycling.

By continuously analysing this data, the system can identify early signs of equipment degradation, including relay fatigue, controller overheating, or power supply instability. Maintenance teams receive alerts before full signal failure occurs, allowing planned interventions rather than emergency repairs. This predictive approach reduces signal downtime, improves intersection safety, and minimises traffic congestion caused by unexpected outages. These IoT deployments reflect the trends seen in the top ten smart cities, where integrated data systems optimise traffic, utilities, and public services.

Beyond traffic signals, similar IoT-based predictive maintenance frameworks are being deployed for:

- Bridge health monitoring, using strain gauges and vibration sensors to detect fatigue and structural anomalies

- Road pavement condition monitoring, where embedded sensors and mobile data capture detect rutting, cracking, and surface deterioration

- Rail infrastructure, including track condition sensors and rolling stock monitoring for wheel, bearing, and braking system health

Case Study:

A landmark implementation in the railway sector, specifically on the UK’s East Coast Main Line, utilises Hitachi Rail’s digital monitoring solution. By mounting AI-enabled cameras and vibration sensors on LNER Azuma trains, the system captures real-time data on overhead lines and track stability. This data is processed through machine learning to identify structural deviations before they cause service interruptions, resulting in a 30% reduction in maintenance costs and a significant increase in network reliability.

Similarly, in Amsterdam, IoT sensors embedded in the city’s 3D-printed steel footbridge provide continuous structural health checks, enabling engineers to proactively address stress-induced cracks or deformations and avoid unplanned closures.

In Kenya, Nairobi’s smart traffic management system integrates IoT sensors, CCTV cameras, adaptive traffic signals, and centralised analytics platforms to monitor traffic flow, signal performance, and roadside equipment condition in real time.

For transport authorities, the key value lies in risk-based maintenance prioritisation, where resources are allocated to assets with the highest failure probability, rather than adhering to fixed inspection schedules.

2. Water Infrastructure

Water infrastructure systems are particularly vulnerable to hidden failures, making them ideal candidates for IoT-enabled predictive maintenance. Utilities deploy IoT sensors across distribution networks, pumping stations, reservoirs, and treatment plants to monitor flow rates, pressure fluctuations, vibration, acoustic signals, and energy consumption. Advanced leak detection sensors use pressure transients and acoustic signatures to identify pipe leaks long before they become visible at the surface.

IoT sensors in water pipelines, pumping stations, and electrical substations allow operators to predict failures before they occur. Combining IoT data with advanced visualisation tools can improve inspections and field decision-making, similar to AR/VR applications in construction, which are revolutionising training and site walkthroughs.

Pump and motor monitoring systems track parameters such as vibration frequency, bearing temperature, motor current, and runtime efficiency. Deviations from baseline performance profiles indicate early mechanical wear, cavitation risk, or electrical faults. Predictive analytics platforms then estimate remaining useful life and recommend maintenance windows aligned with operational demand.

For utilities facing high levels of non-revenue water, IoT-driven predictive maintenance delivers measurable benefits:

- Reduction in water losses through early leak detection.

- Lower energy costs through optimised pump operation.

- Extended asset lifespan for pipes, valves, and electromechanical equipment.

- Improved service continuity and pressure stability.

Case Study:

SeeMyMachines’ integrated industrial IoT solutions to transform the maintenance of critical water distribution infrastructure. By deploying advanced sensors across 174 pumps to monitor real-time vibration, temperature, and flow rates, the system transitioned operations from manual inspections to automated, data-driven oversight.

This predictive approach reduced unplanned downtime by 12% and extended the functional lifespan of assets by 15% by allowing technicians to intervene only when anomalies were detected. According to reports from Asia Growth Partners, these efficiencies saved approximately 4,800 man-hours in a single year, while significantly reducing non-revenue water loss through more precise asset management.

In rapidly growing urban centres, these systems also support demand forecasting and network resilience planning, enabling utilities to anticipate stress points before failures occur.

3. Energy Infrastructure

Energy systems rely heavily on asset reliability, making predictive maintenance crucial for maintaining grid stability and ensuring service continuity. Power utilities utilise IoT sensors and intelligent electronic devices to monitor the health of transformers, substations, transmission lines, and distribution networks. Key indicators, including oil temperature, dissolved gas analysis, partial discharge, load cycles, and voltage harmonics, are continuously monitored.

Predictive analytics models correlate these parameters with historical failure data to identify patterns of degradation. For example, abnormal gas generation in transformer oil can signal insulation breakdown long before a catastrophic failure occurs. Early detection enables planned transformer servicing or replacement, avoiding costly outages and safety hazards.

In substations, IoT-based monitoring systems assess breaker operation cycles, contact wear, and thermal stress. Grid-level analytics enable utilities to predict overload conditions, manage peak demand, and enhance fault isolation response times.

For energy providers, the operational impact includes:

- Reduced unplanned outages and improved grid reliability.

- Lower maintenance costs through condition-based interventions.

- Enhanced safety for field personnel and surrounding communities.

- Improved compliance with regulatory reliability standards.

Case Study:

Energy infrastructure leaders, such as EDF Energy and Ørsted, have utilised the Schneider Electric EcoStruxure platform and Microsoft Azure to implement IoT-driven predictive maintenance across power plants and offshore wind farms. By deploying thousands of sensors to monitor real-time vibration, temperature, and electrical signatures of critical assets, such as turbines and transformers, these utilities have transitioned from reactive repairs to data-driven foresight.

Real-world outcomes from these deployments include a 25% reduction in maintenance costs and a 12% decrease in unplanned downtime, effectively preventing costly grid failures. Furthermore, companies like Equinor have reported that integrating these IoT “digital twins” into remote operations can boost overall life-cycle profits by up to 10% while significantly reducing carbon emissions through optimised resource utilisation.

As renewable energy integration increases, IoT-enabled predictive maintenance becomes even more critical for managing variability and ensuring grid resilience. These case examples demonstrate that IoT applications in transport and utility infrastructure are no longer experimental. They are proven tools delivering measurable operational, financial, and safety benefits across multiple infrastructure sectors.

Challenges of Implementing IoT in Infrastructure

Despite its advantages, implementing IoT in infrastructure at scale presents several technical, organisational, and regulatory challenges that infrastructure owners must address strategically.

1. High Initial Deployment Costs

IoT-enabled predictive maintenance requires upfront investment in sensors, communication networks, data platforms, system integration, and cybersecurity frameworks. For public infrastructure agencies operating under constrained budgets, these capital costs can hinder the adoption of new technologies.

However, the challenge is often one of budget structure rather than affordability. Traditional procurement models prioritise capital expenditure minimisation rather than lifecycle cost optimisation. Without lifecycle-based financial frameworks, long-term operational savings are undervalued in investment decisions.

2. Data Security and Cybersecurity Risks

Connected infrastructure systems increase exposure to cyber threats, including data breaches, system manipulation, and service disruption. Critical infrastructure assets such as power grids, water systems, and traffic control networks are particularly sensitive targets.

Effective mitigation requires:

- End-to-end encryption of data streams.

- Strong identity and access management.

- Continuous network monitoring and anomaly detection.

- Clear cybersecurity governance frameworks.

Without robust cybersecurity strategies, the risks can outweigh the operational benefits of IoT deployment.

3. Connectivity Limitations

Reliable data transmission is essential for real-time predictive maintenance. In many regions, especially rural and peri-urban areas, network coverage remains inconsistent.

Limited connectivity in IoT restricts sensor deployment, delays data transmission, and reduces system effectiveness. Hybrid communication architectures combining cellular, low-power wide-area networks, satellite links, and edge computing are often required to overcome this challenge.

4. Skills and Data Management Gaps

IoT systems generate large volumes of data related to asset performance. Transforming this data into actionable maintenance decisions requires expertise in:

- Data analytics and machine learning.

- Asset management systems.

- Reliability engineering.

- Digital infrastructure platforms.

Many infrastructure organisations face skills gaps in the IoT field in these areas. Without adequate training and institutional capacity building, IoT deployments risk becoming underutilised or misinterpreted.

5. Regulatory and Interoperability Challenges

The lack of standardisation across IoT devices, platforms, and data formats complicates integration across agencies and asset types. Regulatory frameworks in IoT development often lag behind technological advances, creating uncertainty around data ownership, privacy, and cross-agency data sharing. Interoperability challenges can lead to fragmented systems that limit scalability and long-term value.

The Future of IoT-Driven Predictive Maintenance

The future of infrastructure maintenance is digital, predictive, and system-integrated. IoT in infrastructure is increasingly converging with digital twins, BIM platforms, artificial intelligence, and enterprise asset management systems.

Digital twins will enable infrastructure owners to simulate asset behaviour under various operating and environmental conditions, allowing for predictive maintenance strategies that account for climate stress, demand growth, and ageing assets.

In emerging markets, adoption is expected to accelerate as smart city programmes expand and infrastructure investment increases. Public-private partnerships, outcome-based procurement models, and supportive regulatory frameworks will play a critical role in scaling deployment.

Ultimately, the future of infrastructure maintenance using IoT points towards assets that are safer, more resilient, more cost-efficient, and better aligned with long-term sustainability goals.

Conclusion: Why IoT Is the Future of Infrastructure Maintenance

IoT in infrastructure is fundamentally changing how physical assets are monitored, maintained, and managed over their lifecycle. By enabling real-time condition monitoring, early fault detection, data-driven maintenance scheduling, AI-powered analytics, and lifecycle optimisation, predictive maintenance shifts from theory to a practical, scalable approach for modern infrastructure systems.

The five smart ways discussed in this article show that the benefits of IoT for infrastructure maintenance and monitoring extend well beyond short-term cost savings. They improve operational reliability, enhance public safety, reduce unplanned downtime, and support more informed capital planning decisions. As infrastructure assets face increasing pressure from ageing, urban growth, and climate stress, IoT in infrastructure is no longer an optional digital upgrade. It is becoming a core requirement for building resilient, efficient, and sustainable public infrastructure.

Call to Action: Stay Ahead of Infrastructure Innovation

Stay ahead in infrastructure management with ConstructionFrontier.com. Access expert insights on IoT-driven predictive maintenance, smart infrastructure monitoring, and real-world African case studies to improve asset reliability, reduce costs, and make data-driven decisions. Follow us today to lead the way in building smarter, safer, and more resilient infrastructure networks.