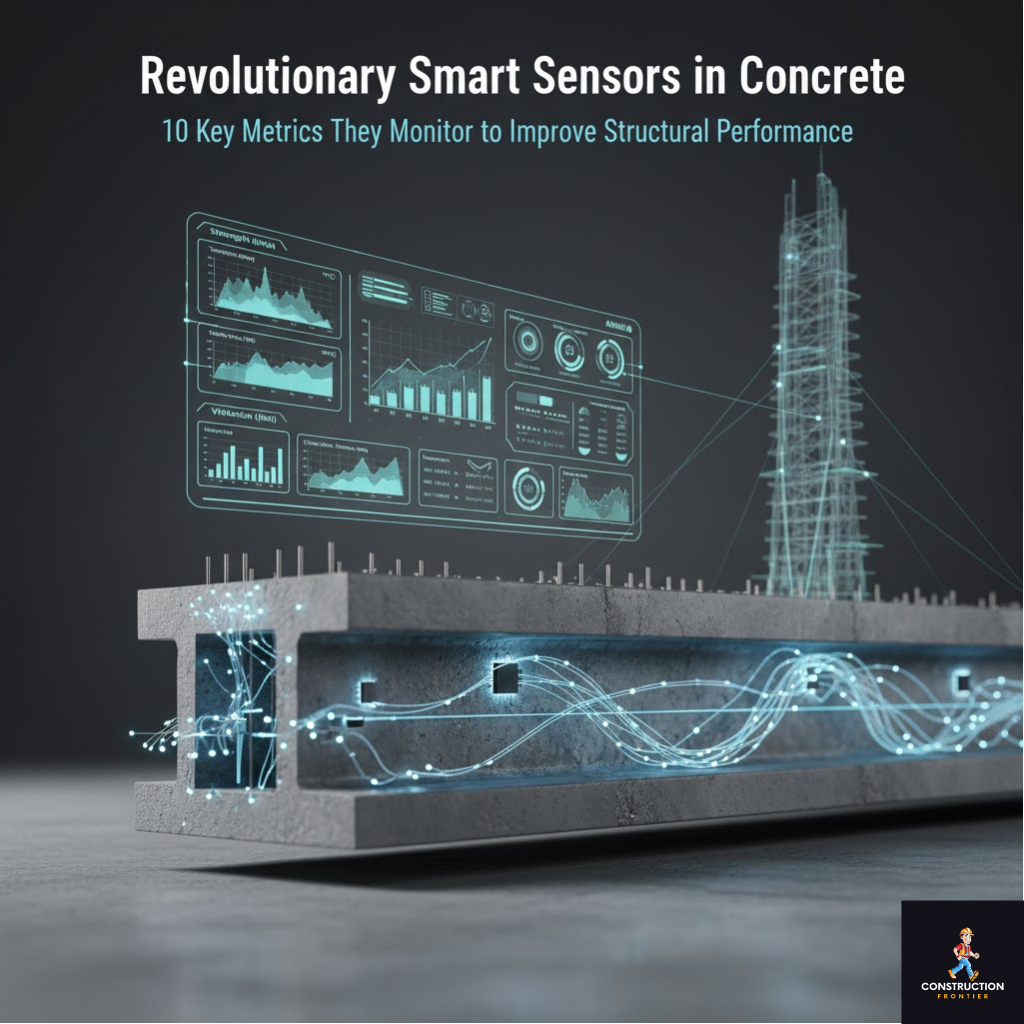

Revolutionary Smart Sensors in Concrete: 10 Key Metrics They Monitor to Improve Structural Performance

Concrete has always been the backbone of modern infrastructure — but today, it is getting smarter. With embedded digital systems, smart sensors in concrete are transforming how engineers design, monitor and maintain structures. From real-time strength tracking to long-term structural health insights, this technology is redefining efficiency, safety and durability in construction.

Smart Concrete, Smarter Structures: How Digital Sensors Are Transforming Performance

Concrete is the world’s most widely used construction material, yet its behaviour has long relied on prediction, laboratory samples and periodic physical tests. But with the rise of smart sensors in concrete, engineers now gain live, continuous, highly accurate insights into what is happening inside a structure at every stage, from early curing to decades-long operational life.

These embedded devices form part of an evolving ecosystem of concrete monitoring technology, structural health sensors, and IoT in construction, enabling fully connected job sites where data replaces guesswork. Unlike traditional cubes and destructive testing methods, these digital sensors track real-time conditions that directly influence structural safety, durability and long-term performance.

This article breaks down 10 critical metrics monitored by smart sensors in concrete, why they matter, and how modern real-time monitoring systems are reshaping innovative technology in modern construction projects. From temperature gradients to moisture migration, crack development and even corrosion activity, smart construction materials are unlocking new opportunities to build stronger, longer-lasting and more resilient infrastructure.

10 Essential Metrics Smart Sensors in Concrete Monitor for Superior Structural Performance

Modern concrete structures face greater demands than ever before, from heavier loads to extreme climates and accelerated construction schedules. To meet these challenges, engineers increasingly rely on advanced smart sensors in concrete that deliver real-time data during curing, construction, and long-term service life. These embedded systems track multiple performance indicators, enabling contractors, designers, and asset owners to make informed decisions that improve durability, safety, and lifecycle efficiency. Below, we explore the ten critical metrics that smart sensors in concrete monitor and why each one matters.

1. Temperature Profile Inside Concrete

Temperature is one of the most influential factors affecting curing, hydration rates, and long-term concrete performance. Smart sensors provide real-time temperature monitoring from the moment the mix is poured, offering insights that traditional methods simply cannot match.

Why Temperature Matters

- Excessive heat leads to rapid hydration, shrinkage, and thermal cracking.

- Low temperatures slow down curing, delaying strength gain and causing incomplete hydration.

- Large concrete pours, such as dams, bridge piers, and massive foundations, can develop harmful internal temperature gradients.

How Monitoring Improves Performance

- Ensures concrete stays within a safe temperature window during curing.

- Helps contractors adjust insulation, cooling, or curing methods in real time.

- Minimises delays in cold-weather or hot-weather concreting.

- Reduces risks associated with thermal cracking and differential cooling.

2. Real-Time Concrete Strength Monitoring

Smart sensors allow engineers to track compressive strength development without relying solely on cube or cylinder tests, which often fail to reflect in-situ conditions. Using temperature-maturity relationships, sensors provide accurate, live strength estimations.

Why Strength Monitoring Matters

- Supports early and safe formwork removal.

- Enables timely post-tensioning operations.

- Reduces reliance on destructive testing.

- Improves scheduling accuracy for applying loads or commencing the following stages of work.

Real-time concrete strength monitoring dramatically reduces downtime and enhances construction efficiency.

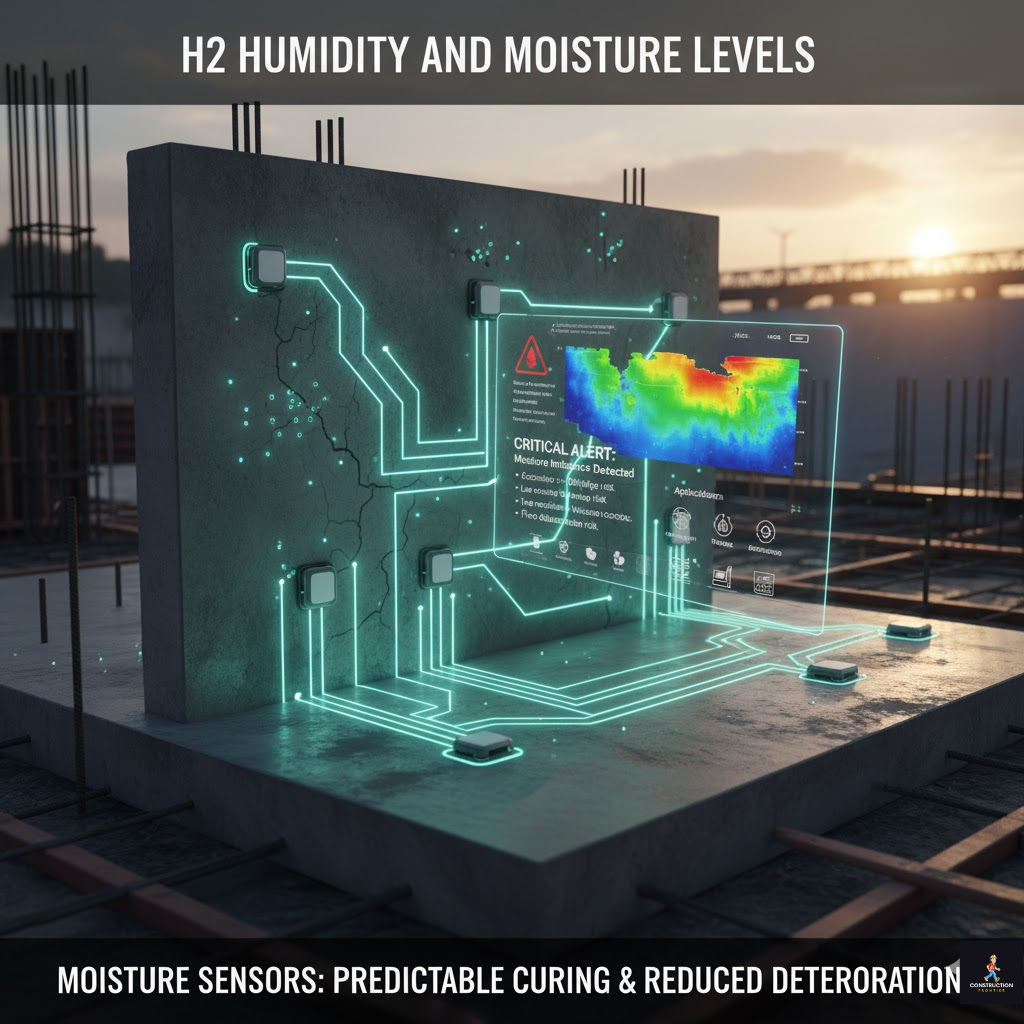

3. Humidity and Moisture Levels

Moisture plays a crucial role in hydration and durability. Smart sensors monitor internal moisture conditions in concrete from curing through the structure’s lifecycle.

Why Moisture Monitoring is Critical

- Excessive moisture increases the risk of shrinkage cracking.

- Low moisture slows hydration and weakens concrete.

- Moisture imbalance can cause delamination or adhesion failures in flooring systems.

Applications

- Determining safe installation times for floor coverings.

- Monitoring water-retaining structures such as reservoirs and tanks.

- Enhancing durability in tunnels, bridges, and marine environments.

Moisture sensors ensure predictable curing and reduced long-term deterioration.

4. Crack Detection and Micro-Crack Development

Early crack detection in concrete is one of the most powerful capabilities of structural health sensors. These sensors identify crack initiation long before visible damage appears.

Why Crack Detection Matters

- Provides early warnings before cracks propagate into structural failures.

- Allows targeted maintenance instead of costly full-scale repairs.

- Helps engineers understand stress patterns and reinforcement performance.

- Ideal for seismic regions, heavy-load bridges, marine structures, and retaining walls.

Crack detection enhances both safety and asset lifespan in all types of infrastructural projects.

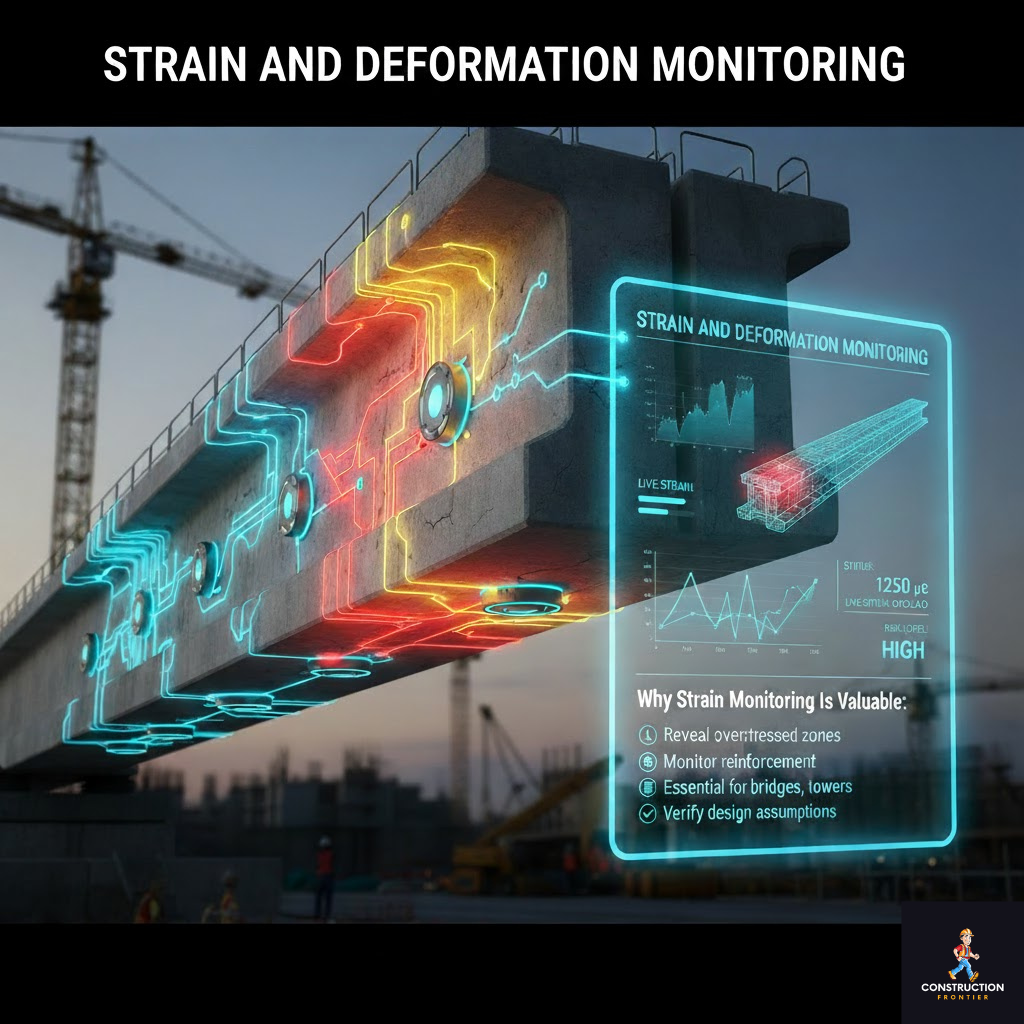

5. Strain and Deformation Monitoring

Strain and deformation gauges installed on concrete surfaces measure how concrete deforms under load, giving engineers insights into whether actual behaviour aligns with design expectations.

Why Strain Monitoring Is Valuable

- Reveals overstressed or underperforming structural zones.

- Monitors how reinforcement and prestressing behave in real conditions.

- Essential for real-time monitoring of bridges, towers, high-rise buildings, and industrial facilities.

- Helps verify design assumptions and supports future optimisation.

Strain monitoring makes modern structures smarter, safer, and more predictable.

6. Vibration and Dynamic Response

Vibration sensors in concrete assess how structures respond to external forces such as traffic, machinery, wind, and seismic activity.

Key Benefits

- Detect abnormal vibration patterns that may indicate hidden structural issues.

- Prevent fatigue-related damage in long-span bridges, factories, and high-rise buildings.

- Protect sensitive facilities like hospitals, laboratories, and manufacturing plants.

- Provide rapid insights during post-earthquake evaluations.

Dynamic monitoring improves resilience in busy urban or seismic locations.

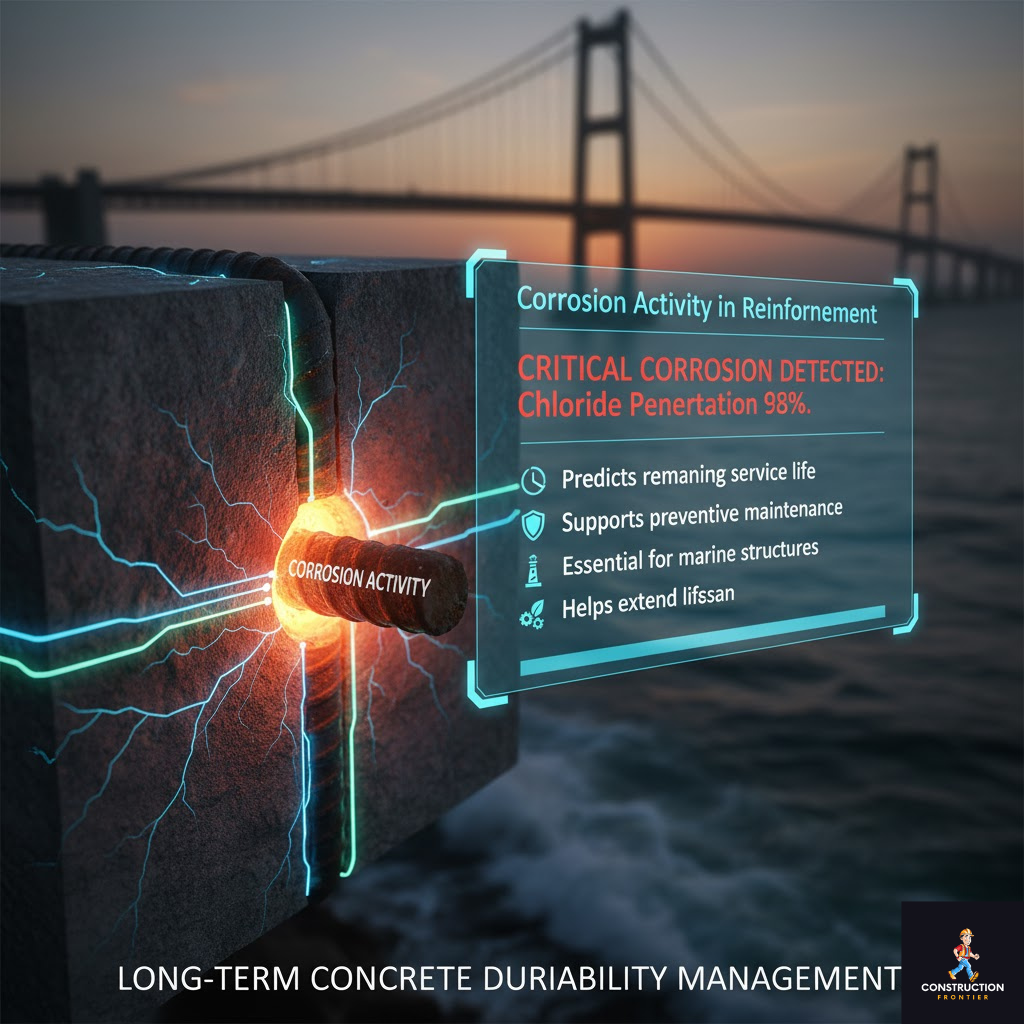

7. Corrosion Activity in Reinforcement

Corrosion of reinforcement bars is one of the most common causes of concrete deterioration. Smart sensors track corrosion potential, moisture exposure, and chloride penetration.

Why Corrosion Monitoring Is Crucial

- Predicts remaining service life with high accuracy.

- Supports preventive maintenance before major failures occur.

- Essential for marine structures, coastal bridges, basements, and industrial plants.

- Helps extend lifespan in structures exposed to saltwater, chemicals, or humidity.

Corrosion sensors are a cornerstone of long-term concrete durability management.

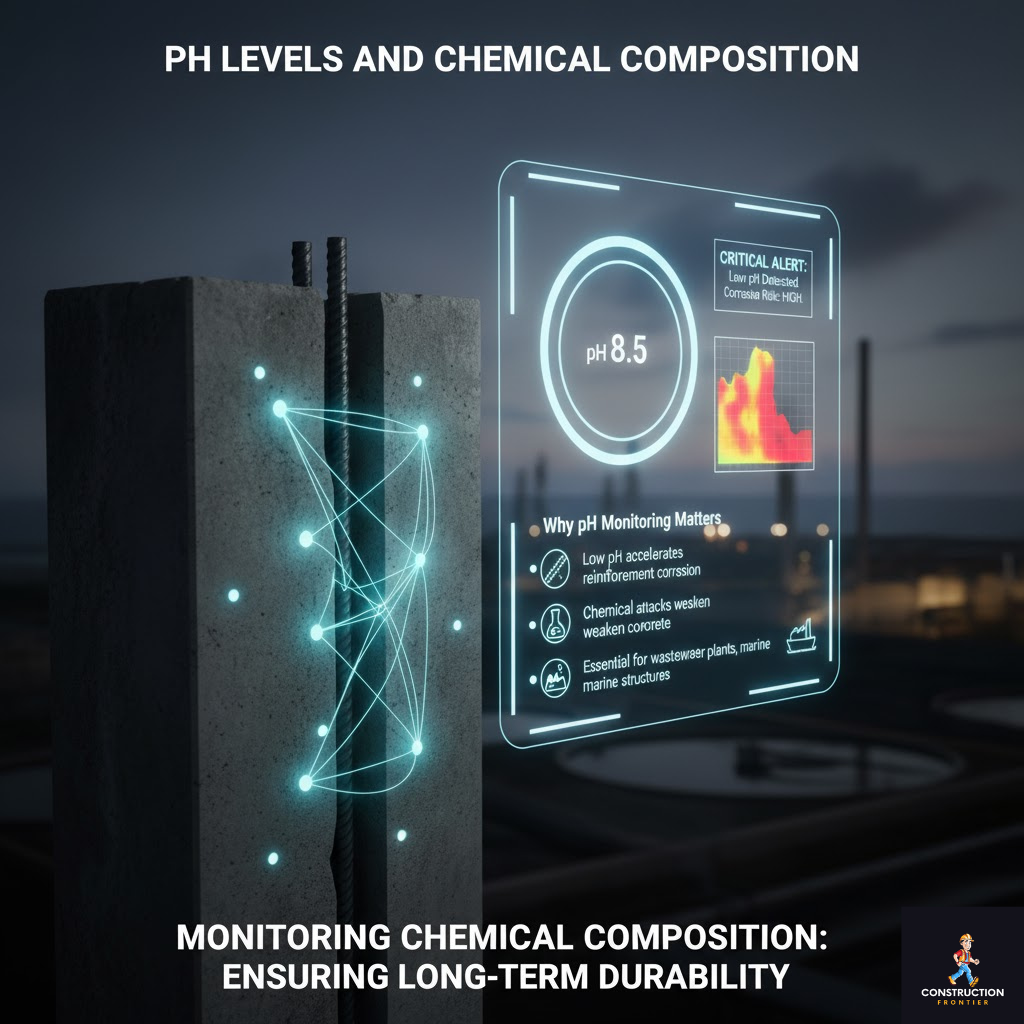

8. pH Levels and Chemical Composition

Concrete’s natural alkalinity protects reinforcement from corrosion. Over time, chemical attacks, carbonation, and industrial exposure reduce pH levels.

Why pH Monitoring Matters

- Low pH accelerates reinforcement corrosion.

- Chemical attacks from sulphates, chlorides, or industrial effluents weaken concrete.

- Essential for wastewater plants, chemical factories, marine structures, and tunnels.

Monitoring chemical composition by use of electrochemical sensors in concrete structures helps ensure concrete retains its protective properties.

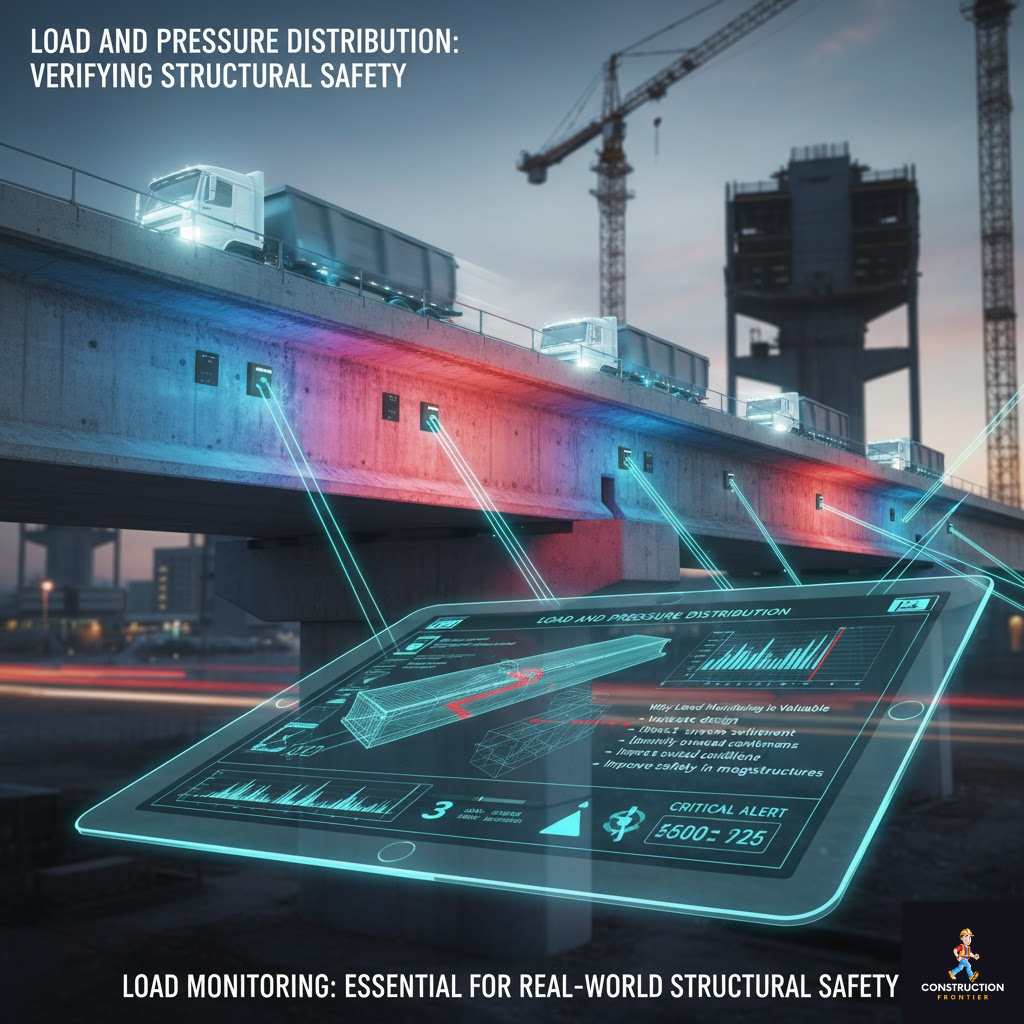

9. Load and Pressure Distribution

Some advanced smart sensors in concrete measure load transfer and pressure distribution across elements such as slabs, beams, columns, and foundations.

Benefits of Load Monitoring

- Validates whether the structure is performing as designed.

- Detects uneven settlement early.

- Identifies overload conditions in high-traffic buildings or bridges.

- Improves safety in stadiums, airports, industrial floors, and megastructures.

Load monitoring in concrete structures is essential for verifying structural safety under real-world conditions.

10. Long-Term Structural Health and Behaviour

One of the greatest advantages of IoT-enabled concrete sensors is long-term performance tracking. These sensors remain embedded throughout the structure’s service life.

Why Long-Term Monitoring Matters

- Supports predictive maintenance strategies.

- Enables early detection of deterioration.

- Improves asset management for public and private infrastructure owners.

- Essential for critical assets such as tunnels, dams, airports, and highways.

Long-term monitoring transforms concrete structures into intelligent, self-reporting systems that enhance safety and reduce lifecycle costs.

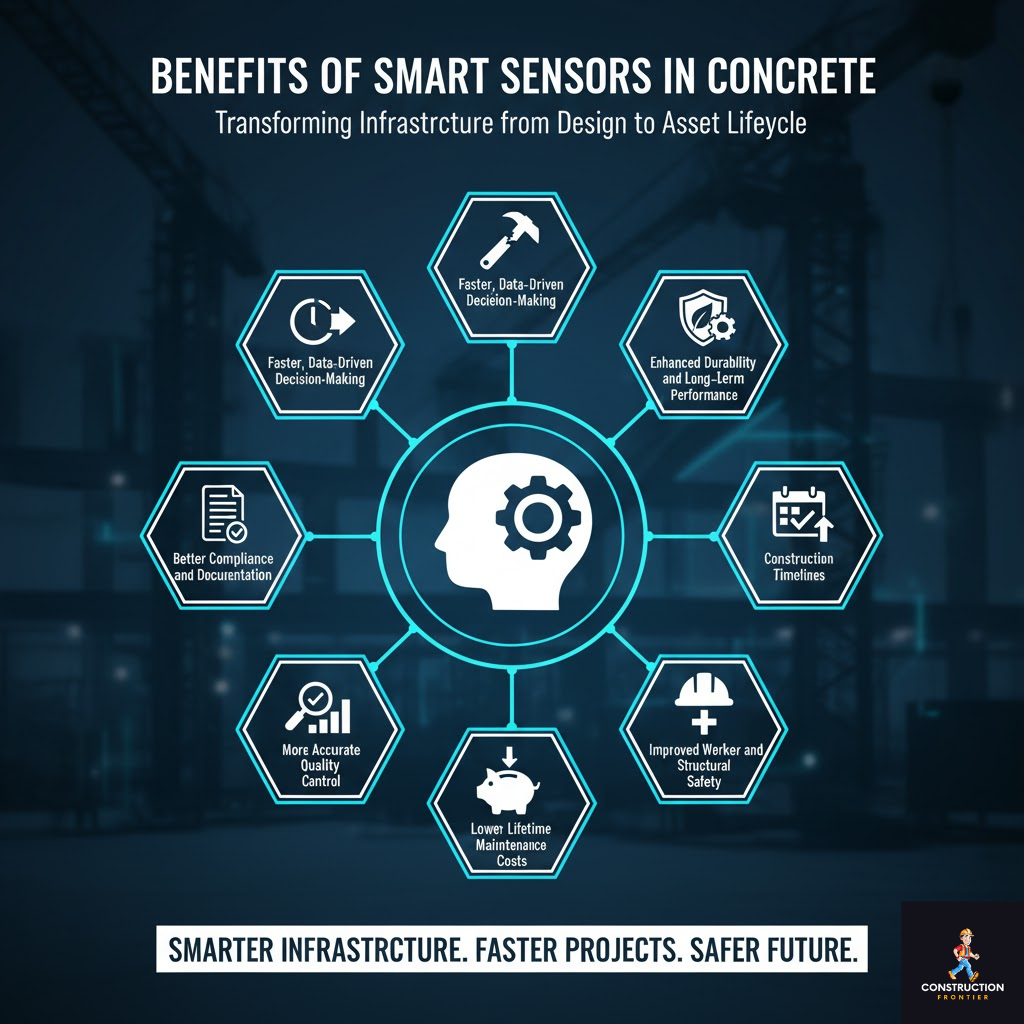

Benefits of Smart Sensors in Concrete

Smart sensors in concrete unlock a broad spectrum of advantages that strengthen decision-making, speed up project delivery, and enhance long-term structural resilience. Their benefits extend far beyond simple monitoring; they reshape how contractors, consultants, and asset owners plan, build, and maintain infrastructure.

1. Faster, Data-Driven Decision-Making

Real-time data enables immediate responses to curing issues, temperature spikes, load changes, or early-warning structural indicators. Engineers no longer need to rely on periodic inspections or laboratory tests, significantly reducing uncertainty.

2. Reduced Dependence on Destructive Testing

Smart concrete sensors reduce the need for core drilling and excessive cylinder testing. This lowers labour costs, shortens testing cycles, and preserves structural integrity.

3. Enhanced Durability and Long-Term Performance

Early detection of moisture intrusion, corrosion risk, or micro-cracking improves asset longevity. Monitoring ensures that preventive maintenance happens at the ideal time — not too early and not too late.

4. Accelerated Construction Timelines

Real-time concrete strength monitoring allows teams to remove formwork, schedule post-tensioning, or proceed with upper floors sooner. Projects gain days or even weeks on the programme.

5. Improved Worker and Structural Safety

Sensors minimise human exposure to hazardous inspections and identify structural concerns before they escalate. They provide early warnings for overstress, excessive movement, or thermal cracking.

6. Lower Lifetime Maintenance Costs

Smart sensors highlight issues before significant deterioration occurs, allowing asset owners to plan targeted, low-cost maintenance instead of major rehabilitation.

7. More Accurate Quality Control

Because sensors provide continuous readings instead of snapshots, contractors can validate curing quality, strength development, and material performance with granular accuracy.

8. Better Compliance and Documentation

Digital records support quality audits, safety certifications, and contractual verification, ensuring transparent project delivery and improved dispute resolution.

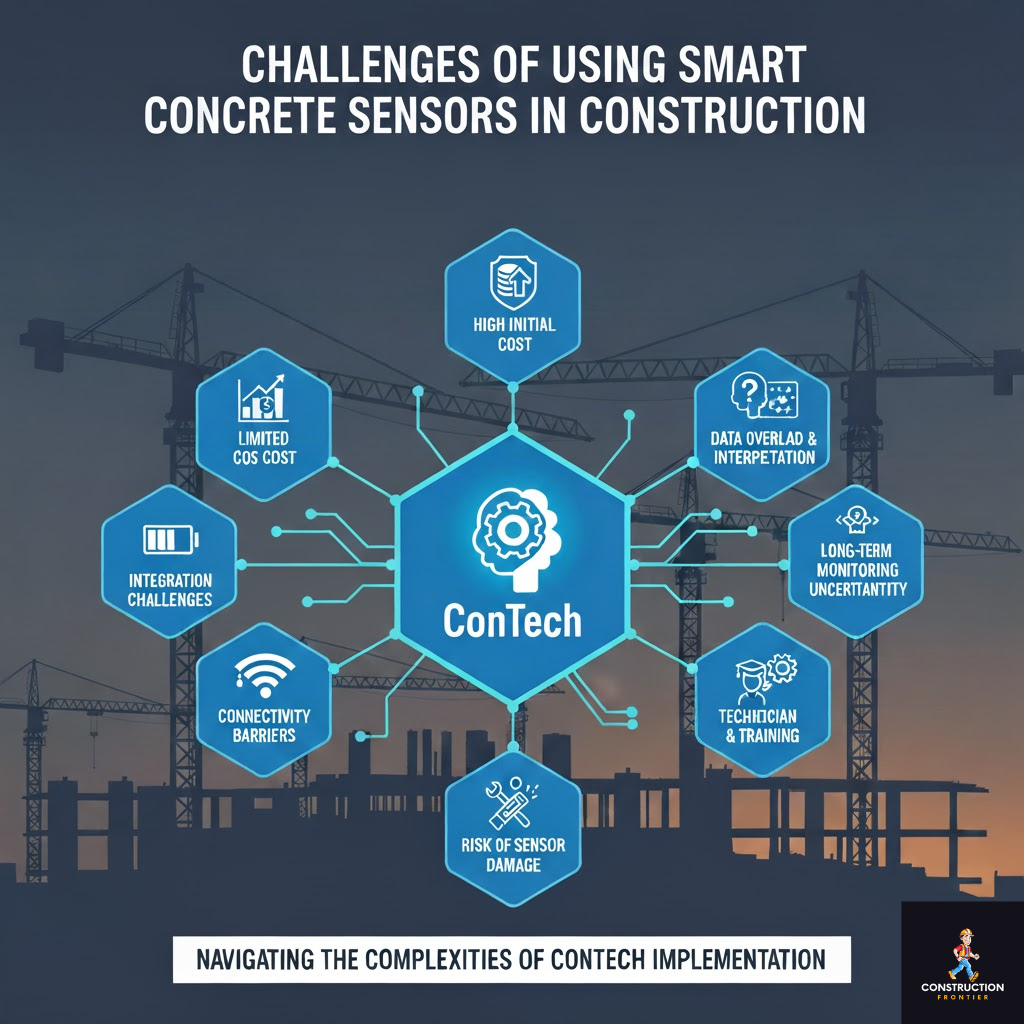

Challenges of Using Smart Concrete Sensors in Construction

Despite their transformative benefits, smart sensors in concrete also come with practical and economic challenges that must be considered. These limitations vary by technology, project type, and installation method.

1. High Initial Cost

Advanced sensor systems can be expensive, especially for large-scale projects requiring dozens or hundreds of units. Budget-constrained projects may struggle to justify upfront expenditure.

2. Limited Sensor Lifespan

Some concrete monitoring technology relies on embedded sensors that may degrade over time due to chemical exposure, heat, or long-term structural stress.

3. Data Overload and Interpretation Issues

Massive data streams require qualified engineers and specialised software. Misinterpretation can lead to incorrect decisions, compromising structural performance.

4. Integration Challenges

Existing site workflows, construction sequences, and digital platforms may not seamlessly integrate with IoT in construction systems.

5. Connectivity Barriers

Underground facilities, high-density reinforcements, or thick concrete masses may disrupt wireless transmission, reducing data reliability.

6. Technician and Training Requirements

Installing, calibrating, and maintaining sensors demands skilled personnel that may not be available in all markets, especially remote locations.

7. Risk of Sensor Damage During Construction

Sensors embedded in concrete may be accidentally damaged during rebar installation, compaction, or subsequent drilling works.

8. Long-Term Monitoring Uncertainty

Some sensors have untested long-term performance beyond 20–30 years, making durability projections less certain.

Conclusion: Smart Sensors Are Redefining Modern Construction

Smart sensors in concrete are reshaping how modern infrastructure is designed, built and maintained. By combining concrete monitoring technology, real-time concrete strength monitoring, and advanced IoT in construction systems, engineers gain clearer visibility into structural behaviour than ever before. This leads to faster decision-making processes, reduced risks and more durable assets.

Looking ahead, the adoption of real-time concrete strength monitoring and fully connected digital systems will only increase as the industry shifts toward predictive maintenance, AI in civil engineering and data-driven design. While challenges remain from data integration to the cost of specialised structural health sensors, the long-term value is undeniable. As adoption grows, smart construction technology will continue to transform project delivery, making structures safer, more efficient, and built for the future.

Call to Action: Build Smarter, Build Stronger

Want more profound insights into the newest construction innovations and engineering technologies shaping tomorrow’s infrastructure? Visit ConstructionFrontier.com for expert analysis, industry trends, and breakthrough technologies changing construction across Africa and the world.