Top 10 Cement Brands in Africa Powering the Infrastructure Boom

Africa’s infrastructure is expanding at a rate never seen before, thanks to population growth, urbanisation, regional trade integration, and ambitious government development plans. High-quality building materials are in high demand as megaprojects, ranging from highways and railroads to energy plants and commercial centres, proliferate throughout the continent. Cement remains one of the most critical inputs among them.

According to the African Development Bank (AfDB), Africa’s cement consumption surpassed 250 million tonnes in 2023 and is expected to reach over 290 million tonnes by 2025. These numbers demonstrate the enormous demand for strong, effective cement to fulfil the continent’s development goals. With an emphasis on their production capacity, technological innovation, regional influence, and connection with sustainability aims, this article delves into the top 10 cement brands in Africa, driving this construction revolution.

Why Cement Brands Matter in Construction

When selecting the top 10 cement brands in Africa, the quality of the cement was a key consideration, as it directly impacts the durability, safety, and longevity of structures. It determines properties such as:

- Setting Time: Refers to the rate at which cement hardens after water is added. Rapid-hardening cement is crucial in projects requiring quick turnaround, such as road repairs or precast installations, minimising downtime and labour costs.

- Compressive Strength: Indicates the ability of hardened concrete to resist axial loads. It is fundamental to the structural integrity of buildings, bridges, and industrial plants, and must align with national and international civil engineering codes.

- Durability: Represents the cement’s resistance to environmental aggressors, such as sulfates, chlorides, and moisture. Durable cement ensures longevity, especially in coastal or chemically active soils where corrosion and degradation are common.

- Shrinkage and Thermal Cracking: Concerns dimensional stability due to moisture loss and temperature fluctuations. Controlling these properties is vital in large structures, such as dams, highways, and retaining walls, to prevent stress-induced cracking.

- Workability: Relates to how easily cement in concrete can be mixed, placed, and finished. High workability enhances on-site efficiency, reduces segregation, and promotes uniform compaction, which is crucial for achieving the desired design strength.

These top 10 cement brands in Africa also lead in innovations such as low-carbon cement, enhanced logistics, and sustainable raw material sourcing, all of which are essential for today’s green construction mandates.

Methodology: How We Ranked the Top 10 Cement Brands

Our ranking of the top 10 cement brands in Africa, methodology included both qualitative and quantitative measures based on:

- Installed Production Capacity (MTPA): Measures a brand’s total cement output capability annually, directly affecting its ability to meet large-scale project demands and national consumption needs.

- Market Share and Geographic Footprint: Indicates the brand’s reach and influence across different African regions. A broader footprint enhances distribution efficiency and market resilience.

- R&D and Product Innovation: Reflects investment in developing new cement types, enhancing performance characteristics such as setting time and strength, and tailoring products to local construction needs.

- Sustainability and ESG Compliance: Evaluates efforts to reduce carbon emissions, use alternative fuels, and align with environmental and social governance standards.

- Involvement in Major Infrastructure Projects: Demonstrates practical validation through participation in flagship national and regional developments such as roads, dams, and housing schemes.

- Reputation Among Industry Professionals: Based on feedback from civil engineers, contractors, and project managers regarding quality consistency, availability, and technical support.

The Top 10 Cement Brands in Africa

Africa’s cement industry is as dynamic as the continent’s construction needs. The companies featured in this list were selected for their scale and influence in shaping Africa’s infrastructure story. These top 10 cement brands in Africa have distinguished themselves by consistently delivering high-quality cement products tailored to diverse construction conditions, adopting sustainability-driven production models, and actively contributing to transformative projects across transport, energy, and housing sectors. This section dives into the origins, capacities, and technical profiles of the continent’s most trusted cement manufacturers in Africa.

1. Dangote Cement (Nigeria)

Founded: Dangote Cement was created in 1981 by Aliko Dangote, one of Africa’s most prominent industrialists and entrepreneurs.

Shareholding: Publicly traded on the Nigerian Stock Exchange (NSE) in 2010; the major shareholder is Dangote Industries Limited.

With an installed capacity of over 51.6 million tonnes per annum (MTPA), Dangote Cement is the largest cement producer in Africa, making it the leading manufacturer of the top 10 cement brands on the continent. It operates integrated plants and grinding facilities across ten countries, including Nigeria, Ethiopia, Ghana, and South Africa.

Key Projects:

- Lagos–Ibadan Expressway Reconstruction.

- Nigerian Rail Modernisation Project.

- Abuja Mass Housing Scheme.

Technical Strengths:

- Low-heat cement is ideal for mass pours.

- CEM I and CEM II varieties are compliant with EN 197-1 standards.

- Automated kilns for quality consistency.

Dangote’s vertical integration—from limestone quarries to transportation—ensures pricing stability and control over the supply chain.

2. Lafarge Africa (Holcim Group)

Founded: Originally part of Lafarge SA (France) in 1833; Lafarge Africa PLC was established in Nigeria in 1959.

Shareholding: The majority is owned by Holcim Group (Switzerland) and is listed on the NSE.

Capacity:

- Over 12 MTPA across Nigeria, Malawi, Uganda, and Zimbabwe.

- First, LC3-based products will be launched in West Africa.

Highlight Projects:

- Lagos Lekki Free Trade Zone.

- Malawi Water Treatment Facilities.

Their blended cements (CEM II/B-M) optimise the use of pozzolanic materials, improving sulphate resistance and long-term durability.

3. Bamburi Cement (Kenya)

Founded: 1951 by Felix Mandl, a Kenyan industrialist.

Shareholding: The majority of the stake was formerly held by Holcim Group but is now held by Amson’s Group, and is listed on the Nairobi Securities Exchange.

Bamburi, majority-owned by Amson’s Group, is the leading cement brand in East Africa, with manufacturing plants in Nairobi and Mombasa, making it a controlling company in cement production. We therefore placed it third on the top 10 cement brands in Africa list.

Capacity:

- 2.3 MTPA.

- 70% market penetration in Kenya.

Notable Projects:

- Nairobi Expressway.

- Two Rivers Commercial Complex.

KEBS and ISO 9001 certified Bamburi’s PowerMax and Nguvu brands are trusted for structural, precast, and marine applications.

4. CIMAF (Ciments de l’Afrique – Morocco)

Founded: 2011 by Anas Sefrioui under the Addoha Group.

Shareholding: Fully owned by the Addoha Group (Morocco), a leading real estate and industrial conglomerate.

CIMAF has rapidly scaled across 15 African nations, becoming a leader of French-speaking West and Central Africa.

Capacity:

- Over 10 MTPA.

- Integrated plants in Ghana, Mali, Côte d’Ivoire, and the DRC.

Infrastructure Contributions:

- Côte d’Ivoire Abidjan Port Expansion.

- Guinea’s Kaleta Hydropower Dam.

CIMAF’s research and development teams have pioneered sulfate-resistant cement (SRC) and rapid-hardening cement tailored for tropical climates.

5. Mugher Cement (Ethiopia)

Founded: 1984 by the Government of Ethiopia.

Shareholding: Fully state-owned under the Ethiopian Industrial Inputs Development Enterprise.

One of Ethiopia’s oldest cement companies, Mugher, is state-owned and strategically vital to the country’s public works.

Capacity:

- 2.3 MTPA.

- Primary supplier to federal and regional projects.

Infrastructural Projects:

- GERD (Grand Ethiopian Renaissance Dam).

- Federal low-cost housing projects.

Mugher produces ASTM C150-compliant cement and is upgrading its kilns to reduce emissions under the national green construction plan.

6. Sinoma International (China/Africa)

Founded: 2001 as part of China National Building Materials Group (CNBM).

Shareholding: State-owned enterprise under CNBM, China’s largest cement and equipment provider.

Though Chinese, Sinoma is deeply embedded in Africa’s cement landscape as a turnkey plant constructor and operator.

Highlights:

- EPC provider for 15+ cement plants in Africa.

- Operates joint ventures in Angola, Nigeria, and Tanzania.

Sinoma is recognised for constructing high-capacity plants (up to 6 MTPA) utilising energy-efficient pre-calciner kilns and Waste Heat Recovery (WHR) technology.

7. Twiga Cement (Tanzania Portland Cement Company)

Founded: 1959 by the Tanzanian government with technical assistance from Blue Circle Industries (UK).

Shareholding: The majority is owned by Heidelberg Materials (Germany) and is listed on the Dar es Salaam Stock Exchange.

A subsidiary of Heidelberg Materials, Twiga Cement is Tanzania’s largest cement manufacturer, renowned for its innovation and reliability.

Capacity:

- 2.0 MTPA.

- Continuous 7-day dispatch operations.

Flagship Projects:

- Dar es Salaam Bus Rapid Transit.

- Tanzania Standard Gauge Railway (SGR).

Twiga’s marine cement is specially formulated to resist chloride-induced corrosion in coastal structures.

8. Ciments du Sahel (Senegal)

Founded: 2002 by the Late Dr. Latfallah Layousse.

Shareholding: Privately owned Senegalese firm; no foreign majority ownership.

Ciments du Sahel is vital to Senegal’s infrastructure development and exports to neighboring Sahelian countries.

Capacity:

- 3.5 MTPA.

- Exports to Mali, Gambia, and Guinea-Bissau.

The manufacturer has a portside grinding unit near Dakar that enables efficient bulk delivery across West Africa.

9. Sephaku Cement (South Africa)

Founded: 2006 as a subsidiary of Sephaku Holdings Limited.

Shareholding: Dangote Cement PLC holds a 64% controlling interest.

Sephaku Cement, a Dangote-backed firm, delivers high-performance cements optimised for South African market conditions.

Capacity:

- 2.2 MTPA.

- ISO/IEC 17025-certified labs.

Project Focus:

- Precast factories.

- Transport infrastructure.

Sephaku’s high early-strength CEM I is favoured in fast-track projects such as industrial parks and toll roads.

10. Savannah Cement (Kenya)

Founded: 2012 by a consortium of Kenyan investors, such as investor Benson Ndeta, and private equity groups like Savannah Heights, while the Chinese investors hold their shares through Wanho International Limited and ACME Wanji Investment Limited.

Shareholding: Privately owned with majority local ownership.

As an agile, locally owned firm, Savannah Cement is one of the top cement brands in Kenya, competing with global players and others on the African continent. This is why it had to include it in our list of the top 10 cement brands in Africa.

Capacity:

- 1.5 MTPA.

- Strong regional retail network.

Differentiators:

- Fast dispatch and low lead times.

- Popular in private housing and ready-mix concrete applications.

Savannah is investing in low-carbon options and Supplementary Cementitious Materials (SCMs) for improved performance.

Statistical Overview of Top 10 Cement Brands in Africa

|

Cement Brand |

Installed Capacity (MTPA) |

Country of Origin |

Key Countries of Operation |

|

Dangote Cement |

51.6 |

Nigeria |

Nigeria, Ethiopia, Ghana, SA |

|

Lafarge Africa |

12.0+ |

Switzerland |

Nigeria, Uganda, Malawi |

|

CIMAF |

10.0+ |

Morocco |

15+ countries |

|

Sinoma Intl |

5.0+ |

China |

Nigeria, Angola, Tanzania |

|

Ciments du Sahel |

3.5 |

Senegal |

Senegal, Mali, Gambia |

|

Mugher Cement |

2.3 |

Ethiopia |

Ethiopia |

|

Bamburi Cement |

2.3 |

Kenya |

Kenya, Uganda |

|

Sephaku Cement |

2.2 |

South Africa |

South Africa |

|

Twiga Cement |

2.0 |

Tanzania |

Tanzania |

|

Savannah Cement |

1.5 |

Kenya |

Kenya |

Overview of Cement Consumption in Africa (2015–2025)

The line graph below illustrates the steady rise in cement consumption across Africa over a decade, majorly from the top 10 cement brands in Africa, reflecting the continent’s accelerated infrastructure development. From 180 Million Metric Tonnes (MMT) in 2015 to a projected 290 MMT in 2025, the data showcases robust growth driven by urbanisation, housing demand, and large-scale public works.

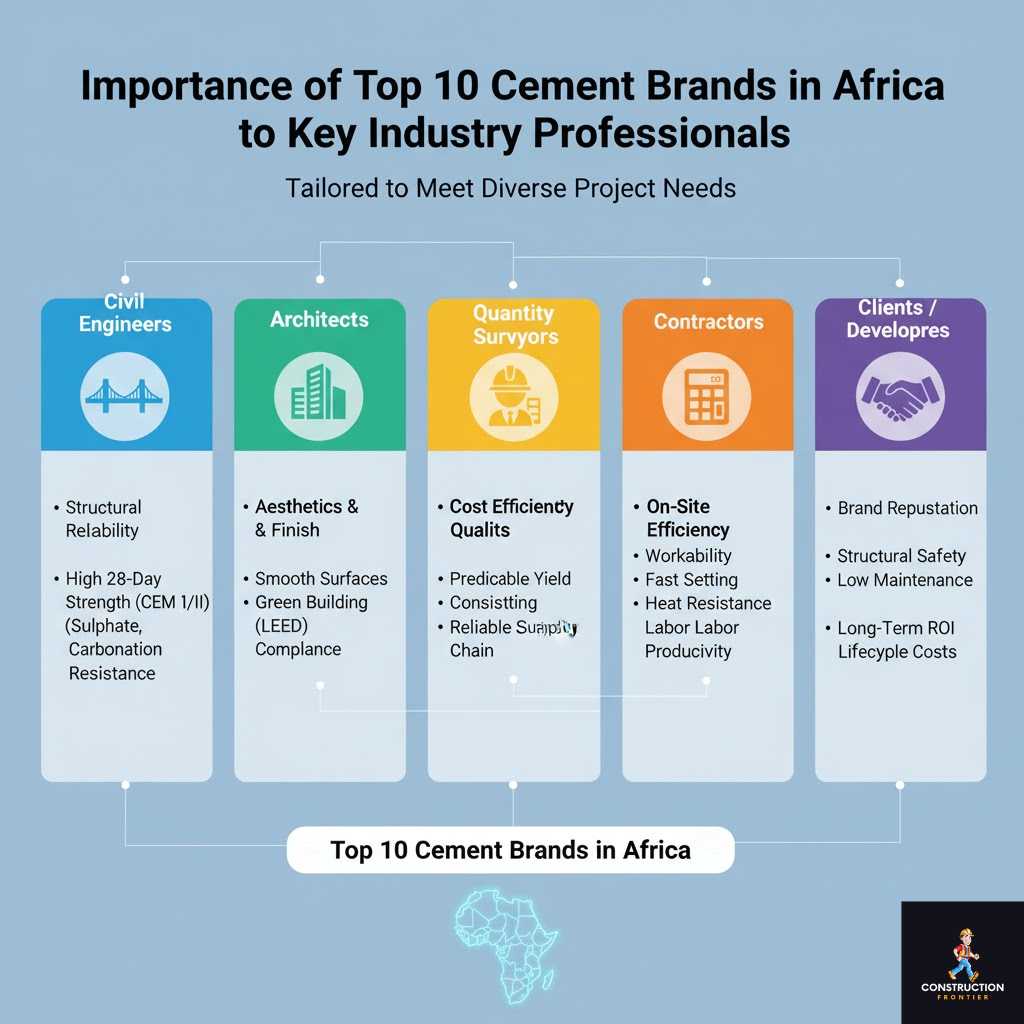

Importance of Top 10 Cement Brands in Africa to Key Industry Professionals

Different construction professionals interact with cement products in specialised ways, depending on their roles, project objectives, and performance expectations. Understanding how each stakeholder evaluates and uses cement ensures better alignment between product capabilities and real-world demands. This section breaks down the specific preferences, technical criteria, and expectations across key industry role-takers based on their experience with the top 10 cement brands in Africa.

1. Civil Engineers

Civil engineers prioritise performance metrics that ensure the infrastructure’s structural reliability and long-term durability. They typically prefer CEM I and CEM II types that achieve high 28-day compressive strength, suitable for columns, beams, and slabs. Additionally, resistance to sulphate attacks, carbonation, and alkali-silica reaction is crucial in prolonging the service life of concrete, especially in aggressive environments.

2. Architects

Architects often specify cement types that deliver superior aesthetics and sustainability. Smooth finish cements are essential for exposed concrete surfaces in modern architectural designs. Furthermore, eco-friendly cement options that support green building standards, such as Leadership in Energy and Environmental Design (LEED) certification, are increasingly in demand.

3. Quantity Surveyors

Quantity surveyors are concerned with cost estimation and material efficiency. They favour cement brands with predictable yield, consistent water-cement ratio, and minimal variability across batches. Reliable supply chain options—in both bagged and bulk forms—are key to maintaining cost controls and accurate forecasting.

4. Contractors

Contractors focus on practical considerations that affect construction speed and adaptability on-site. They look for cement types that offer good workability, resist heat in high-temperature environments, and support fast setting to remove formwork quickly. These properties directly impact labour productivity and project scheduling. They also conduct extensive market analysis of innovative construction materials, such as the cement production market. They are always on the lookout for listings, including the top 10 cement brands in Africa or globally.

5. Clients

Clients and real estate developers prioritise cement brands with a strong track record of performance and low maintenance requirements, such as the top 10 cement brands listed above in Africa. A well-established brand reputation gives them confidence in structural safety, while reduced lifecycle costs help optimise return on investment in public and private developments.

Emerging Trends in Africa’s Cement Sector

As Africa’s construction sector advances into the future, cement manufacturers are investing in advanced technologies and sustainable practices to remain competitive and compliant with global standards. These innovations transform the production, transportation, and application of cement across infrastructure projects. Below are key trends shaping the next phase of growth and resilience in the African cement industry, which in turn impact the top 10 cement brands in Africa.

- Clinker Substitution: This involves replacing a portion of energy-intensive clinker with supplementary cementitious materials, such as calcined clay, rice husk ash, and pozzolana. This strategy reduces carbon emissions and leverages locally available resources, lowering environmental impact and production costs.

- Digital Plant Monitoring: Integrating Artificial Intelligence (AI) and Internet of Things (IoT) technologies into cement plants enhances process control, predictive maintenance, energy management, and real-time quality assurance. This leads to improved operational efficiency and reduced downtime.

- Green Logistics: Cement companies are increasingly adopting electric trucks, rail-supported bulk transport, and optimised routing systems to reduce fuel consumption and transportation emissions. These innovations support Environmental, Social, and Governance (ESG) goals and cut logistics costs.

- Carbon Pricing Compliance: As Africa aligns with global sustainability frameworks, the top 10 cement brands in Africa are proactively adjusting operations to meet upcoming carbon taxation and emissions trading regulations. This includes investment in Carbon Capture and Storage (CCS) and Carbon Accounting (CA) systems.

- Localisation: Brands are developing cement formulations tailored to each country’s unique geotechnical and climatic conditions. These formulations enhance durability and structural performance in specific regions by addressing local variations in soil chemistry, temperature, and humidity.

Conclusion

Africa’s construction future depends heavily on the availability and quality of cement. These top 10 cement brands in Africa are market leaders and strategic enablers of progress. Civil engineers, contractors, architects, and developers must assess these brands beyond cost, considering factors such as strength, workability, sustainability, and regional suitability.

From Dangote’s pan-African reach to Savannah Cement’s reliability in Kenya, these companies are building the highways, skyscrapers, and cities of tomorrow. Partnering with the right cement supplier ensures that every mix poured today stands strong for generations.

Explore More Construction Insights

Stay updated on global construction trends, African construction trends, project management tips, and civil engineering materials:

Visit constructionfrontier—your go-to platform for civil engineering and construction intelligence.