Zoomlion AI Robots Deliver Proven 6-Minute Excavator Production

Zoomlion AI robots have achieved a breakthrough in automated excavator production, delivering fully assembled machines in as little as six minutes. The milestone signals a major leap in AI-driven construction equipment manufacturing and positions Zoomlion at the forefront of global smart factory innovation.

Zoomlion AI Robots Redefine Excavator Manufacturing Speed

At the centre of this transformation is Zoomlion’s Excavation Machinery Smart Factory, a facility engineered to operate as a single, data-connected system rather than isolated production lines.

Key characteristics of the factory include:

- End-to-end digital integration from raw material intake to final inspection.

- AI-controlled production scheduling and robotic task allocation.

- Industrial Internet of Things (IIoT) connectivity across machines, robots, and logistics systems.

- Digital twin technology for real-time simulation and optimisation.

More than 80 percent of the manufacturing processes inside the facility operate under AI-assisted or AI-controlled decision-making. This includes welding, machining, painting, assembly sequencing, internal logistics, and quality inspection.

For engineers familiar with the complexity of excavator production, this level of automation represents a fundamental departure from conventional factory layouts that rely on manual intervention at multiple critical stages.

Inside Zoomlion’s Smart Factory Technology

At the centre of this milestone sits Zoomlion smart factory technology, which integrates artificial intelligence, robotics, digital twins, and real-time data orchestration into a unified production environment. The smart factory can produce an excavator every 6 minutes, a scissor lift every 7.5 minutes, a truck crane every 18 minutes and a concrete pump every 27 minutes.

Key components of the Zoomlion automated excavator factory include:

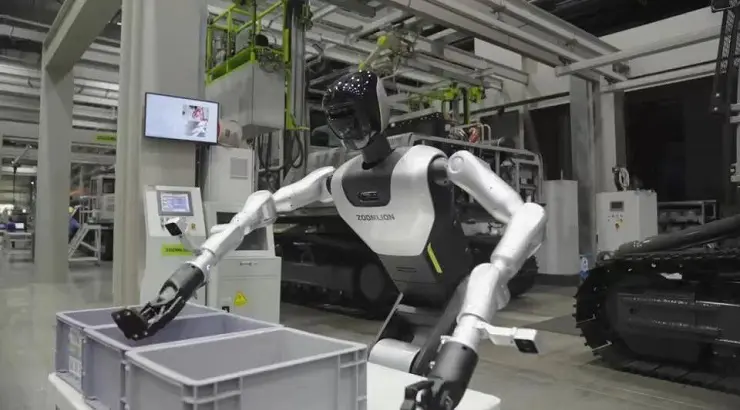

- AI-powered humanoid and articulated robots handling precision assembly.

- Automated logistics systems supply components in real time.

- Machine vision for quality inspection and alignment.

- Digital control platforms synchronise every production step.

This level of coordination enables automated excavator production to operate continuously with minimal human intervention, while maintaining tight tolerances and quality consistency.

How Zoomlion AI Robots Build Excavators in Six Minutes

The six-minute excavator production headline is not the result of a single high-speed workstation. Instead, it reflects a takt-time achievement enabled by distributed AI robots operating in synchronised production cells.

How Zoomlion AI robots achieve high throughput:

- Autonomous guided vehicles (AGVs) transport thousands of components daily without human drivers.

- Robotic arms perform chassis alignment, component placement, and fastening with millimetre precision.

- Vision-based AI inspection systems validate quality at multiple checkpoints.

- Machine-learning algorithms dynamically rebalance workloads to prevent bottlenecks.

Each excavator progresses through the factory without stopping for manual rescheduling or line changeovers. Multiple excavator models are produced simultaneously, eliminating downtime traditionally associated with configuration changes.

This approach allows Zoomlion AI robots to maintain a consistent output rhythm, rather than relying on bursts of productivity followed by delays.

Zoomlion AI Robots in Construction Equipment Move from Support to Core Production

Historically, robotics in heavy manufacturing supported repetitive or hazardous tasks. The Zoomlion breakthrough shows a different reality.

Today, AI robots are used in construction equipment production now

- Coordinate across multiple assembly stages.

- Adapt dynamically to component variation.

- Learn from performance data across production cycles.

- Operate at speeds unattainable by traditional lines.

This shift places robotics at the strategic centre of manufacturing rather than the periphery.

Further Reading: Volvo CE Excavator Factory in Sweden Signals Strong Growth

Smart Manufacturing in Construction Reaches a Turning Point

The use of AI robots in construction equipment manufacturing addresses a long-standing challenge in the industry: high product variability.

Excavators differ by:

- Operating weight

- Boom and arm configurations

- Hydraulic systems

- Emissions standards

- Market-specific specifications

Historically, this variability limited automation potential. Zoomlion’s smart manufacturing system overcomes this by modularising production tasks and allowing AI systems to adapt workflows in real time.

As a result:

- Manufacturing lead time has dropped to approximately 6.5 days from steel cutting to finished excavator.

- Inventory requirements have reduced through make-to-order production.

- Production errors and rework rates have declined due to AI-assisted quality control.

For construction professionals, this signals a future where equipment availability becomes faster, more predictable, and less constrained by factory capacity.

Strategic Implications for Global Equipment Manufacturers

The implications of Zoomlion AI robots extend well beyond a single factory.

1. Competitive Pressure Intensifies

Manufacturers that rely on conventional assembly lines face widening cost and speed disadvantages.

2. Capital Strategy Shifts

Investment priorities increasingly favour software, AI models, and robotics over incremental plant expansion.

3. Workforce Transformation

Human roles shift toward supervision, optimisation, and system intelligence rather than manual assembly.

These changes redefine what leadership means in construction equipment robotics.

Zoomlion Excavator Manufacturing and Global Positioning

The breakthrough reinforces Zoomlion’s ambition to lead not only in volume but in manufacturing sophistication.

Within Zoomlion excavator manufacturing, AI-driven systems now enable:

- Faster response to market demand fluctuations.

- Consistent build quality across production runs.

- Reduced dependency on labour availability.

- Scalable output without proportional cost increases.

This strengthens Zoomlion’s position in global markets where pricing pressure and delivery timelines increasingly determine contract awards.

AI-Driven Construction Equipment Production and Cost Structure

One of the most significant outcomes of AI-driven construction equipment production lies in cost predictability.

AI-enabled factories reduce:

- Downtime through predictive system monitoring.

- Rework through continuous quality feedback.

- Inventory waste via just-in-time robotic logistics.

Over time, these efficiencies compress unit costs and stabilise margins, even in volatile economic conditions.

What the Zoomlion Automated Excavator Factory Means for the Industry

The Zoomlion automated excavator factory sets a new benchmark that competitors cannot ignore.

Industry-wide consequences include:

- Acceleration of smart factory investments.

- Greater emphasis on AI capability as a competitive differentiator.

- Increased consolidation pressure on manufacturers unable to modernise.

In this context, Zoomlion AI robots build excavators not only faster, but redefine industry expectations.

Construction Equipment, Robotics, and Supply Chain Resilience

Beyond speed, robotics improves resilience. Automated systems reduce exposure to labour disruptions, skills shortages, and regional workforce constraints.

This matters in an era marked by:

- Geopolitical supply chain uncertainty.

- Rising labour costs.

- Increasing regulatory complexity.

By embedding intelligence directly into production, construction equipment robotics supports long-term manufacturing stability.

Risks and Execution Challenges Remain

Despite its promise, large-scale AI automation carries risks that will shape long-term outcomes.

Key challenges include:

- High upfront capital investment.

- Cybersecurity and data integrity risks.

- Dependence on software reliability.

- Talent shortages in AI systems management.

Success depends on disciplined execution, continuous system learning, and robust governance frameworks.

What Zoomlion AI Robots Mean for the Construction Industry

The impact of Zoomlion AI robots extends beyond factory walls.

1. For Contractors and Fleet Owners

- Faster equipment delivery timelines.

- Improved product consistency.

- Greater confidence in supply availability during demand surges.

2. For Competing Manufacturers

- Pressure to invest in smart manufacturing infrastructure.

- Reduced tolerance for legacy, labour-intensive production models.

- Increased importance of digital transformation strategies.

3. For Engineers and Industry Planners

- New benchmarks for plant design and automation integration.

- Expanded role of AI and data analytics in industrial engineering.

- Closer alignment between manufacturing, design, and after-sales systems.

The era where scale alone defined manufacturing leadership is ending. Intelligence now defines competitiveness.

Further Reading: Caterpillar Limited Edition Machines Celebrate 100 Years

A Glimpse into the Future of Heavy Equipment Manufacturing

Zoomlion’s automated excavator factory provides a glimpse into the future of robotic manufacturing in the construction industry.

Key trends likely to accelerate include:

- Wider adoption of digital twins in heavy equipment plants.

- AI-based predictive maintenance embedded into production systems.

- Seamless integration between factory data and field performance data.

- Shorter product development cycles driven by manufacturing feedback loops.

As global infrastructure demand grows and labour constraints tighten, manufacturers capable of combining robotics, AI, and data at scale will shape the next phase of construction equipment evolution.

Conclusion: Zoomlion AI Robots Set a New Global Benchmark

The achievement by Zoomlion AI robots represents a structural shift in how construction equipment gets built. Delivering an excavator in six minutes moves AI and robotics from theoretical advantage to proven industrial capability.

As AI robots in construction equipment reshape manufacturing economics, Zoomlion’s smart factory stands as a reference point for the entire sector. The message to the industry is clear. The future of heavy equipment manufacturing belongs to those who master intelligent automation at scale.

Stay Ahead of Smart Manufacturing and Construction Robotics Trends

For thinker-led insights on construction equipment innovation, AI-driven manufacturing, and industrial strategy shaping Africa and global markets, explore more expert analysis at ConstructionFrontier.com.