Brick-Laying Robot: Transforming Construction with Advanced Automation and Speed

Brick-laying robots are reshaping modern construction by combining speed, precision, and cost-efficiency. Discover how these machines are redefining masonry and the future of the built environment. In recent years, the brick-laying robot has gained prominence, showcasing its potential to revolutionise the construction landscape.

Brick-Laying Robot: A New Era in Construction

For centuries, the craft of bricklaying has been at the heart of building civilisation. From the Roman aqueducts to today’s skyscrapers, masonry has symbolised strength, durability, and artistry. Yet the industry faces a reality: traditional bricklaying is labour-intensive, time-consuming, and subject to human limitations. Enter the brick-laying robot, a breakthrough innovation in construction automation robots that transforms how walls, homes, and structures are built.

With the advent of the brick-laying robot, builders can now achieve unprecedented levels of efficiency and quality in their projects.

The construction sector, long resistant to rapid technological shifts, embraces robotics to overcome challenges such as skilled labour shortages, rising project costs, and demands for faster, higher-quality builds. Among these technologies, masonry robots in construction are emerging as frontrunners. These automated brick-laying robots increase productivity and redefine efficiency and consistency in a sector that has historically relied on human skill.

The brick-laying robot not only enhances productivity but also reduces the overall cost of construction.

What is a Brick-Laying Robot?

As a result, the brick-laying robot is becoming an essential tool in the modern construction toolkit.

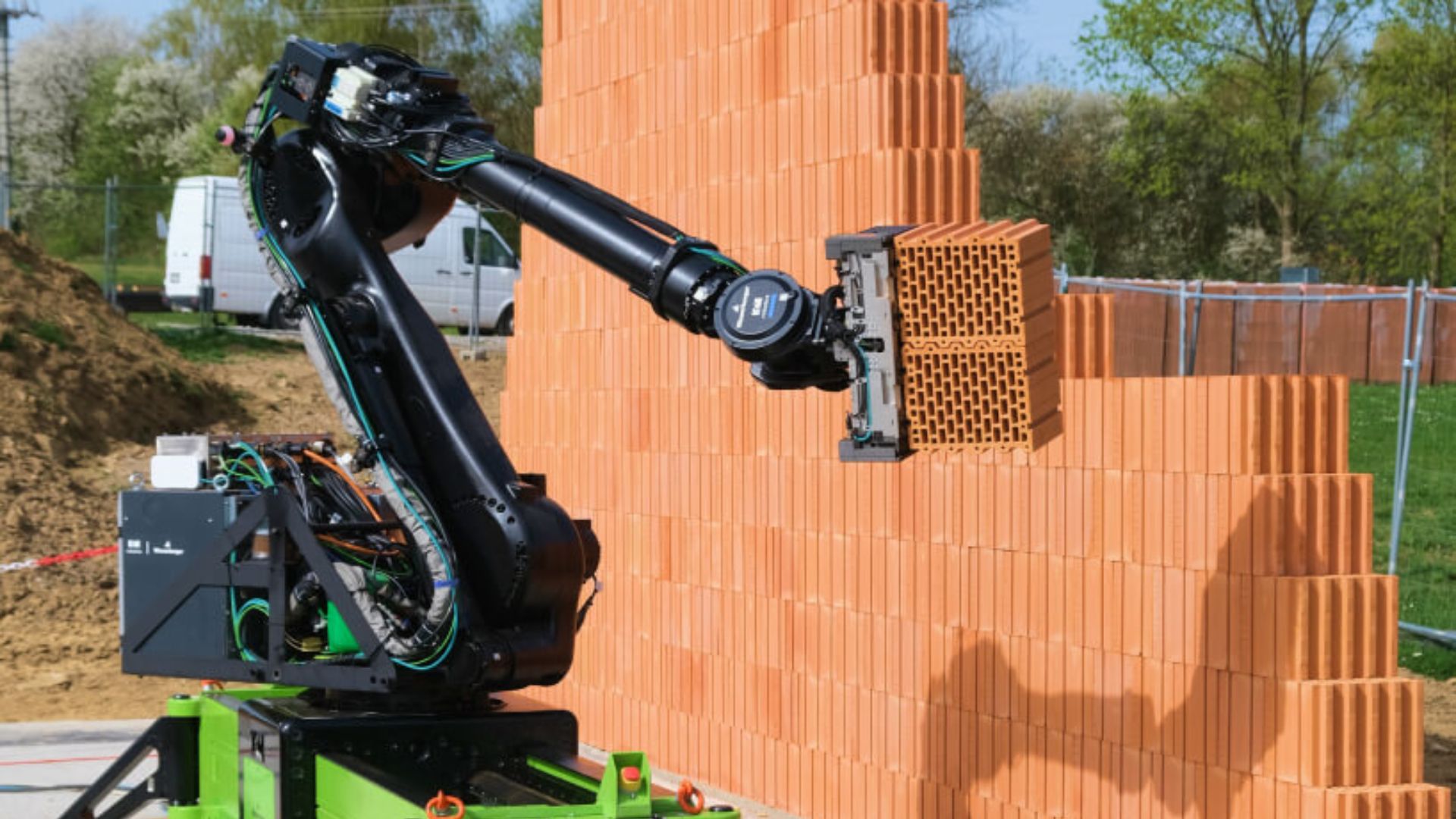

A brick-laying robot is a semi- or fully automated machine designed to precisely lay bricks guided by digital blueprints. Unlike human masons who rely on experience and endurance, these robots operate with laser-guided accuracy and can place thousands of bricks in a fraction of the time.

The most well-known example is Australia’s Hadrian X, capable of laying 1,000 bricks per hour. Equipped with advanced robotics, artificial intelligence, and 3D design integration, it can construct the shell of a home in just a few days—a task that could take weeks using traditional methods.

(Above: Hadrian X – an Australian-developed brick-laying robot.)

These machines typically feature robotic arms, automated mortar application systems, and sensors that accurately place every brick. They represent the role of robotics in modern masonry and construction, making processes faster, safer, and less dependent on manual labour.

How Brick-Laying Robots Are Transforming Construction

The introduction of the brick-laying robot has not only streamlined construction processes but also elevated the standards of quality.

The impact of brick-laying robots extends beyond speed. They are reshaping project management, labor structures, and even architectural design.

- Speed and Efficiency: A single robotic bricklayer can outperform a team of human masons, significantly shortening project timelines. This makes them invaluable in large-scale infrastructure and housing projects.

- Precision and Quality: Robots follow programmed blueprints without fatigue or error, reducing issues like uneven walls, misalignments, and structural weaknesses.

- Safety Enhancements: By taking over repetitive and physically demanding tasks, robots reduce the risk of worker injuries caused by heavy lifting or prolonged exposure to harsh working conditions.

- Scalability: In regions experiencing rapid urbanisation, like Africa and Asia, brick-laying robots will enable governments and developers to meet housing demands quickly and cost-effectively.

Simply put, brick-laying robots transform construction by delivering what human workers cannot consistently achieve—speed without compromising precision.

Future developments anticipate even more sophisticated features for the brick-laying robot, further pushing the boundaries of construction technology.

Benefits of Using a Robotic Bricklayer in Building Projects

The benefits of using a robotic bricklayer in building projects extend to every stakeholder, from contractors to developers and even clients:

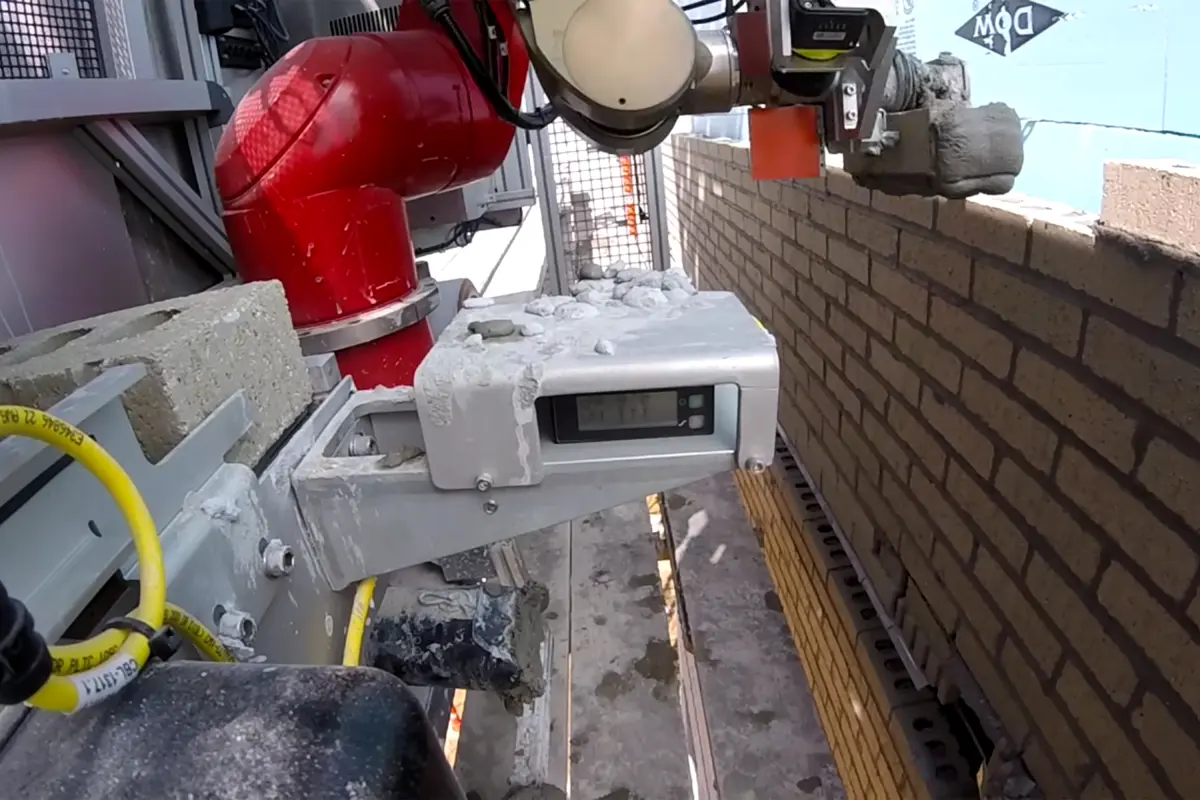

(Above: WLTR Brick-laying robot.)

- Time Savings: Robots work longer shifts without breaks, reducing build times.

- Lower Costs: Reduced reliance on large teams of masons lowers labour costs, while faster construction decreases overhead expenses.

- Improved Safety: Robots handle repetitive, labour-intensive tasks, allowing human workers to focus on supervision and creative problem-solving.

- Consistency in Quality: Uniform bricklaying ensures better structural integrity and reduced maintenance costs.

- Sustainability: Optimised mortar usage and reduced waste align with green building practices.

This is why the cost efficiency of robotic bricklayers in construction projects is becoming a central argument for their widespread adoption.

Comparison of Brick-Laying Robots vs Human Masons

Ultimately, the brick-laying robot represents a shift in how we envision and execute construction projects.

A common debate arises: will robots replace human masons? While comparing brick-laying robots to human masons reveals major differences, the answer lies in complementarity rather than replacement.

- Robots excel at speed, precision, and repetitive tasks. They can work in hazardous environments without fatigue and ensure uniform quality.

- Humans bring adaptability, problem-solving, and artistry. Complex architectural designs, unique patterns, and on-the-fly adjustments require skilled masons.

Thus, the future isn’t about replacing the other but about collaboration. Robots will handle bulk bricklaying, while human workers will oversee, manage, and specialise in tasks requiring creativity and craftsmanship.

Future of Construction with Brick-Laying Automation

The future of construction with brick-laying automation is promising and transformative. As robotics technology advances, we can expect:

- Smarter Integration: Robots connected to Building Information Modelling (BIM) systems for seamless project execution.

- Global Adoption: More countries use these machines to meet housing demands, especially in emerging markets.

- Workforce Transformation: Masons transitioning into supervisors, robot operators, and quality control experts.

- Sustainable Construction: Automation reduces waste, optimises material use, and supports eco-friendly building practices.

In the coming decades, construction sites could resemble highly automated, efficient, and predictable manufacturing plants.

Why They Lead: Role of Robotics in Modern Masonry and Construction

Brick-laying robots symbolise the broader role of robotics in modern masonry and construction: bridging the gap between human limitations and the industry’s demand for faster, smarter, and more sustainable solutions.

(Above: Semi-Automated Mason – SAM.)

They lead because they address the three pillars of modern construction:

- Productivity: Faster completion times and lower costs.

- Safety: Reduced exposure of workers to risky, strenuous jobs.

- Sustainability: Minimising material waste and maximising efficiency.

Companies investing in these technologies are not just future-proofing their operations but setting benchmarks for a new construction standard.

Conclusion: Building Tomorrow with Brick-Laying Robots

The brick-laying robot is more than a machine; it symbolises transformation in the construction industry. By blending speed, precision, and cost efficiency, these machines address the long-standing challenges of labour shortages, rising costs, and safety risks.

In summary, the brick-laying robot stands at the forefront of innovation, driving change within the industry. While human masons will remain vital for creativity and oversight, the synergy between people and machines paves the way for a more sustainable, efficient, and resilient built environment. As adoption grows, brick-laying robots will not just build walls—they will help build the future of construction itself.

Stay Updated with the Latest Construction Updates

Are you curious about the future of automation and autonomy in the construction industry and how automation is changing infrastructure across the globe? Dive deeper into insights, case studies, and innovations at ConstructionFrontier.com, your trusted source for construction technology and industry trends.